Method for producing thermal-formation products of plastic sheet material

A technology of a plastic sheet and a production method, which is applied to the production field of plastic sheet thermoforming products, can solve the problems of high printing cost, complicated printing process, easy to contaminate food, etc., and achieves low printing cost, simple pattern printing process, and avoidance of Effects of contaminated food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

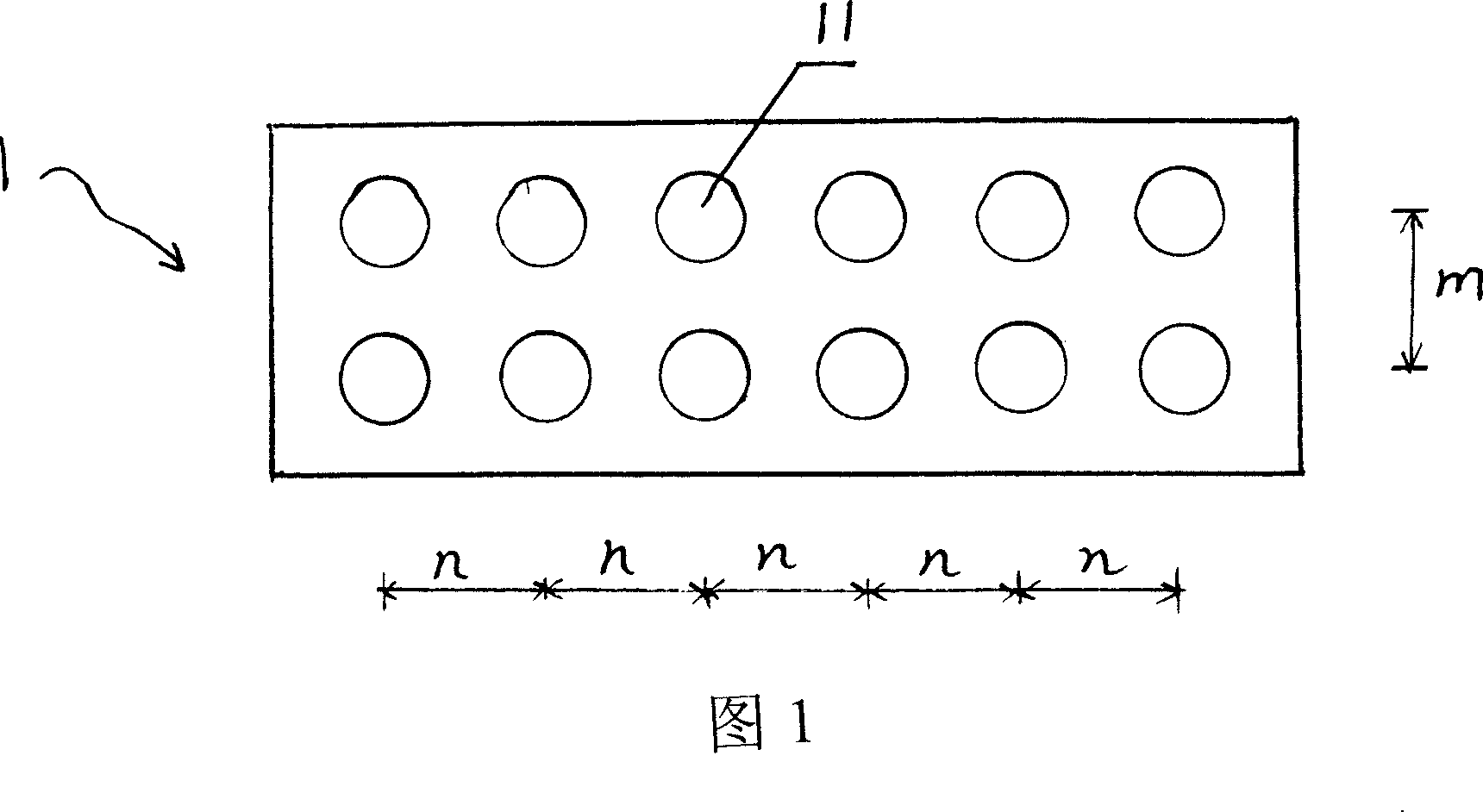

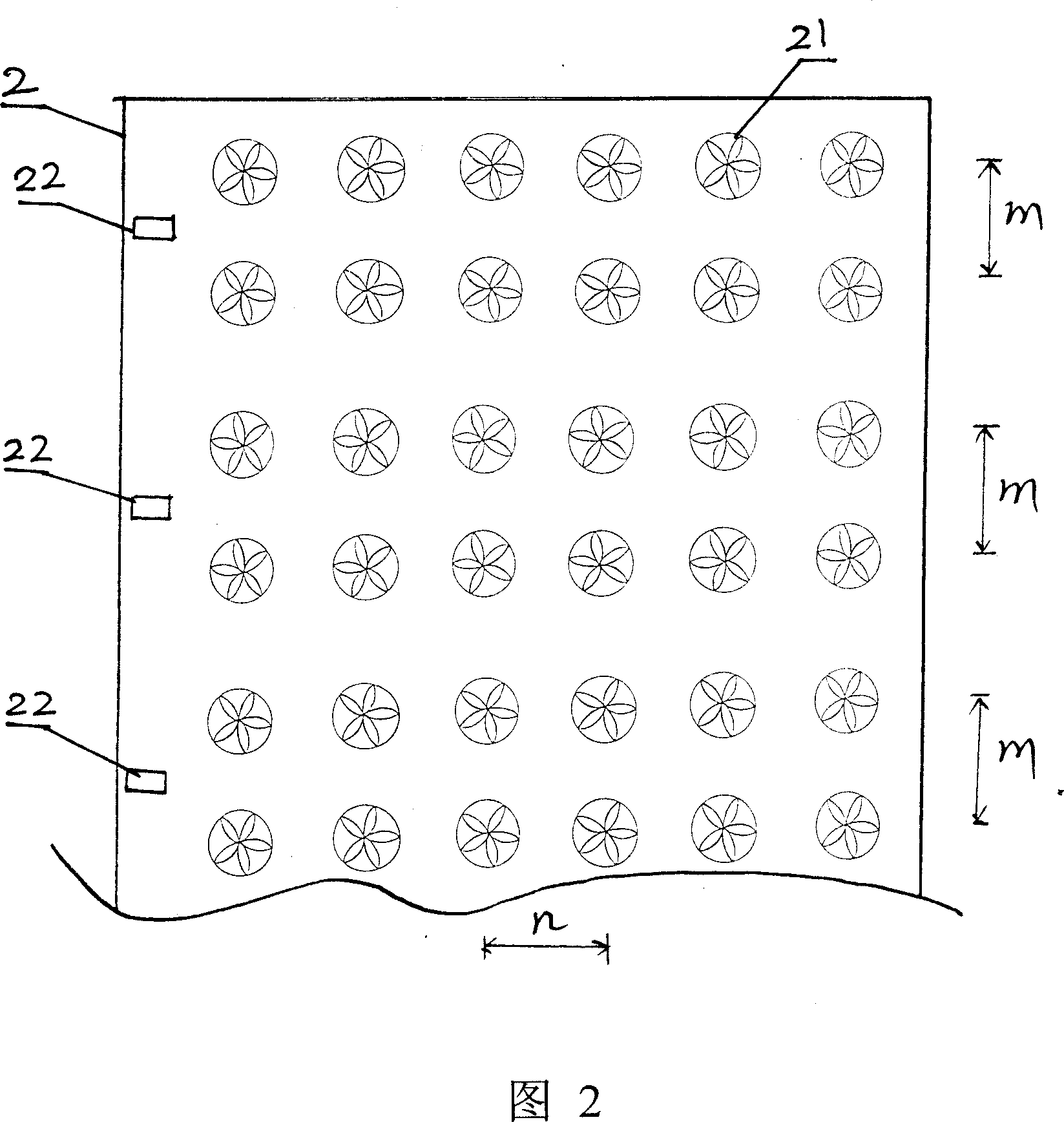

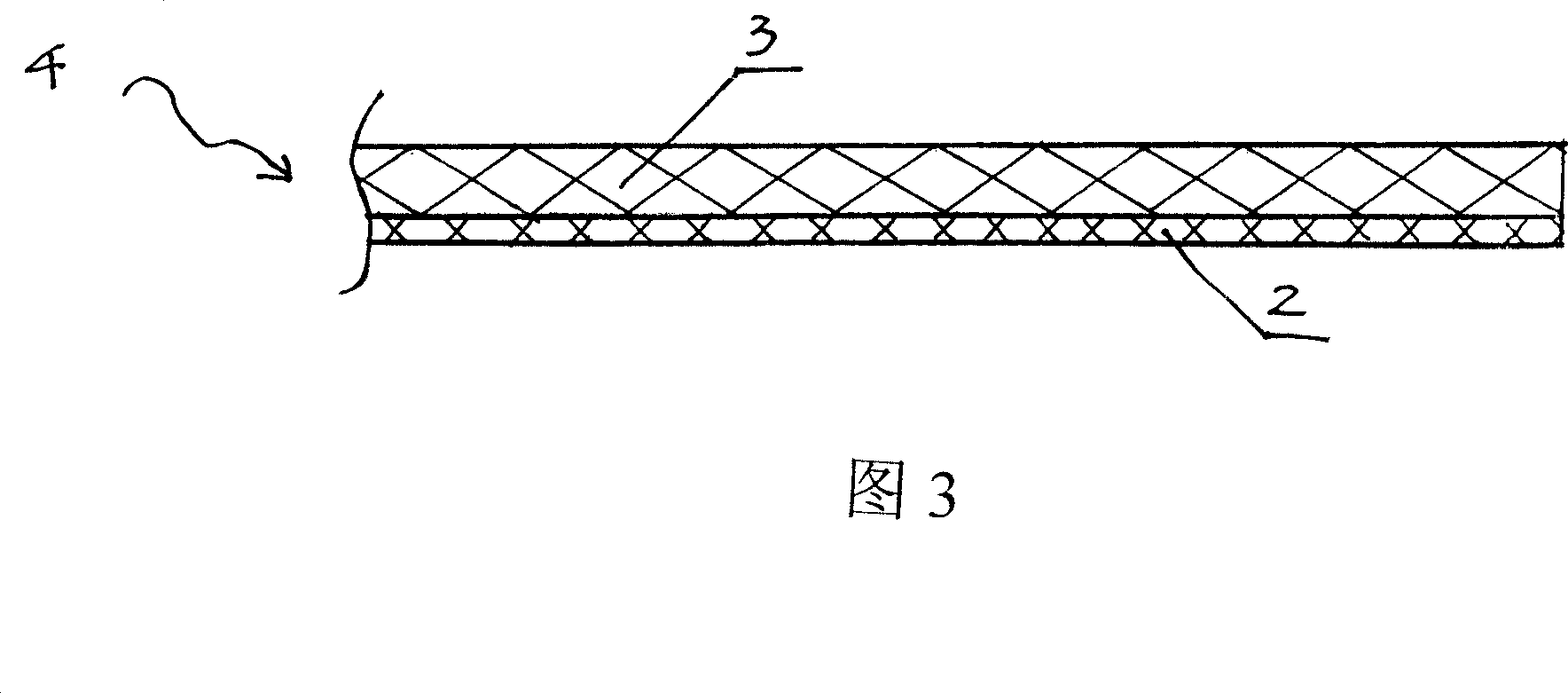

[0019] This embodiment adopts blow molding process (positive pressure molding process) to manufacture plastic cups, as shown in Fig. is m, and the column distance is n; the production method of this embodiment comprises the following