Oil container for bearing component of motor

A technology of bearing parts and bearing parts, which is applied to bearing elements, parts of pumping devices for elastic fluids, and bearings of rotary motion, etc., can solve the problems of limit constraints, increase the difficulty of processing, and difficulty in the volume of oil accumulation. , to achieve the effect of preventing leakage, easy processing, and reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

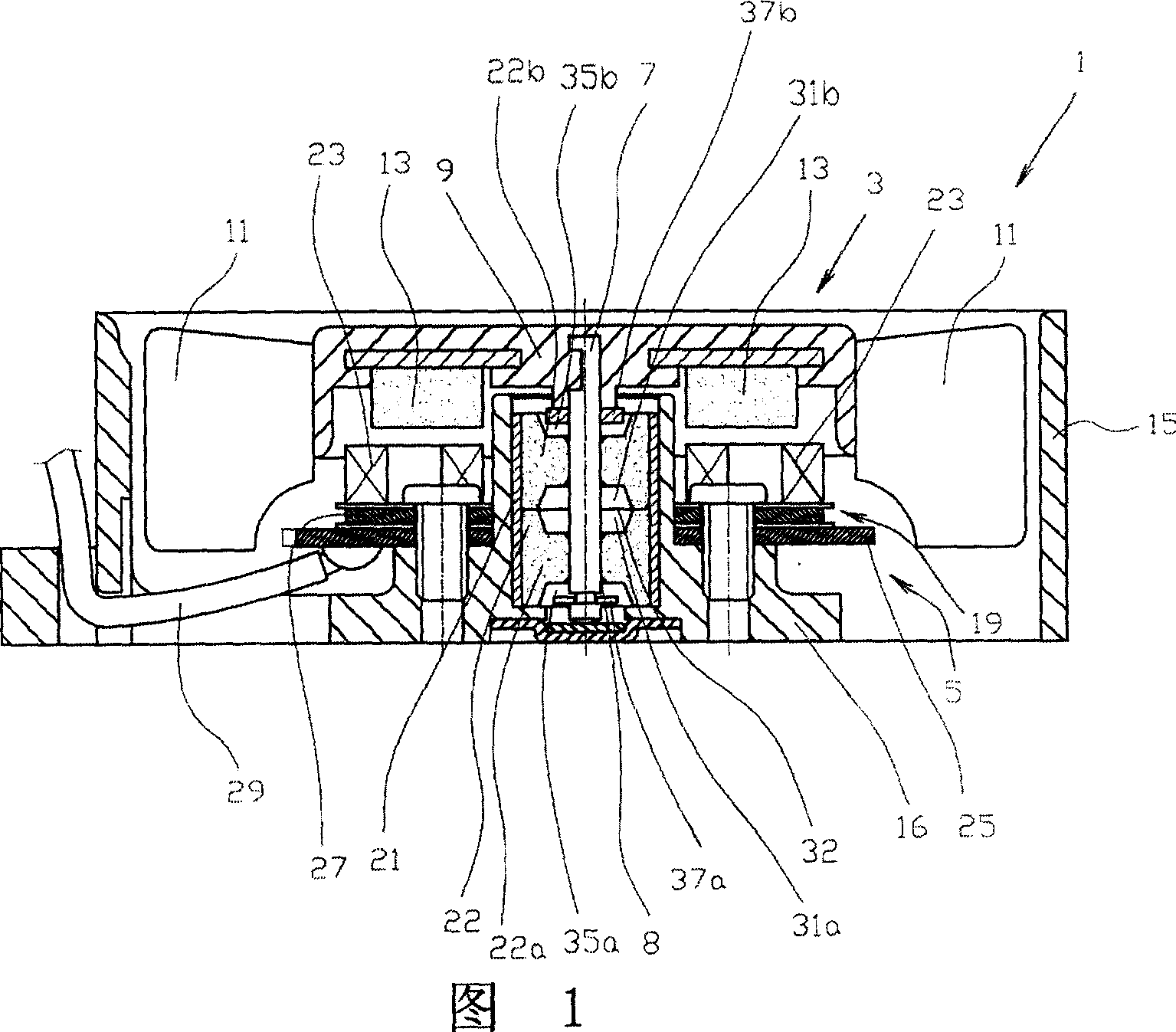

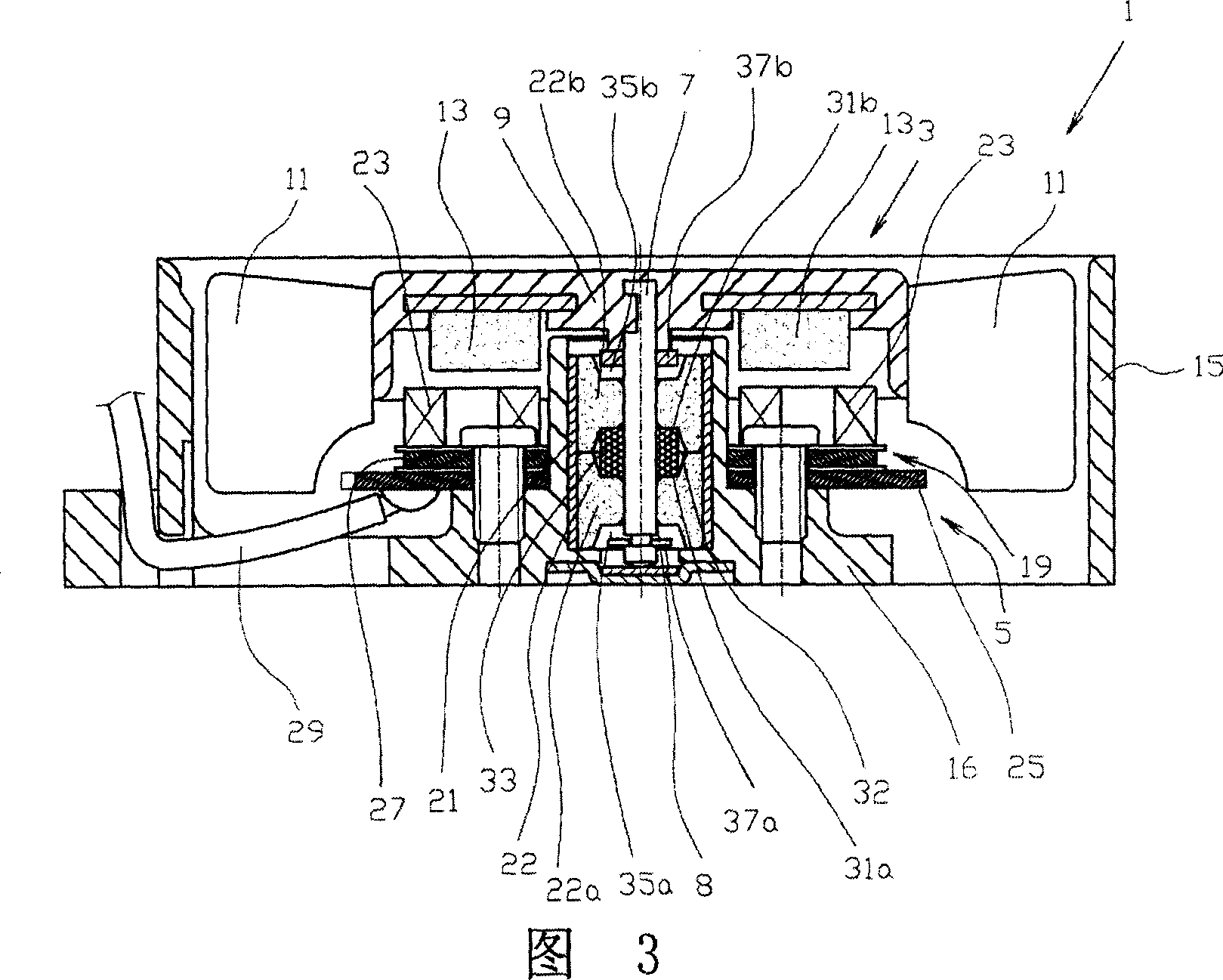

