Rotary compactor

A compactor and indenter technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of complex structure, poor equipment running stability, and many running parts in the transmission part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] For technical content not mentioned below, relevant content in the prior art may be adopted or referred to for reference.

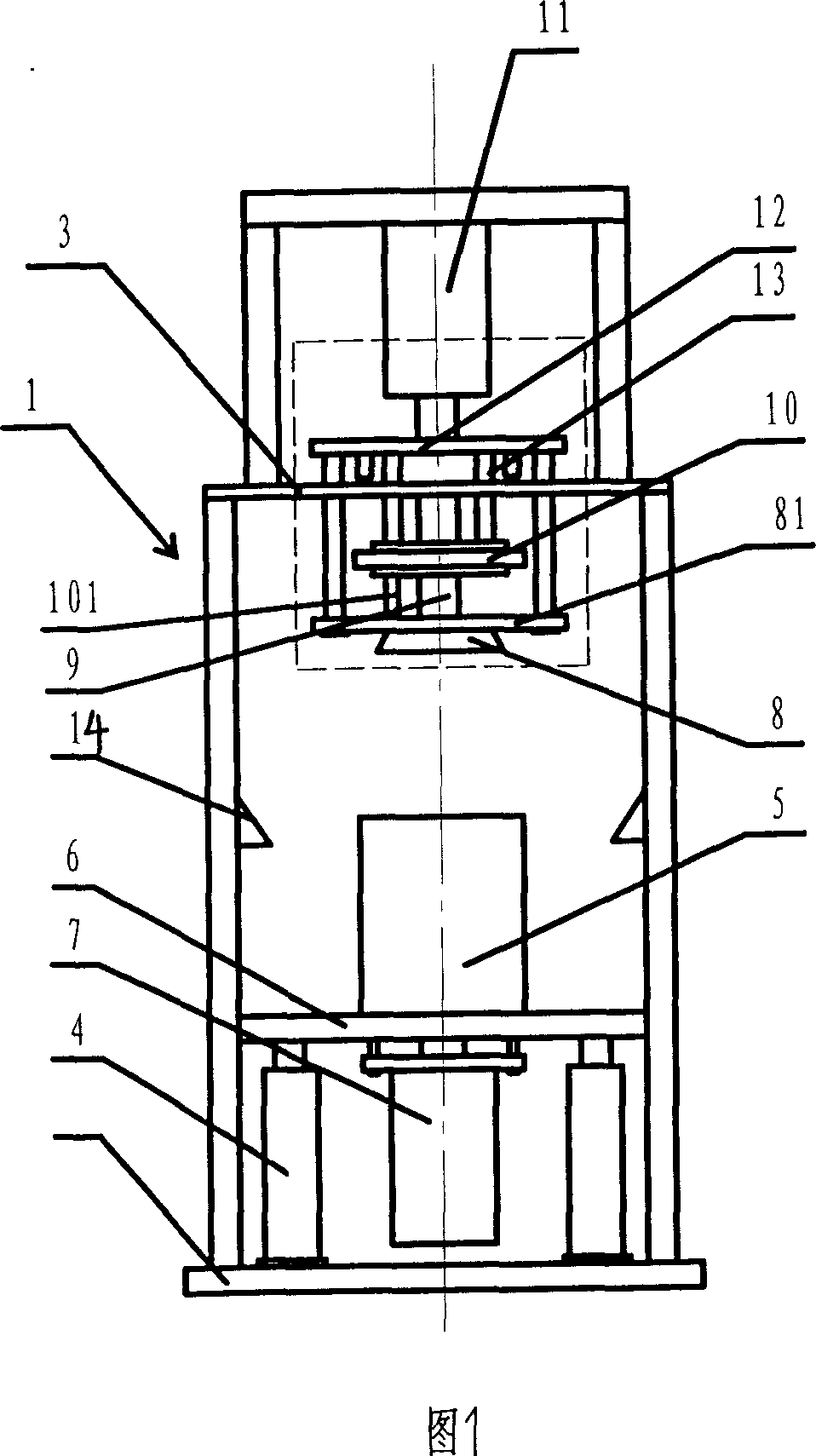

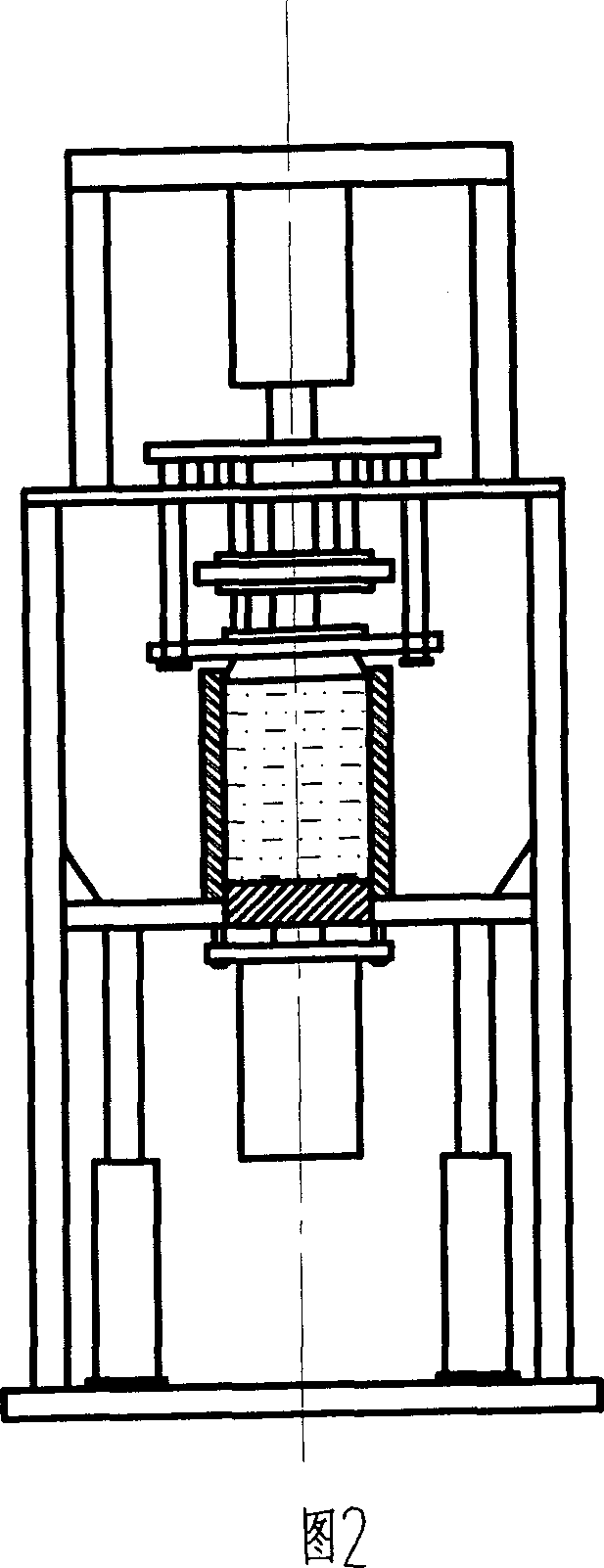