main steps in turn: (1), on one side of the transparent plastic film 2, a plurality of plum blossom patterns 21 are printed, and the patterns are divided into multiple groups. The number of plum blossom patterns is equal to the number of cavities in the blow mold, which is 12. The patterns 21 of each group are distributed into two rows and six columns. The row spacing of the patterns in each group is correspondingly equal to the row spacing m of the cavity in the mold. The column distance of pattern in each group is correspondingly equal to the column distance n of each mold cavity in the mould, as shown in Figure 2; The position of the group of printed patterns constitutes a corresponding relationship (in this embodiment, this corresponding relat...

Embodiment 2

[0021] This embodiment adopts the plastic-absorbing process (vacuum negative pressure forming process) to manufacture plastic handicrafts. The main steps of this embodiment are basically the same as those in Embodiment 1, except that this embodiment adopts the plastic-absorbing process to form, and the cavities in the mold are only arranged in a row. Each group of patterns printed in the plastic film is also distributed in a row, and the horizontal spacing of the patterns in each group corresponds to the horizontal spacing of each cavity in the mould; and an opaque plastic sheet is used to compound with a transparent plastic film. The plastic product that this embodiment obtains is plastic handicraft 5, and the shape of its center is close to tortoise shell shape, and as shown in Figure 5, the tortoise shell shape center position is printed with pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com