Object-size measurement system and method

A measuring and dimensional technology, applied in the field of confocal microscopy devices, can solve the problems of weak signal and inability to reach the photodetector 15

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The aforementioned purpose or features of the present invention will be described in detail according to the accompanying drawings, but it should be understood that the accompanying drawings and the examples given are only for illustration rather than limiting or narrowing the present invention.

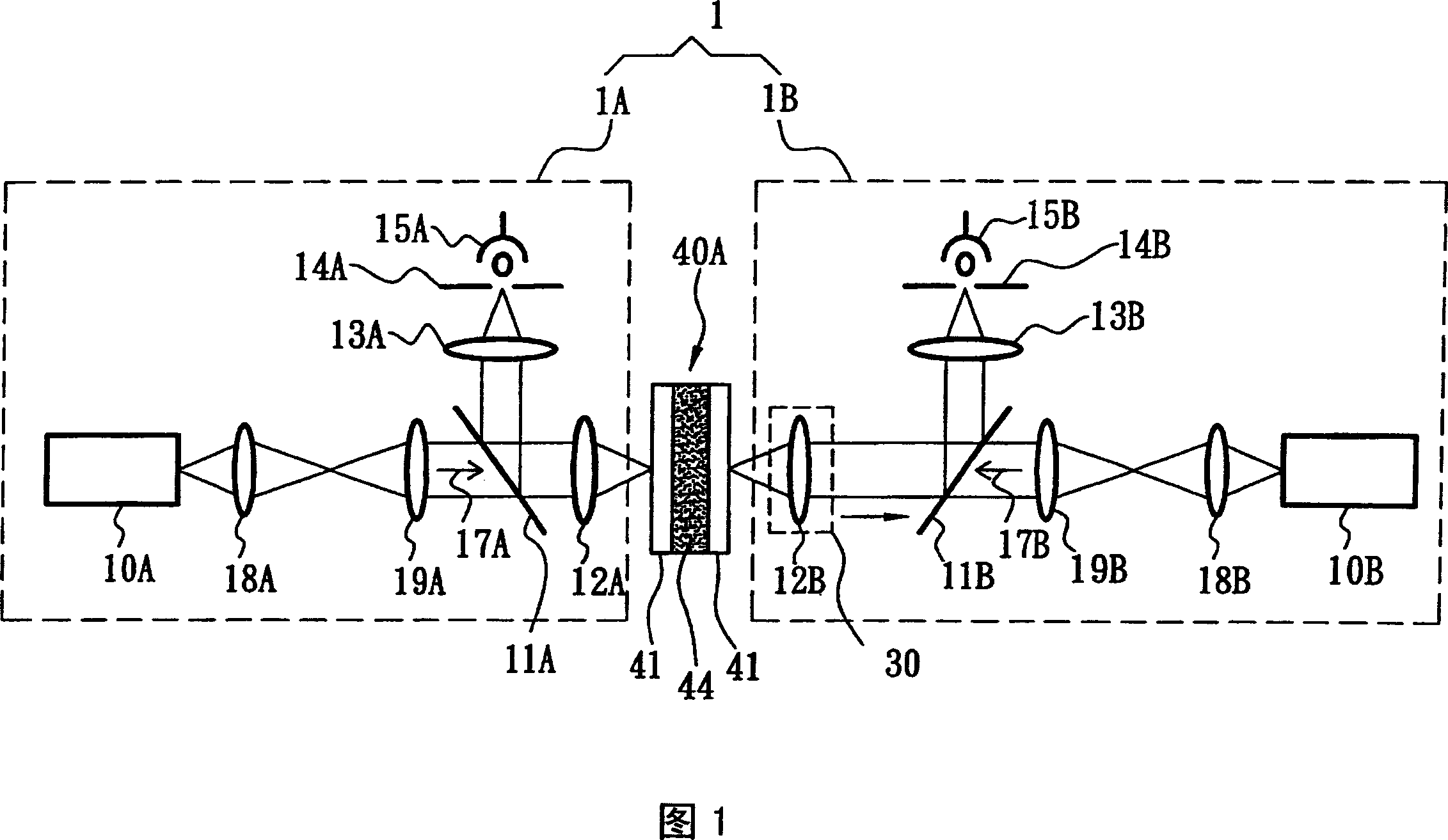

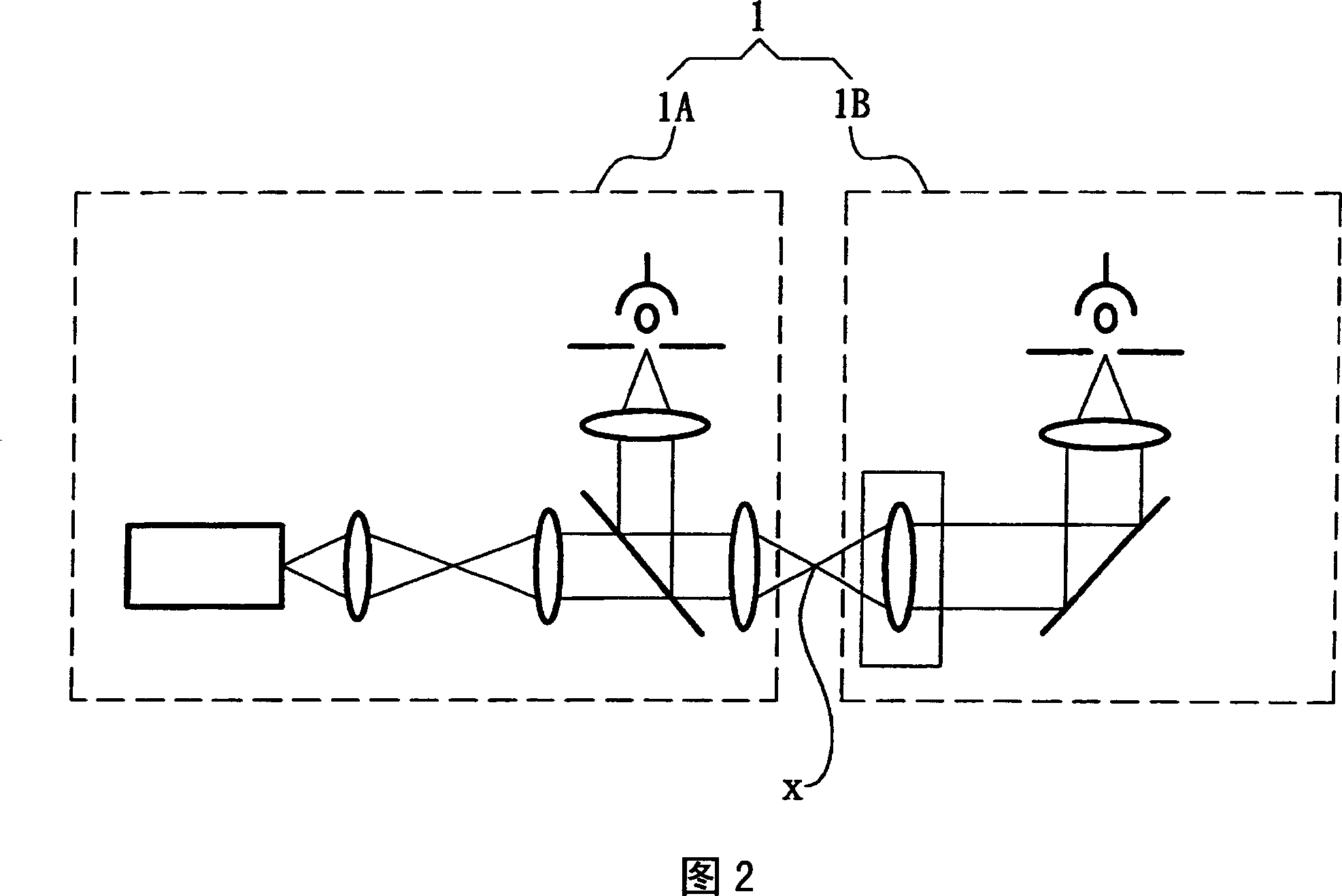

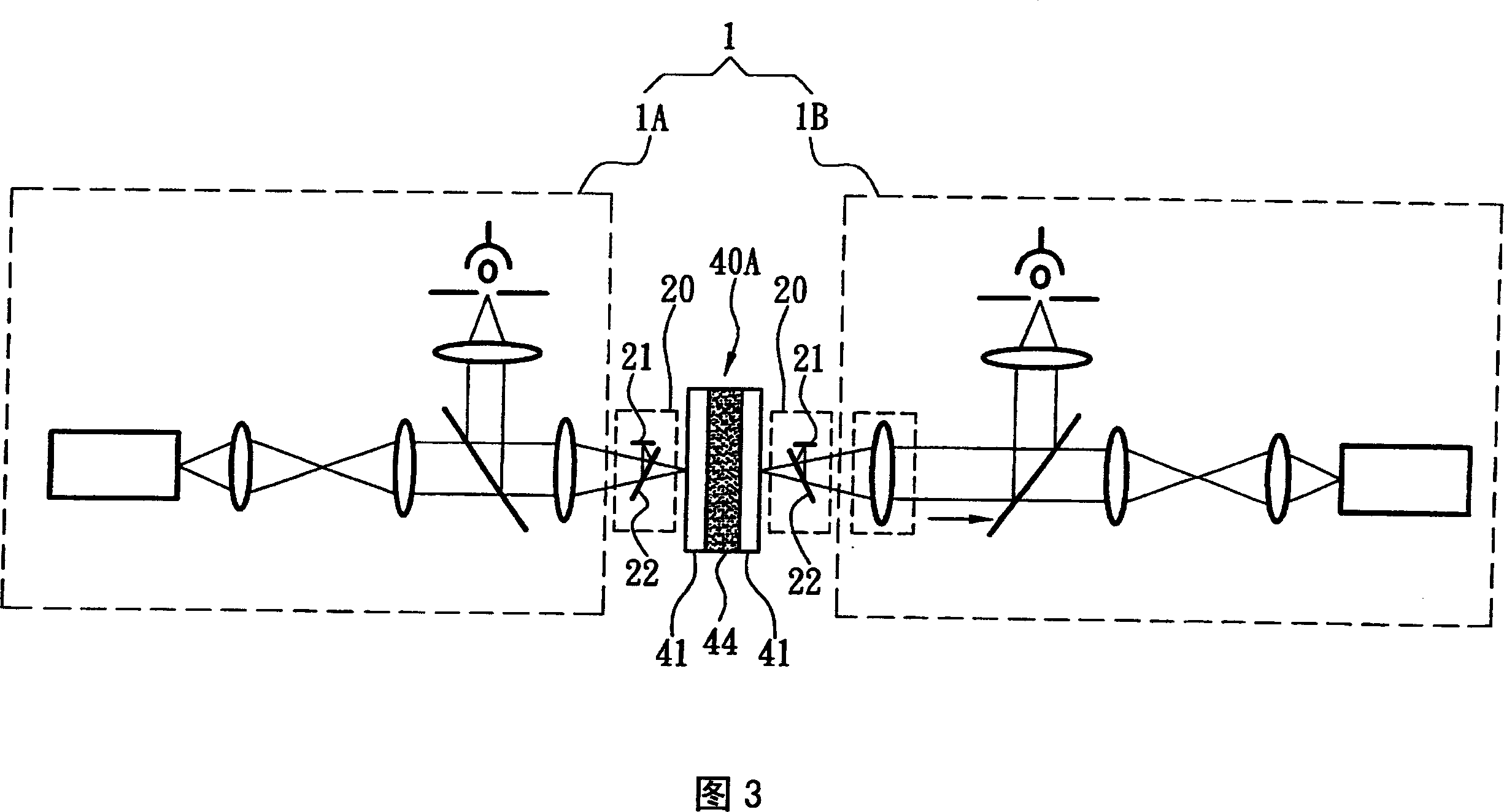

[0056] As shown in Figure 1, the object size measurement system 1 of the present invention includes a first confocal microscopic measurement device 1A, a second confocal microscopic measurement device 1B and a displacement device 30, the first confocal microscopic measurement device 1A and the second confocal microscopic measurement device 1A The confocal microscopic measurement device 1B is respectively arranged on the first and second side end surfaces of the thickness direction of the object to be measured (such as liquid crystal) 40A in a mirroring manner, and each device has a light source 10, a beam splitter as shown in FIG. 11. The structure of the known conventional con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com