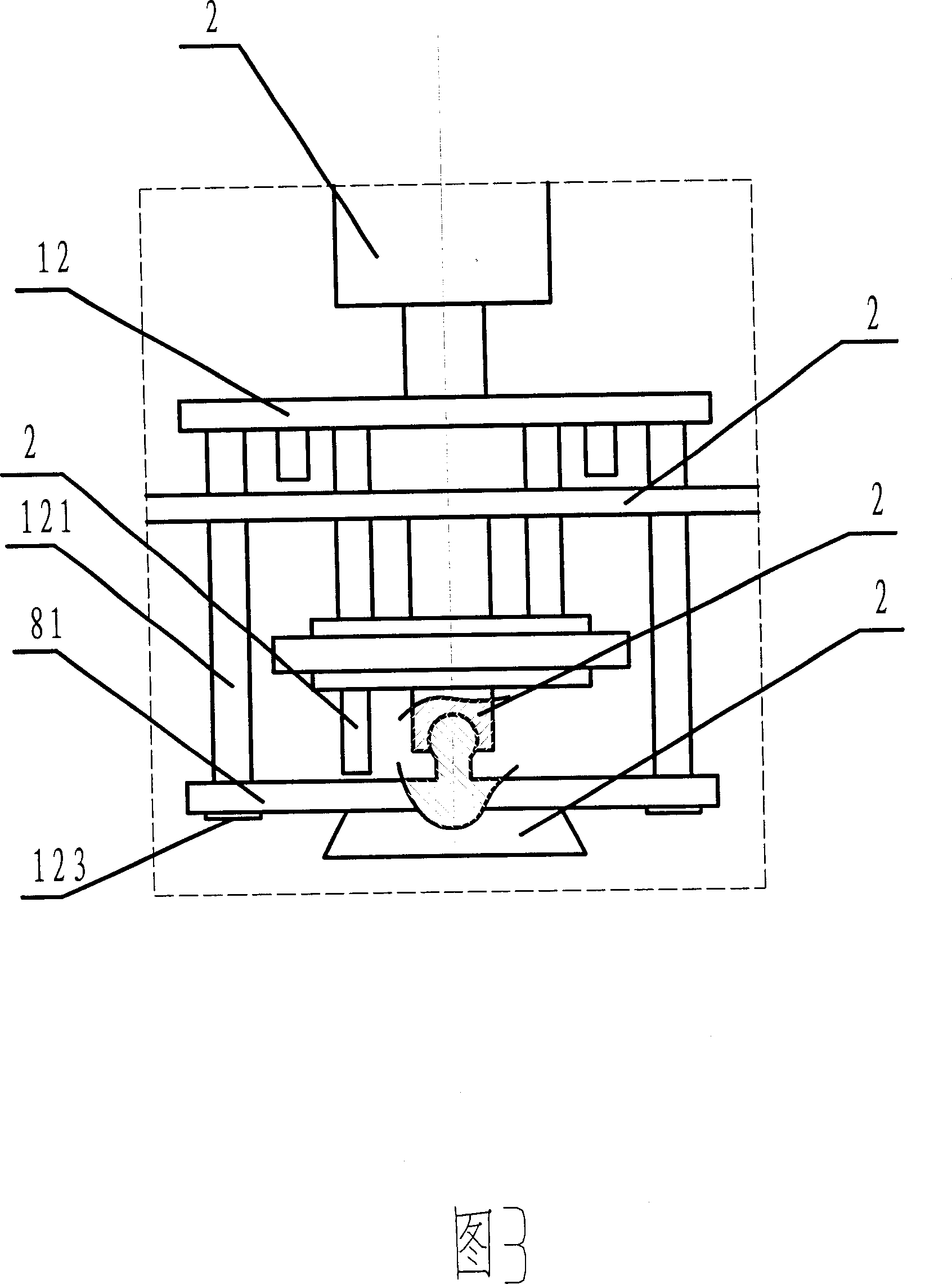

[0014] As shown in Fig. 1, the present invention has a frame 1, and the bottom of frame 1 is provided with base plate 2, and top plate 3 is provided with, and two lifting oil cylinders 4 are arranged symmetrically on both sides on the frame bottom plate 2, and the outlet of lifting oil cylinder 4 The shaft is connected with the support formwork 6 that fixes the test cylinder 5, and the support formwork 6 slides up and down in the frame 1 under the action of the lifting cylinder 4, and the support formwork 6 is provided with a support form that is equivalent to the inner diameter of the test cylinder corresponding to the test cylinder 5 hole, the lower part of the supporting mold hole is equipped with a compacting oil cylinder 7, and the upper part of the frame 1 is provided with an indenter 8 coaxially corresponding to the test cylinder 5, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com