Finial seat

A technology of top seat and top shaft, applied in the direction of tailstock/top, turning equipment, tool holder accessories, etc., can solve the problems of difficult operation, difficult operation of piezoelectric elements, inability to press the top shaft, etc., to suppress micro-vibration , The effect of maintaining machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

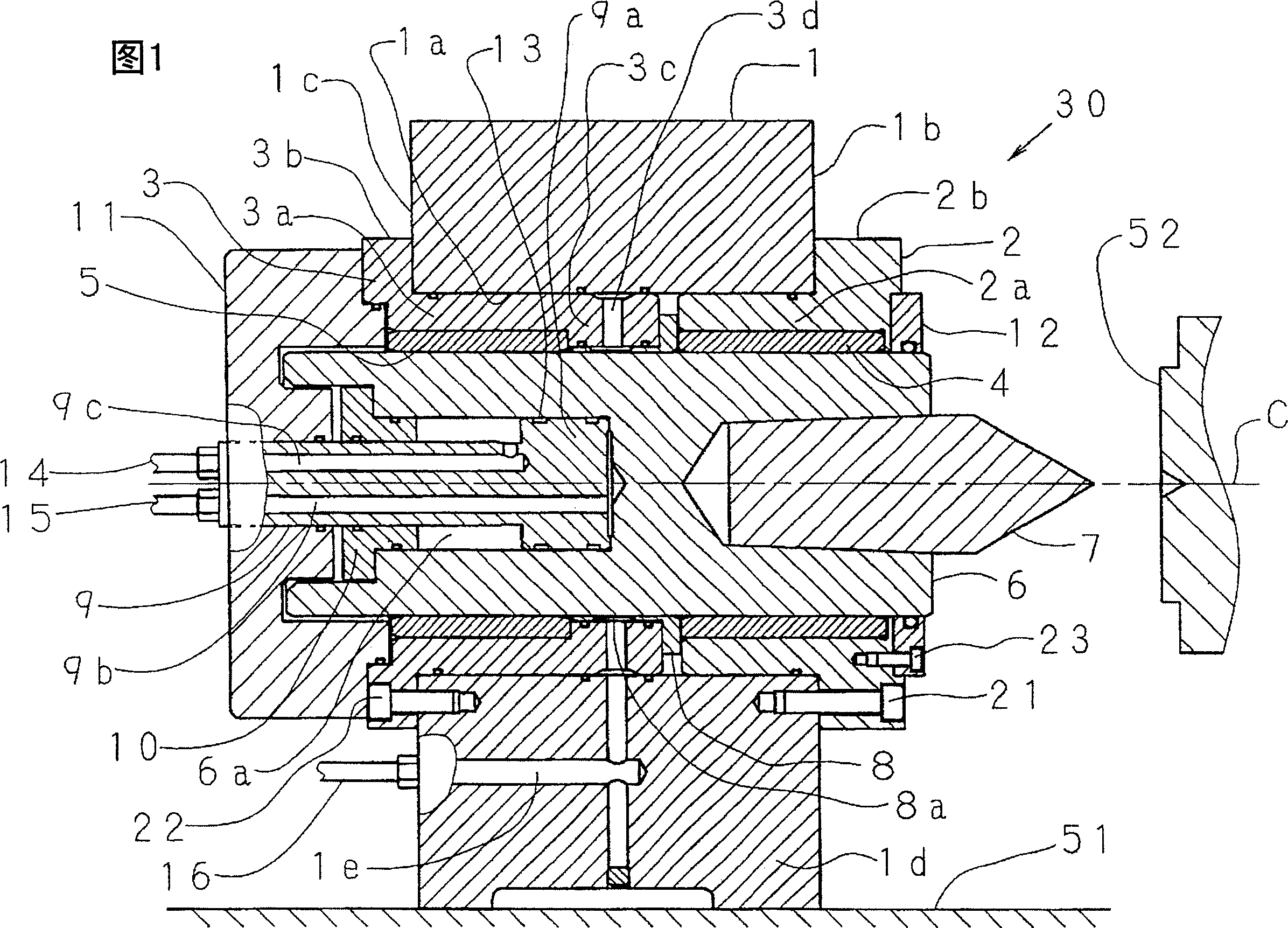

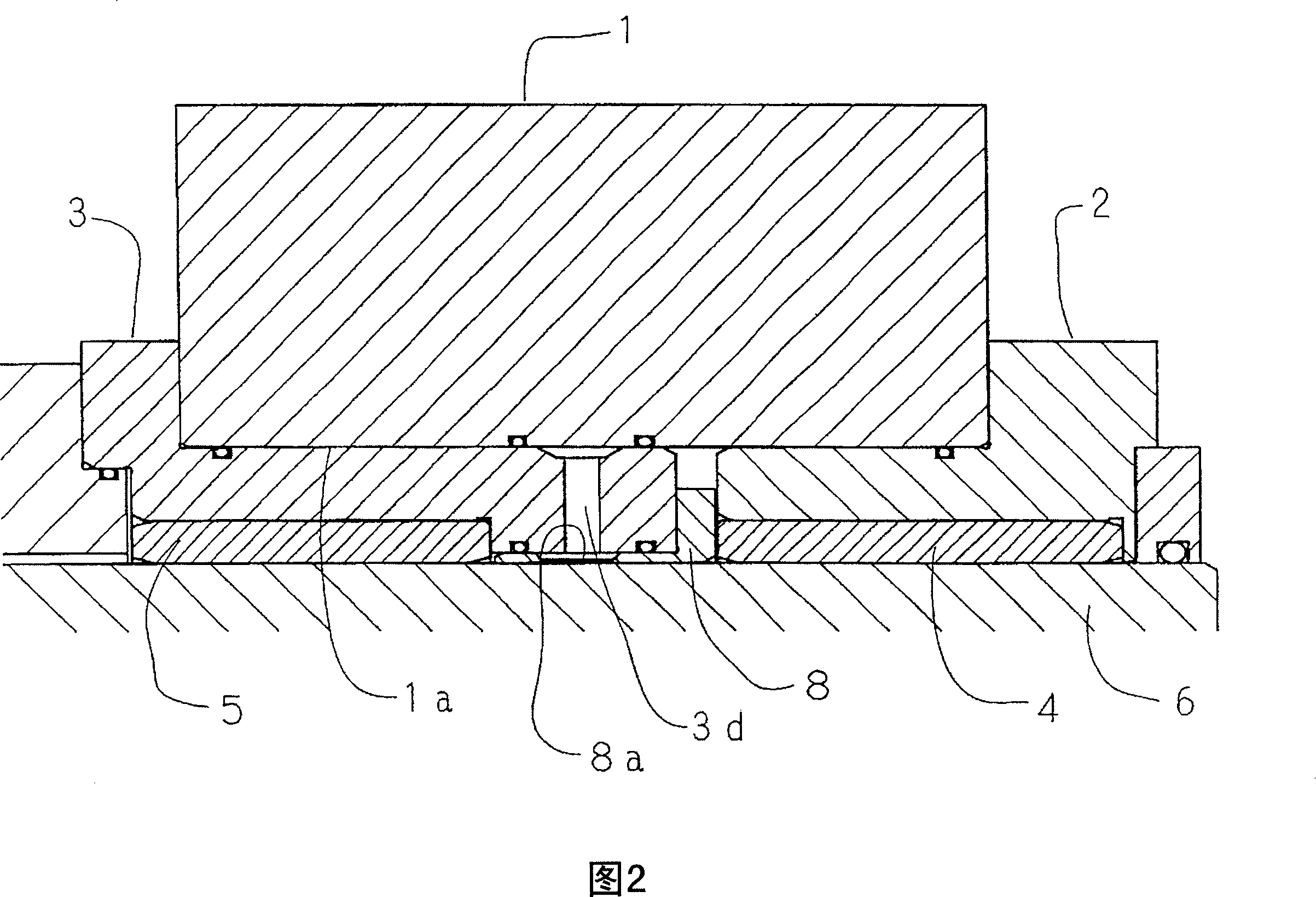

