Electric field synergistic mud dewatering method and its device

A technology of sludge dewatering and electric field, applied in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of difficulty, high economic cost, and large heat consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

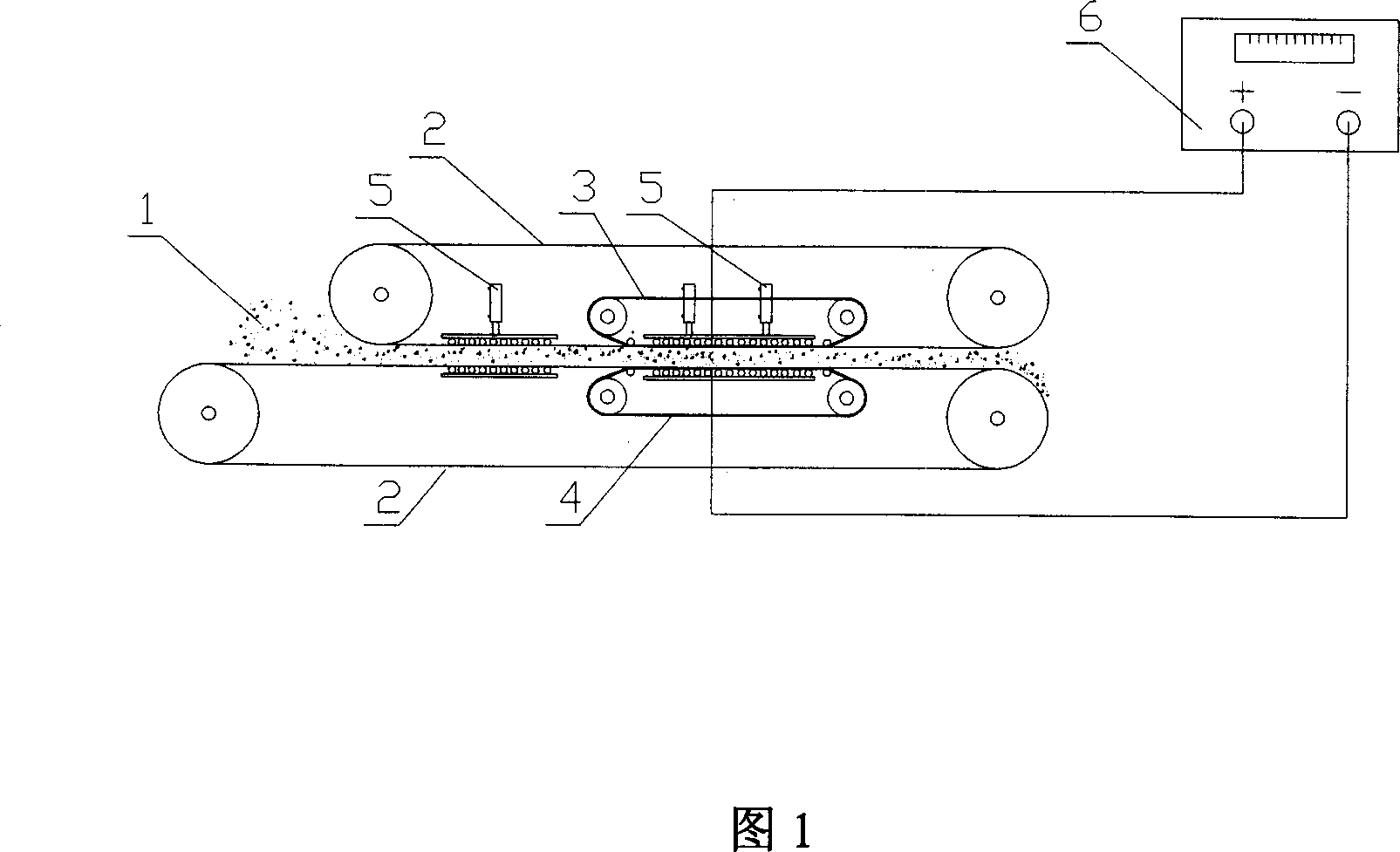

[0024] As shown in Figure 1, the dewatered cake 1 first enters the mechanical pressure action area with the movement of the filter cloth of the permeable material layer 2, and the thickness of the mud cake is 2 mm. After advancing for 2 seconds, it enters the electric field and pressure synergistic dehydration area. The metal plate-shaped anode conductor 3 is arranged on the upper side of the mud and the outer side of the filter cloth, and is connected to the positive pole of the DC power supply 6; Negative connection. Conductors can move synchronously with the movement of filter cloth and sludge. On the upper side of the anode conductor 3, the hydraulic equipment of the mechanical pressure device 5 applies thrust to ensure the close contact between the electrode and the filter cloth and sludge, and provides a mechanical pressure of 5000Pa. The DC power supply adopts a continuous voltage regulation method, and the power supply voltage is 5-10V. The water in the sludge passes...

