Mobile electrode of electric dust collector

A technology of electric dust collection and moving electrodes, applied in electrode conveying device, electrode structure, electrostatic separation, etc., can solve the problems of smaller size of dust collecting plate, rising cost and increasing number of parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

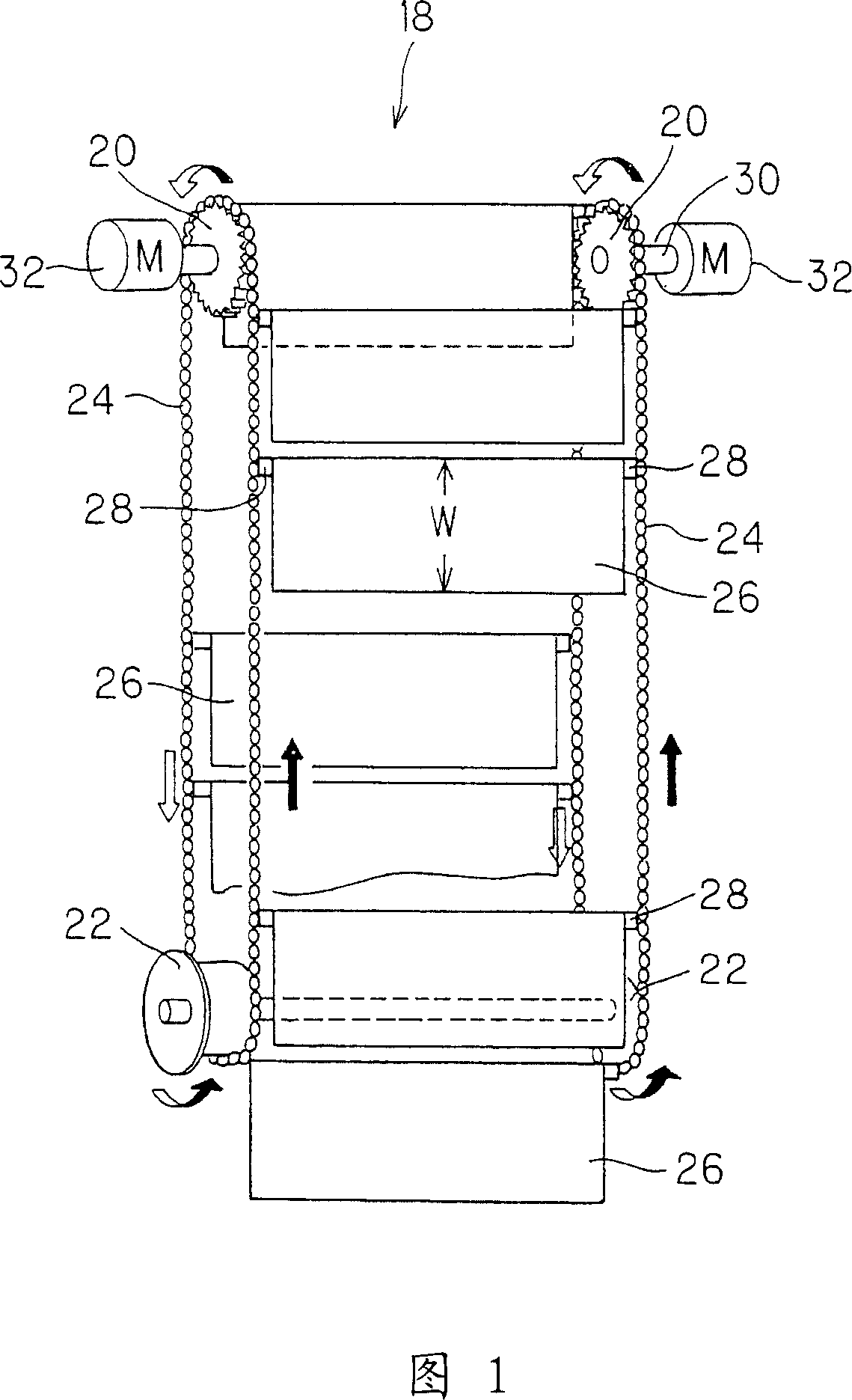

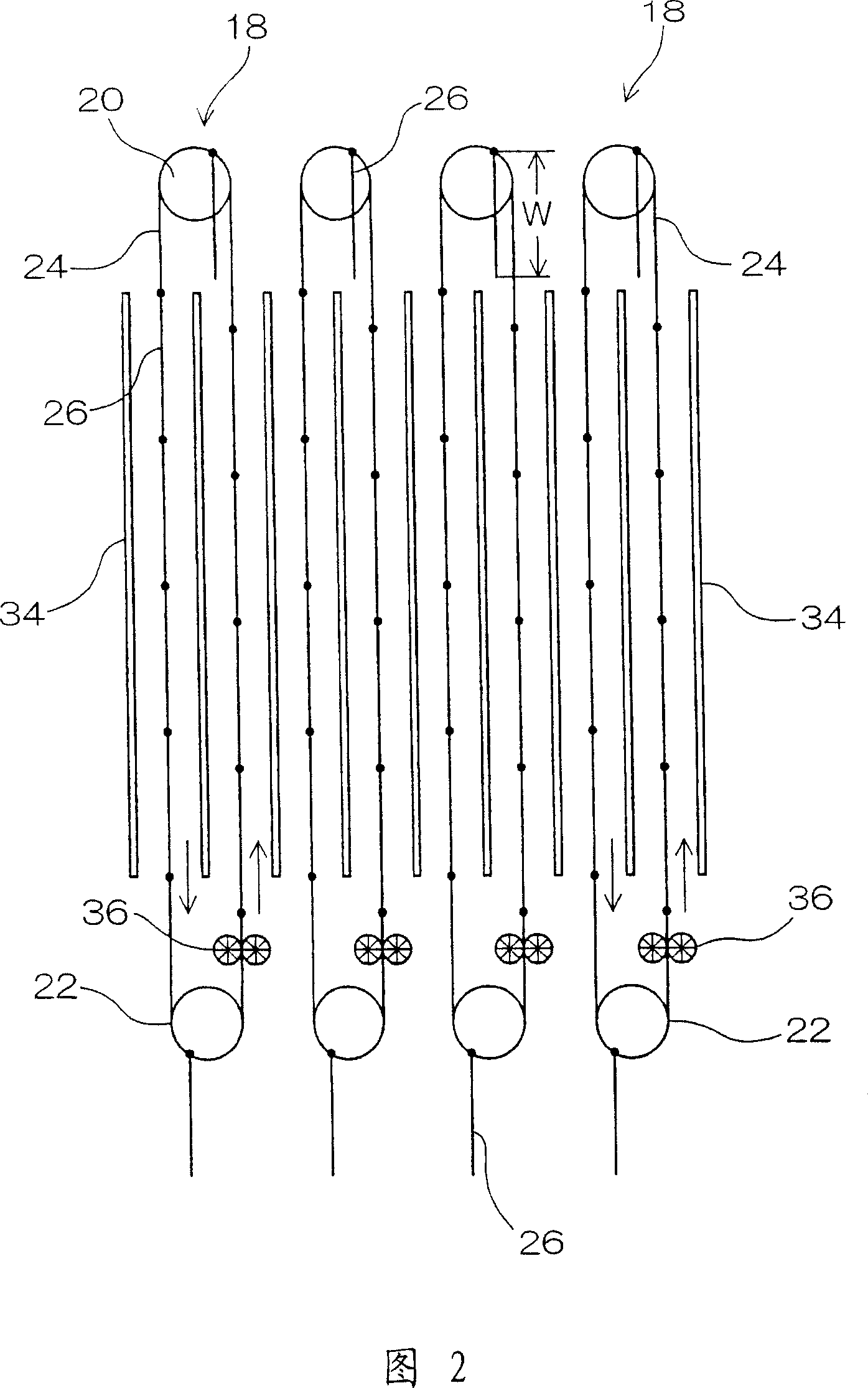

[0029] Fig. 1 is a schematic perspective view showing a first embodiment of a moving electrode of an electric dust collector according to the present invention. A pair of endless chains 24 , 24 is rotatably stretched between a pair of driving wheels 20 , 20 arranged on the upper side and a pair of driven rollers 22 , 22 arranged on the lower side. A plurality of rectangular dust-collecting pole plates 26, 26, ... are connected to a pair of endless chains 24, 24 at their upper end positions so as to be rotatable around a horizontal axis by a connecting portion 28. In addition, for convenience of description, illustration of a part of the dust-collecting plate 26 is omitted in FIG. 1 .