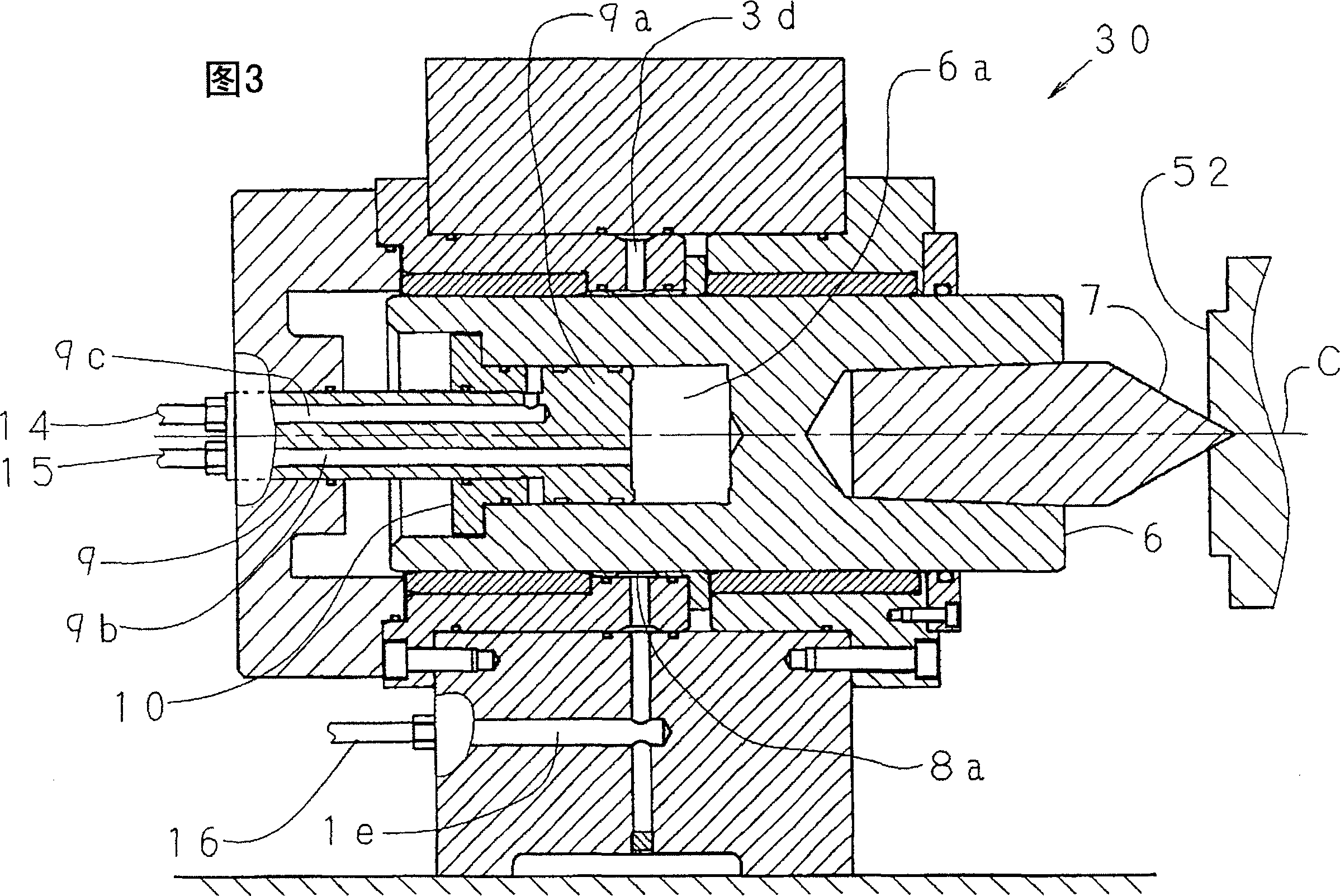

[0023] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. 1 to 3 are cross-sectional views of the center seat 30 according to the first embodiment of the present invention. FIGS. 1 and 3 respectively show the state of the center shaft when it is most retreated and when it is advanced, and FIG. 2 is the main part of FIG. 1 . Partially enlarged image.

[0024] The center seat 30 of this embodiment includes a main body 1, a bearing holder 2, a shaft 6, a center 7, a plunger 9, a plunger guide bush 10, pipes 14, 15, 16, a clamping ring 8, a front side cover 12 and Rear side cover 11.

[0025] The main body 1 has a through hole 1a and a base portion 1d fixed to a slide rail 51 of a machine tool and facing a workpiece 52 held on a machine tool spindle or an index table (not shown). The oil-impregnated bearing 4 of the bearing cage 2 is fitted into the inner peripheral surface of the bearing holding portion 2a, the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com