Film hole forming device and method

A film hole and base film technology, applied in the electrical connection formation of printed components, electrical components, printed circuit manufacturing, etc., can solve the problems of difficult removal of residue, slow film hole speed, easy to produce ash, etc., to improve production efficiency and quality The effect of stability, low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

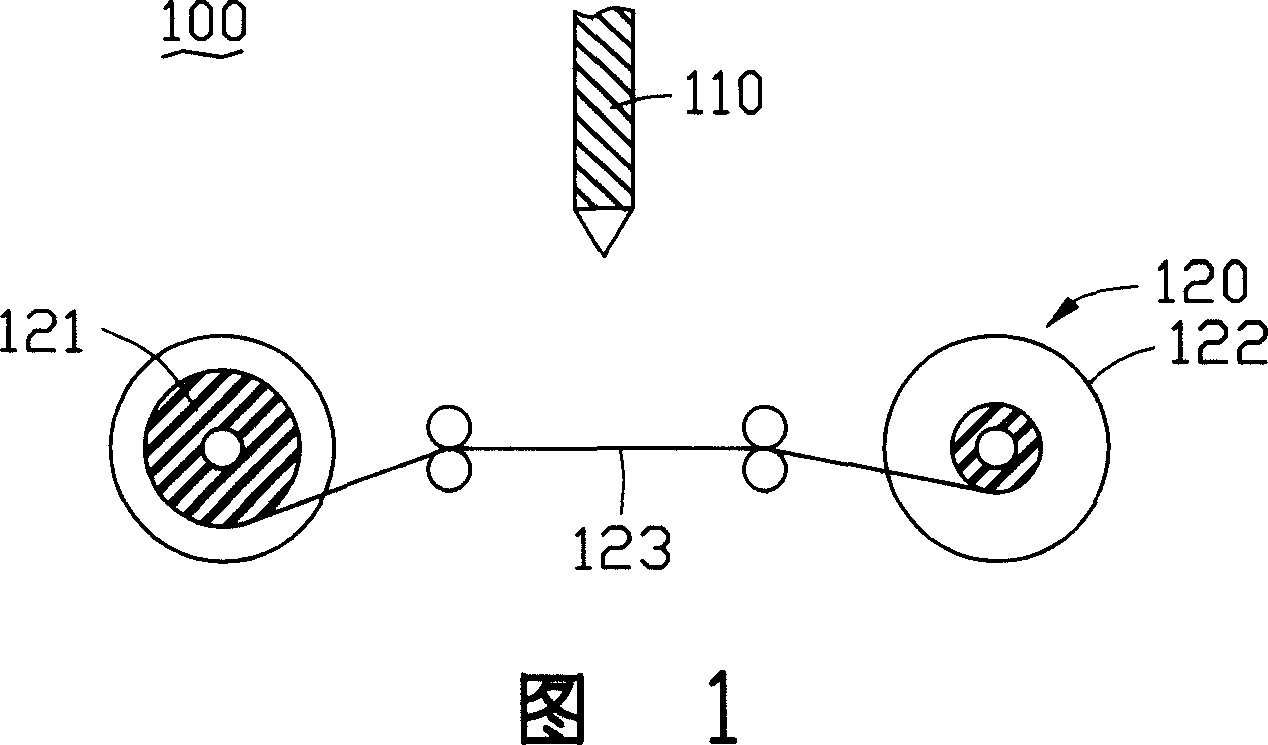

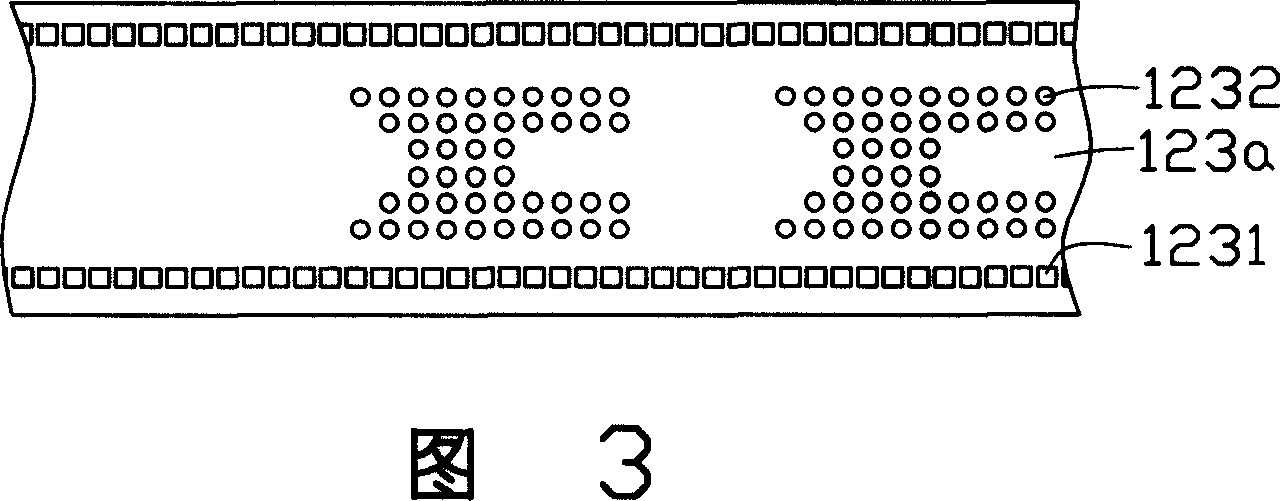

[0037] For the target product of the flexible circuit board, the holes on it are generally composed of copper holes formed on the copper film and film holes formed on the base film. The present invention relates to a device and method for forming film holes on the base film.

[0038] Please refer to FIG. 5 , which is a schematic cross-sectional structure diagram of the first flexible board to be etched in the present invention. The provided flexible board 300 to be etched includes a base film 310 and copper layers 320 on both sides of the base film 310 , and the base film 310 is polyimide or polyester. The surface of the copper layer 320 has a required copper hole 321 with a diameter of 0.05mm˜0.2mm, and the base film 310 is exposed outside at a position corresponding to the copper hole 321 . The bare base film 310 is the position where film holes are to be formed in the present invention, that is to say, the copper holes 321 can play a positioning role.

[0039] The copper h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com