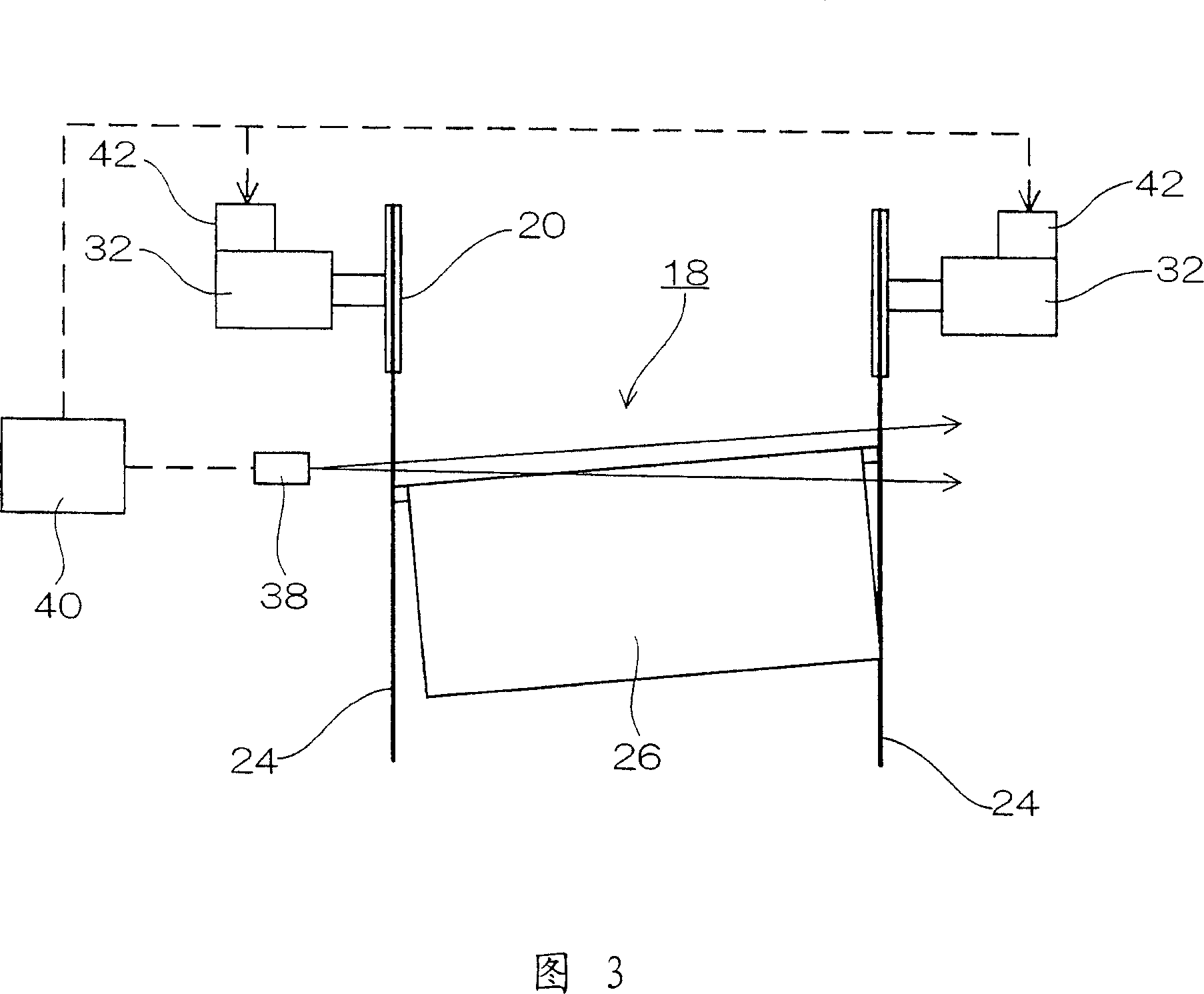

[0030] Each driving wheel 20, 20 is supported by a cantilever shaft 30, 30 from outside the moving area of the dust collecting plate 26, 26, and each is rotationally driven by a driving mechanism 32, 32, respectively. The rotation of the drive wheels 20, 20 is transmitted to a pair of endless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com