Embodiment 2

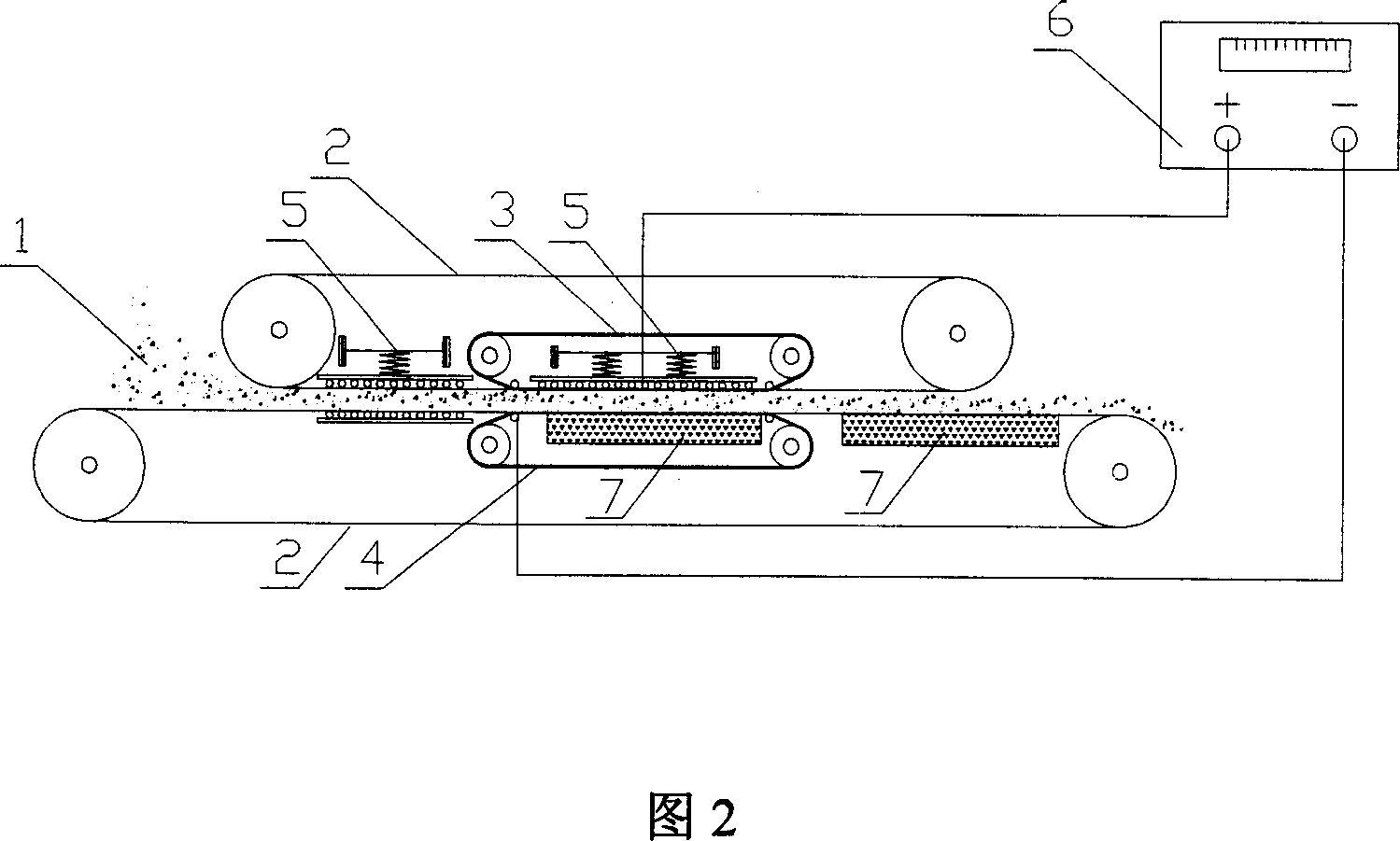

[0026] As shown in Figure 2, the dewatered cake 1 first enters the mechanical pressure action zone with the movement of the filter cloth 2 of the permeable material layer, and the thickness of the mud cake is 5mm. After advancing for 5 seconds, it enters the electric field and pressure synergistic dehydration zone. A metal plate-shaped anode conductor 3 is arranged on the upper side of the sludge and the outer side of the filter cloth in this section, and is connected to the positive pole of the DC power supply 6; a metal mesh cathode conductor 4 is arranged on the lower side of the sludge and the outer side of the filter cloth, and is connected to the positive pole of the DC power supply 6. Negative connection of power supply 6. Conductors can move synchronously with the movement of filter cloth and sludge. On the upper side of the anode conductor 3, a thrust is applied by the mechanical pressure device 5 of the pre-compressed spring mechanical device to ensure the close cont...

