Composite white pigment and its preparing method

A white pigment, titanium dioxide technology, applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve limited problems, achieve the effects of reducing costs, improving whiteness and opacity, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

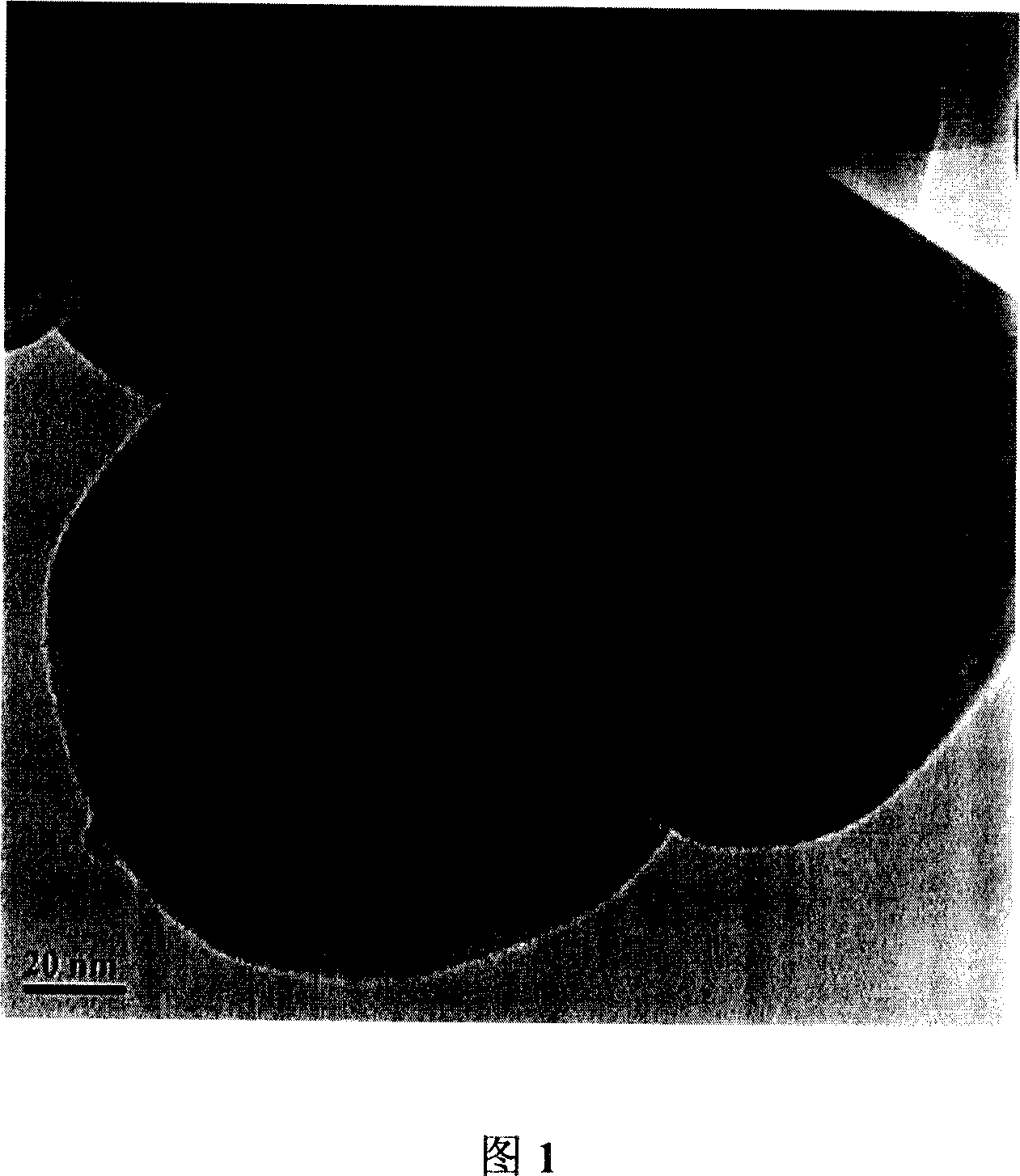

Image

Examples

Embodiment 1

[0029] 1) Add 50kg of anatase titanium dioxide with an average particle size of 0.3μm and 50kg of deionized water into 0.5m 3 In the reactor, prepare a titanium dioxide slurry with a solid content of 50%, add 750g sodium hexametaphosphate, and adjust the pH value to 8 with 200g / L sodium hydroxide solution, and stir;

[0030] 2) Add 82kg of calcium nitrate and 53kg of sodium carbonate to the two feeding tanks, and then add deionized water to the total volume of 0.2m 3 .

[0031] 3) Add calcium nitrate solution and sodium carbonate solution to the reaction kettle simultaneously within 1 hour, stir, so that calcium carbonate particles are generated and deposited on the surface of the titanium dioxide particles to form a firm and uniform shell;

[0032] 4) The resulting suspension is filtered, washed and dried to obtain a composite white pigment containing 50% by weight of titanium dioxide.

[0033] The whiteness of the sample is measured according to GB / T17749-1999, and the dec...

Embodiment 2

[0035] 1) Add 10kg of rutile titanium dioxide with an average particle size of 0.2μm and 80kg of deionized water into 1m 3 In the reaction kettle, prepare titanium dioxide slurry with 20% solid content, add 50g sodium polyacrylate, and adjust the pH value to 11 with 200g / L sodium hydroxide solution, and stir;

[0036] 2) Add 264.5kg of calcium iodide and 125.5kg of potassium carbonate to the two feeding tanks, and then add deionized water to the total volume of 1.6m 3 .

[0037] 3) Add calcium iodide solution and potassium carbonate solution to the reaction kettle simultaneously within 5 hours, keep stirring rapidly, so that calcium carbonate particles are generated and deposited on the surface of titanium dioxide particles to form a firm and uniform shell;

[0038] 4) The resulting suspension is filtered, washed and dried to obtain a composite white pigment containing 10% (by weight) of titanium dioxide.

[0039]The measured whiteness of the obtained product was 92.5%, and ...

Embodiment 3

[0041] 1) Add 90kg of anatase titanium dioxide with an average particle size of 0.5μm and 60kg of deionized water into 0.5m 3 In the reaction kettle, prepare titanium dioxide slurry with 60% solid content, add 125g polyacrylamide, and adjust the pH value to 9.5 with 200g / L sodium hydroxide solution at the same time, and stir;

[0042] 2) Add 7.8kg of calcium fluoride and 7.9kg of ammonium bicarbonate to the two feeding tanks, and then add deionized water to the total volume of 0.3m 3 .

[0043] 3) Add calcium fluoride solution and ammonium bicarbonate solution to the reaction kettle at the same time within 3 hours, keep stirring rapidly, so that calcium carbonate particles are generated and deposited on the surface of titanium dioxide particles to form a firm and uniform shell;

[0044] 4) The resulting suspension is filtered and washed to prepare a composite white pigment slurry with a solid content of 60% and a titanium dioxide content of 90% by weight.

[0045] The measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com