Chain manner stitch seam button sewing machine and button sewing method

A button sewing machine and chain stitch technology, applied to sewing machine components, sewing equipment, cloth pressing mechanism, etc., can solve the problems of tearing the cloth surface C1, reducing the sewing strength of button B, and the button B is easy to fall off, etc. Achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] (overall structure of the embodiment)

[0039] Hereinafter, a button sewing machine 100 according to an embodiment of the present invention will be described with reference to FIGS. 1 to 7 .

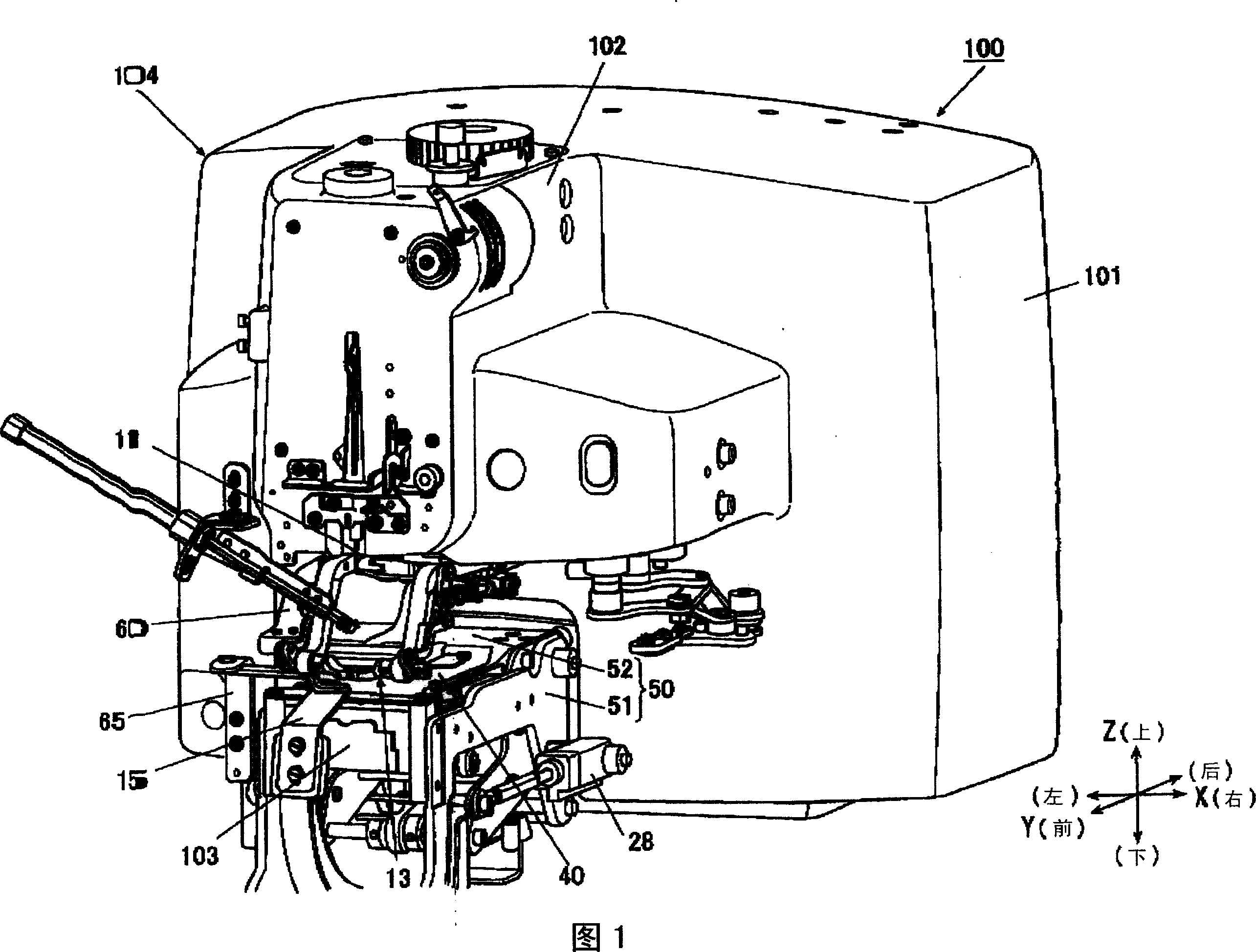

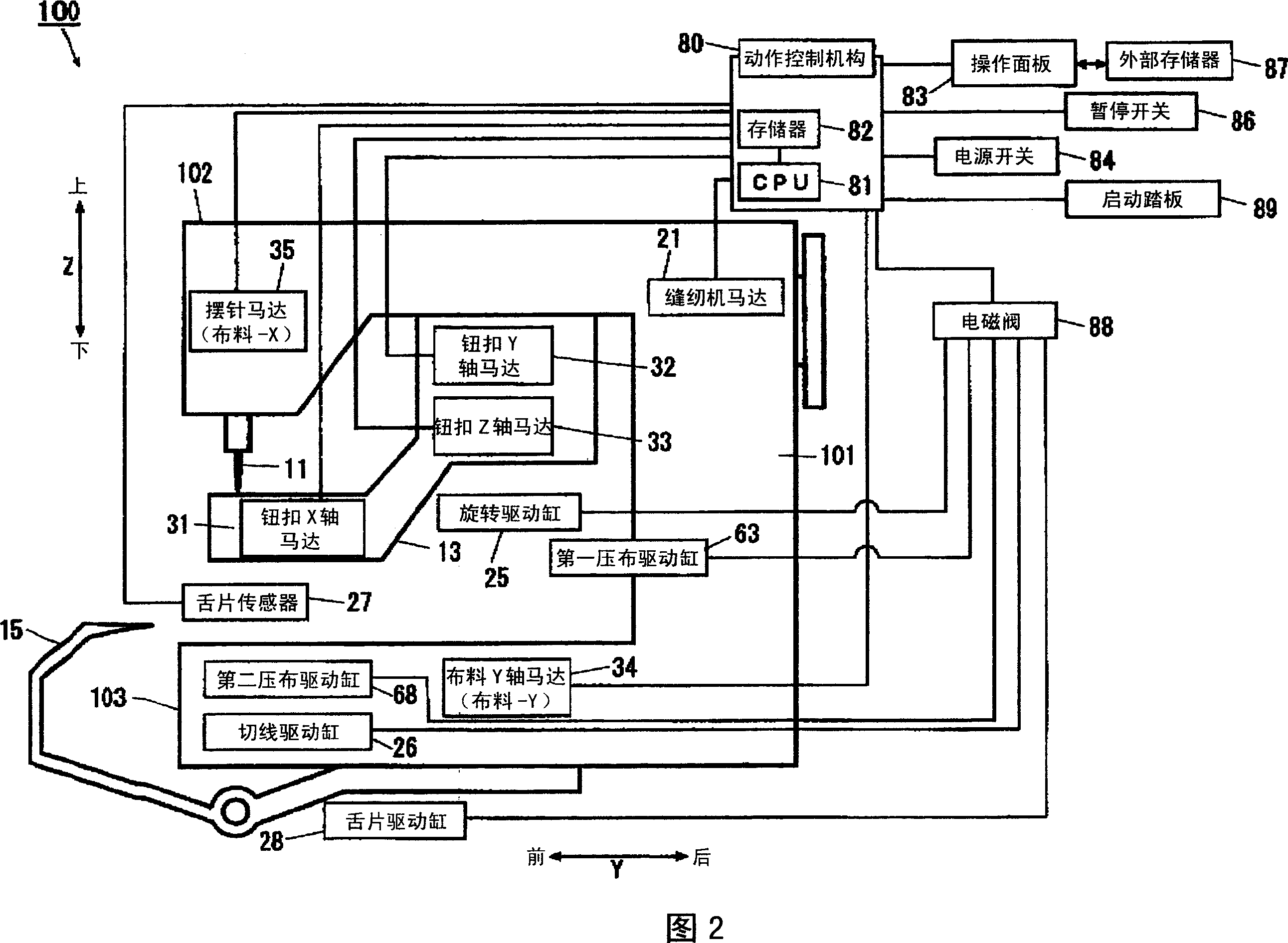

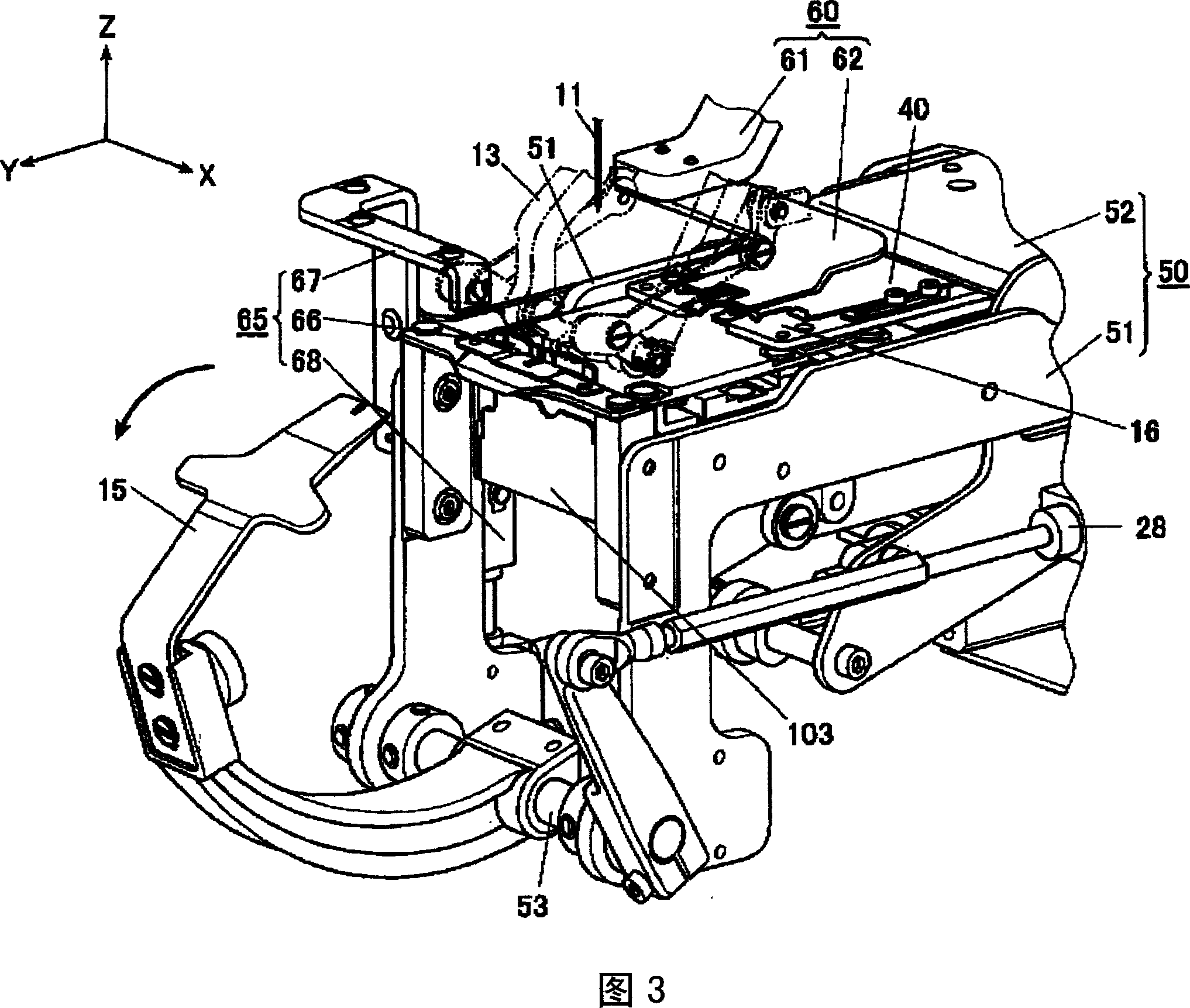

[0040] FIG. 1 is an overall perspective view of the button sewing machine 100 , and FIG. 2 is a block diagram showing the main configuration of the button sewing machine 100 .

[0041] The whole button sewing machine 100 is composed of: a sewing machine base plate 103 located at its lower portion, a sewing machine vertical body portion 101 erected upward from one end portion behind the sewing machine base plate 103, and a sewing machine vertical body portion 101 extending along the sewing machine base plate 103 from above the sewing machine vertical body portion 101. The sewing machine cross arm 102 provided constitutes, and its general external shape constituted by them is formed in a substantially U-shape.

[0042]Furthermore, in the following description, the direction paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com