Control device for sewing machine

A technology for a control device and a sewing machine, which is applied to the control device for a sewing machine, sewing machine components, sewing equipment, etc., can solve problems such as breakage, and achieve the effect of preventing breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] DETAILED DESCRIPTION OF THE INVENTION The present invention will be described in detail below with reference to the drawings showing the best embodiments.

[0050] In the sewing machine control device of the present invention, the prohibition period for prohibiting the operation of the feed switching mechanism for switching the feeding direction of the processed cloth is preset. During the period other than the permit, to prevent the vibrating sewing needle from contacting with the pinhole forming member and being damaged when the feeding direction is switched.

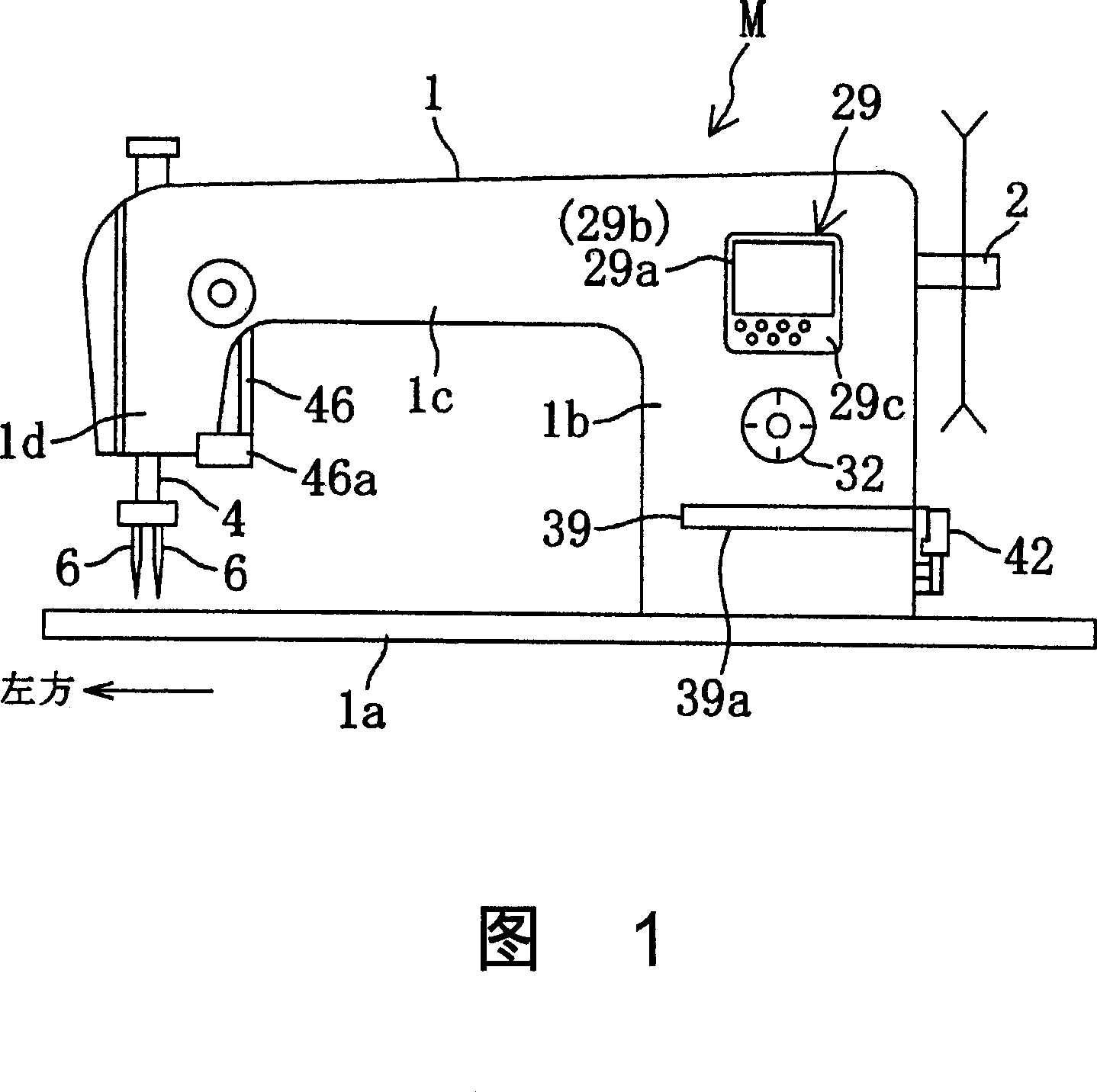

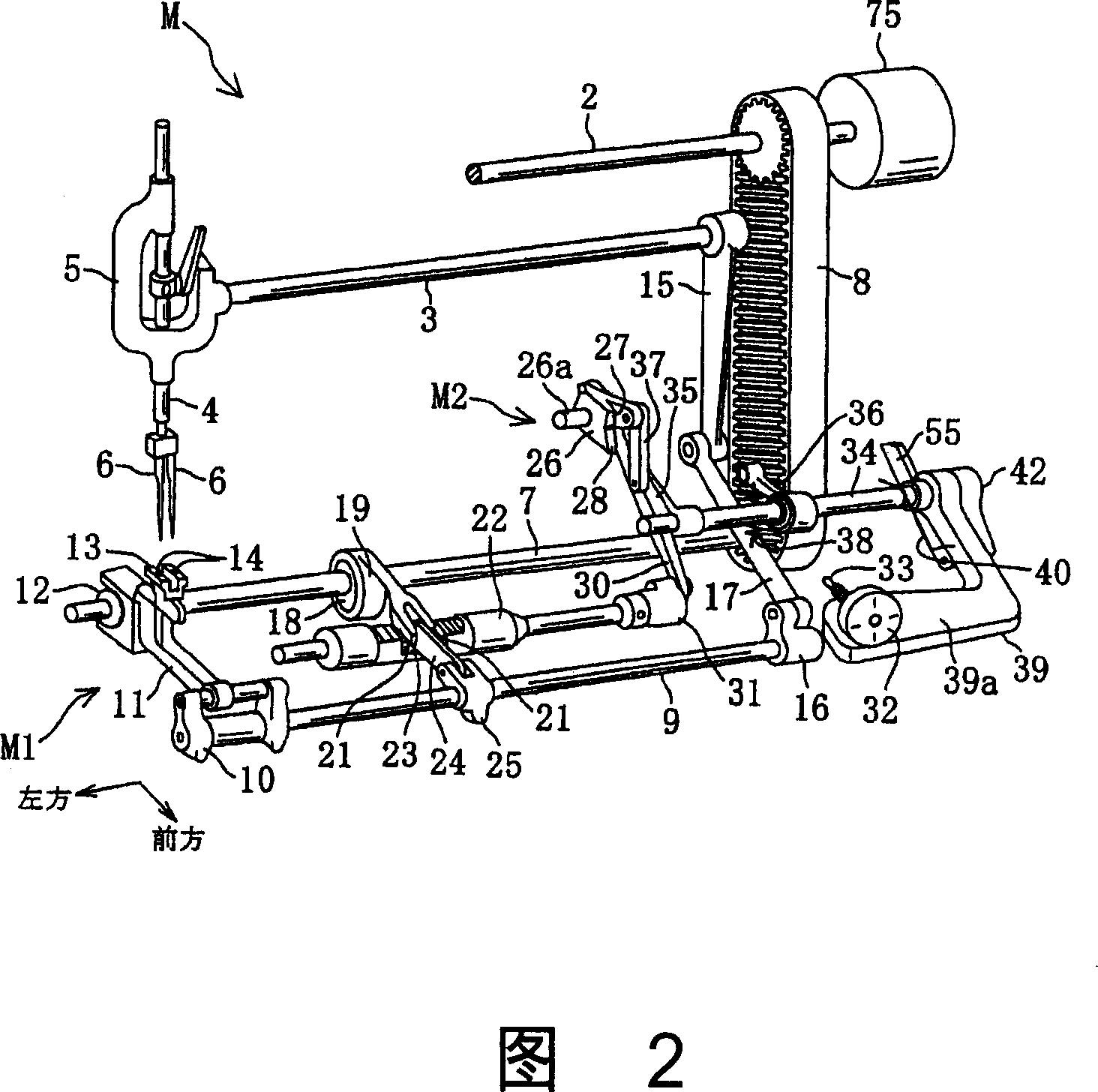

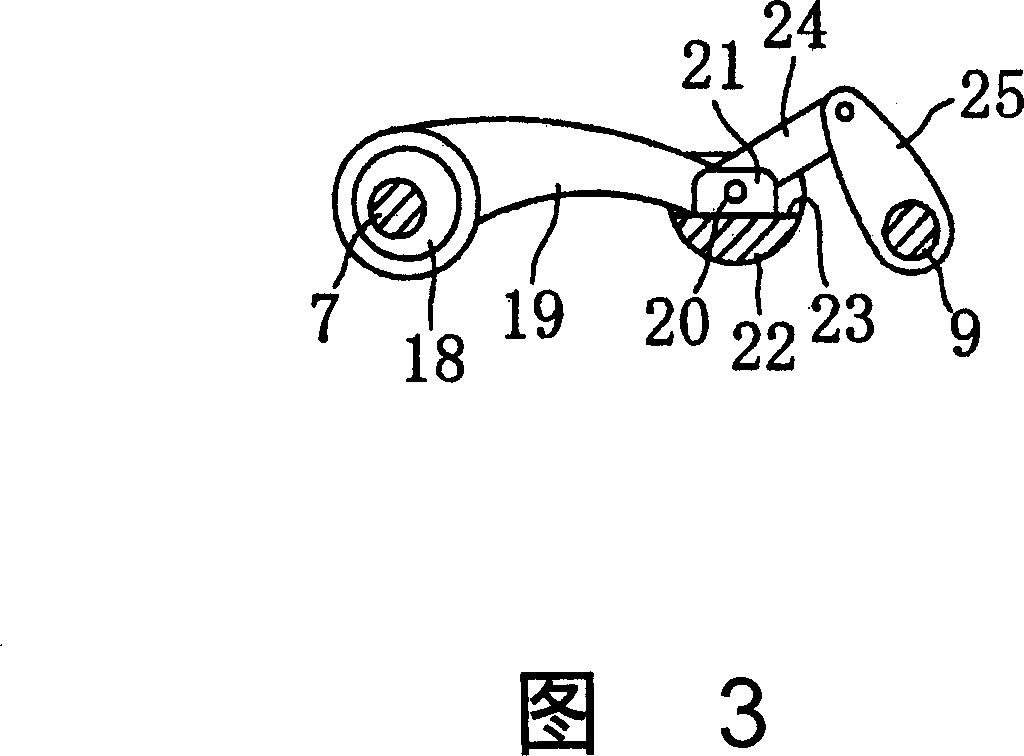

[0051] As shown in Fig. 1 and Fig. 2, the needle-feed sewing machine M includes a machine frame 1 having a bottom plate 1a, a column 1b, and a casing 1c. The sewing machine main shaft 2 and the pendulum shaft 3 are arranged inside the casing 1c, and the machine head 1d is provided at the front end of the casing 1c. The sewing machine main shaft 2 is driven to rotate about its axis by a sewing machine motor 75 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com