Embodiment 3

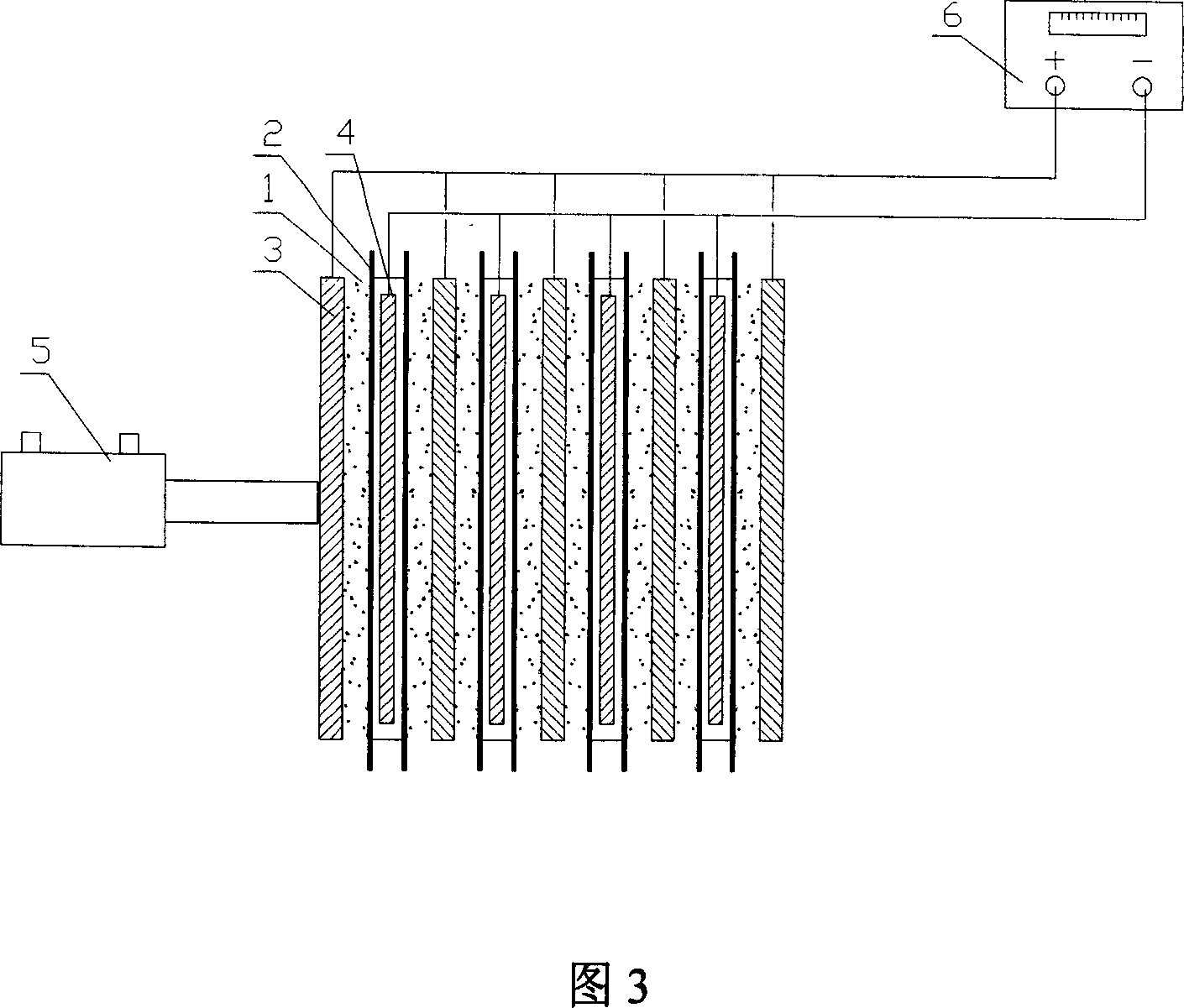

[0028]As shown in Figure 3. The mud cake 1 is placed between the anode conductor 3 of the metal plate and the metal plate-shaped cathode conductor 4 with grooves on the surface, the initial mud cake thickness is 50mm, and there is a gap between the cathode conductor 4 and the mud cake 1 Filter cloth 2. The anode conductor 3 is connected to the positive pole of the DC power supply 6 , and the cathode conductor 4 is connected to the negative pole of the DC power supply 6 . The DC power supply adopts a continuous power supply mode, and the supply voltage is 60-80V. The mechanical pressure of 10000Pa is provided by the hydraulic device 5 . When dehydrating sludge, first apply mechanical pressure for 10 seconds, and then turn on the power switch. Under the synergistic effect of electric field and mechanical pressure, the water in the sludge moves to the cathode conductor 4 and then flows out along the groove on the surface to complete the dehydration process. After the dehydrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com