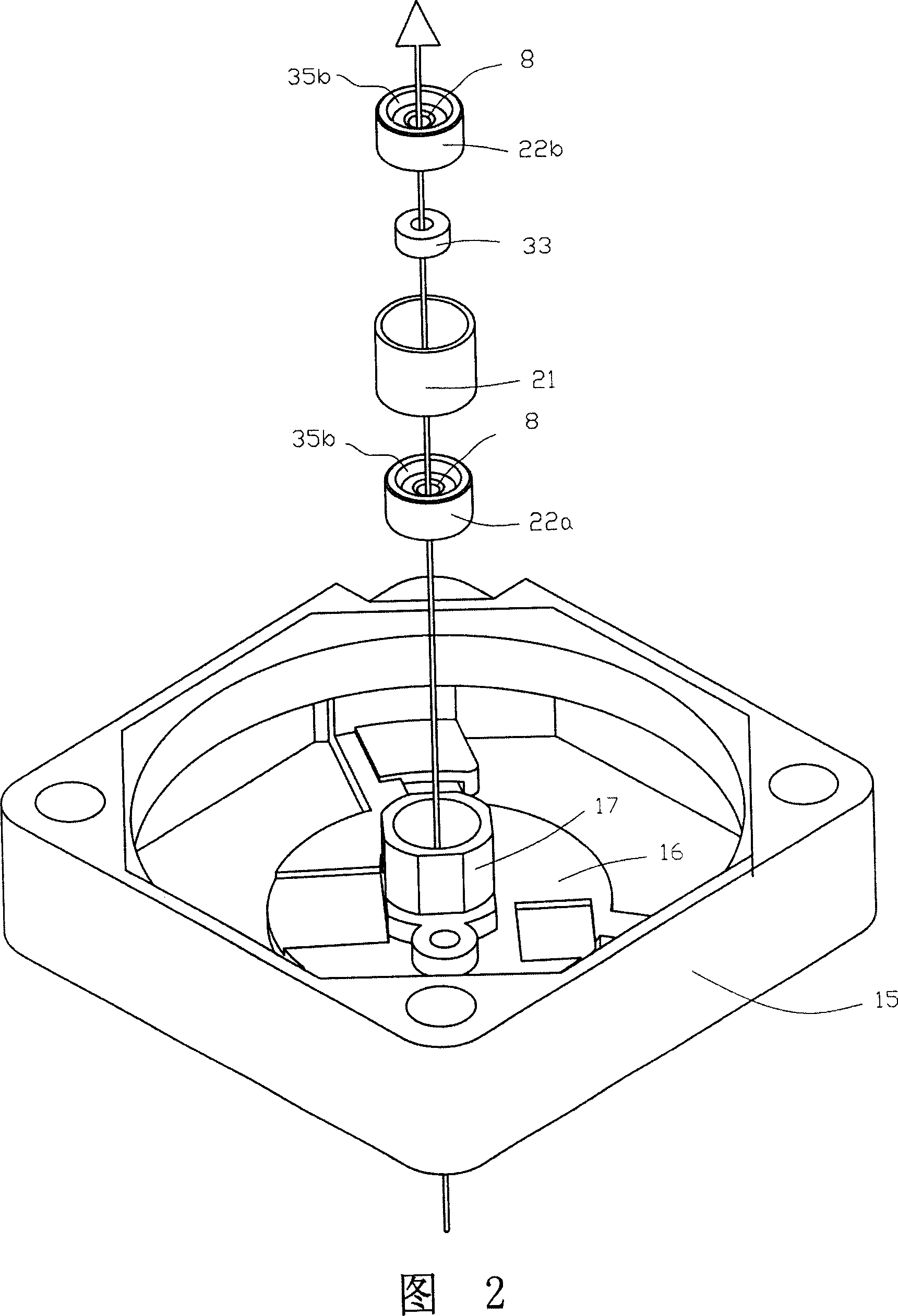

[0029] Please refer to FIG. 1 and FIG. 2 , which are structural schematic diagrams of the first embodiment of the oil storage device for bearing components in the motor of the present invention. In this embodiment, a motor 1 is constituted by a rotor 3 and a stator 5 .

[0030] The rotor 3 includes a rotating hub 9 holding the shaft 7 , a plurality of blades 11 arranged at appropriate intervals on the radially outer peripheral side of the rotating hub 9 , and a magnet 13 provided on the back surface of the rotating hub 9 . The magnets 13 are arranged in concentric circles, and N poles and S poles are arranged to cross each other in the circumferential direction.

[0031] The stator 5 includes a casing 15 , a circular bearing housing 17 formed in the casing 15 , a motor 19 , and a base 16 holding the motor 19 . A circular bearing sleeve 21 made of metal such as iron or brass is inserted into the bearing housing portion 17 , and an oil-impregnated bearing 22 is pressed into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com