Three dimension outline measuring device and method for mirror article surface

A technology of object surface and three-dimensional contour, which is applied in the field of detection, can solve the problems of complex calculation and large cumulative error, and achieve the effect of simple system structure, reduced measurement cost and improved measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A preferred example of the present invention is described in detail as follows in conjunction with accompanying drawing:

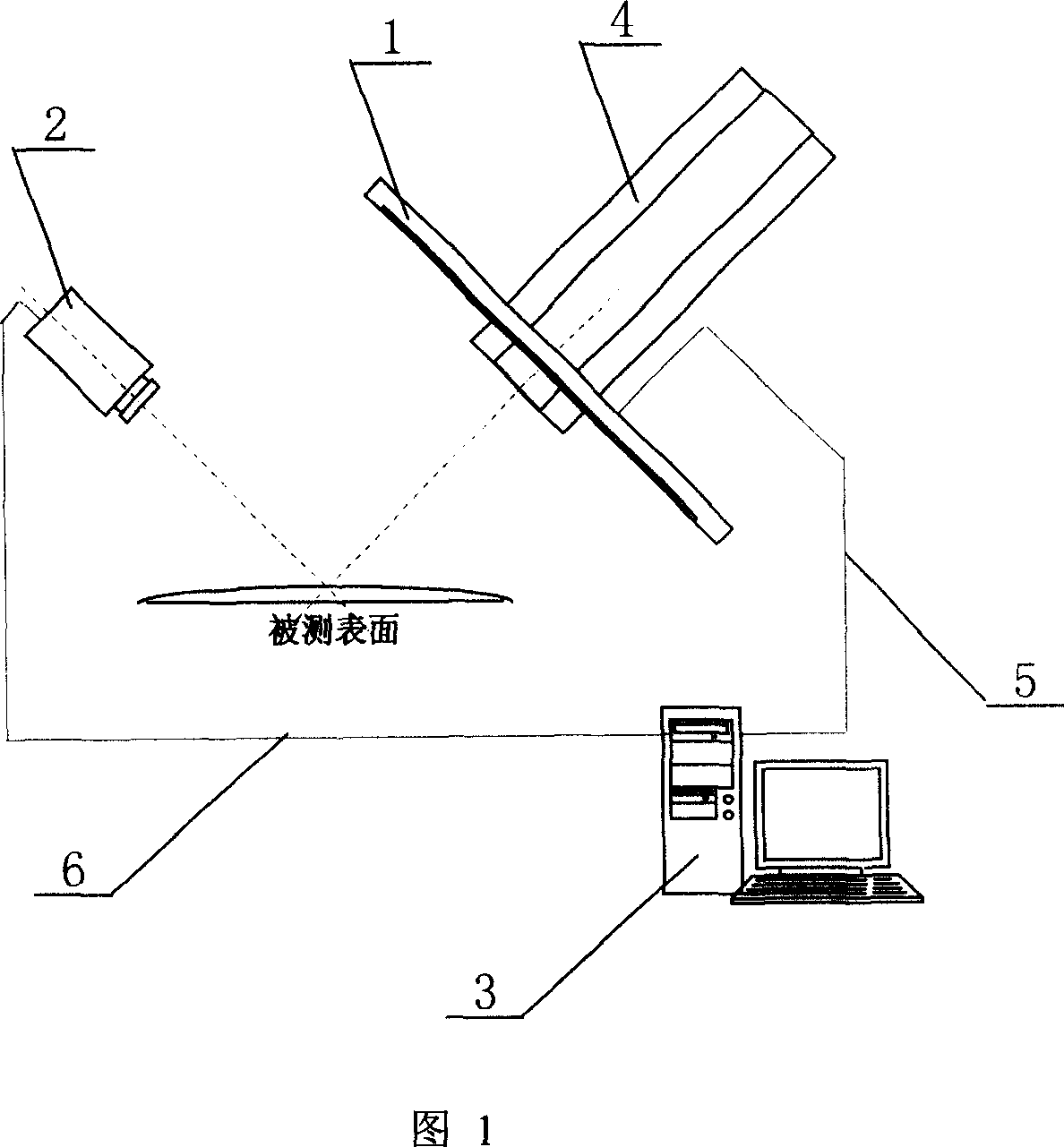

[0022] Referring to Fig. 1, the device for measuring the three-dimensional profile of the surface of a specular object is composed of an LCD flat panel display (1), an industrial camera (2), a computer (3) and a guide rail (4). The LCD flat panel display (1) is fixed on the guide rail (4) and connected with the computer (3) through the data cable (5), which can display the sinusoidal fringe patterns generated by the computer (3), and project these fringe patterns on the measured on the surface of the object. The industrial camera (2) is connected with the computer (3) through the video line (6), and can shoot the projected fringe image on the surface of the measured object, and transmit the fringe image to the computer (3) through the video line (6). The LCD flat panel display (1) is vertically installed on the guide rail (4), and can be translated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com