Extraction of microbiological polysaccharide-hot gel

A technology of microbial polysaccharide and extraction process, applied in bacteria, fermentation and other directions, can solve problems such as impracticality, and achieve the effects of good performance, cost reduction and ethanol consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

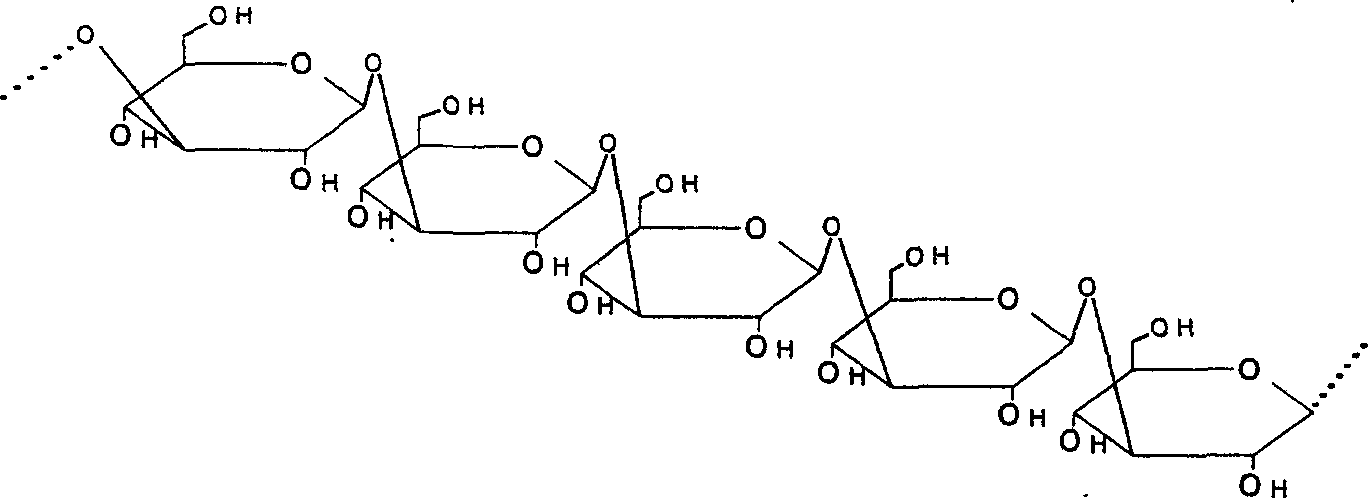

Image

Examples

Embodiment 1

[0011] Embodiment 1. Preparation of thermogel fermented liquid

[0012] Strain Alcaligenes faecalis (Alcaligenes faecalis) WX-C12 was preserved and provided by the Biochemical Engineering Laboratory of the School of Bioengineering, Jiangnan University.

[0013] Fermentation medium (g / L) glucose 50, yeast extract 2, NH 4 Cl 3.6, KH 2 PO 4 2. MgSO 4 ·7H 2 O 0.5, inorganic salt concentrated solution 10mL, pH 7.0 (wherein inorganic salt concentrated solution: FeCl 3 1g, NaCl 1g, CaCl 2 1g, MnCl 2 1 g, 1 L deionized water).

[0014] Utilize 9L fermentation medium, adopt two-stage method (different pH values are controlled during bacterial cell growth and rubber production stage) to carry out fermentation on 15L Biostat C10-3 mechanical stirring tank, the inoculum size is 5%, the stirring speed of the fermenter is 500rpm, and the ventilation volume is 13.5L / min, gauge pressure 0.05MPa, fermentation temperature 30°C. The concentration of NaOH solution to adjust the pH v...

Embodiment 2

[0016] Embodiment 2. Preparation of thermogel fermented liquid

[0017] Bacterial strain and fermentation medium are with embodiment 1. Utilize 18L fermentation medium, inoculum amount 5%, adopt two-stage method (thalline growth and gel production stage control different pH value) to carry out fermentation on the 25L mechanical stirring tank, the stirring speed of fermentation tank is 300rpm, and ventilation rate is 27L / min, The gauge pressure is 0.05MPa, and the fermentation temperature is 30°C. The pH value is controlled at about 7.0 during the growth stage of the bacteria, and adjusted to about 5.6 after 21 hours until the end of fermentation.

[0018] The initial glucose concentration of the fermentation was 50g / L, and the glucose concentration in the fermentation broth dropped below 10g / L after 43 hours of fermentation, and 720g of glucose was added, and the glucose concentration in the fermentation broth dropped to below 10g / L again at 79h, and 720g of glucose was added...

Embodiment 3

[0019] Example 3. Extraction of crude product thermal gel

[0020] Take 2L of fermentation broth, centrifuge at 5000rpm for 15min, and centrifuge and wash the precipitate four times with deionized water at 4°C, dehydrate by centrifugation, then wash with ethanol, dehydrate by centrifuge, dry in vacuum at 37°C, and pulverize to obtain a crude thermogel. Product properties are shown in Table 1:

[0021] fermentation broth

[0022] The extraction process is not dissolved by alkali, and the triple helix conformation of the thermal gel molecule is not destroyed, so the thermal gelation performance is good, but the bacteria are not removed, and the purity is slightly low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com