Switching method and mould for crosslinked polyethylene insulated power cable

A cross-linked polyethylene and power cable technology, which is applied in the direction of connecting/terminating cables, etc., can solve the problems of serious economic losses, unqualified withstand voltage and damage of finished or semi-finished products of cross-linked polyethylene insulated power cables. Achieve obvious economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, the length of the cable is not enough, the connection method of the cross-linked polyethylene insulated power cable connecting two cables into one:

[0034] 1) Conductor connection

[0035] The conductors are connected by layered silver soldering, and the solder points of each layer are staggered from each other. When welding, the two ends of the conductor are cooled with cooling water, and the diameter of the welding part is equal to that of the cable conductor;

[0036] 2) Conductor shielding and pre-vulcanization

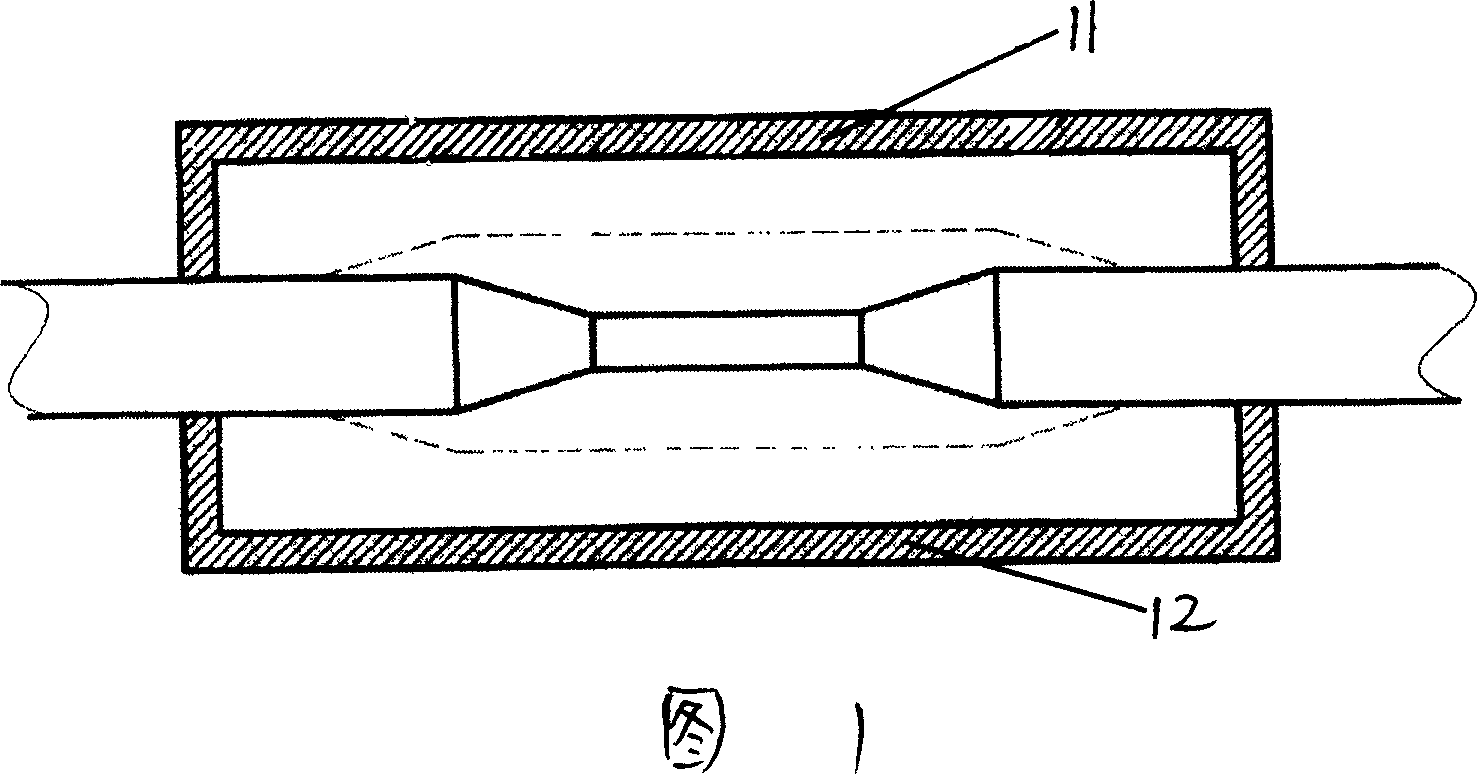

[0037] Borrowing a special mold, the conductor shield vulcanization mold is composed of an upper mold 11 and a lower mold 12 to form a cylinder. The diameter of the round hole formed by the upper and lower mold bodies is slightly larger than the outer diameter of the conductor shield. The operation is as follows:

[0038] a. Clean the surface of the conductor, wrap it on the cable conductor in two layers with a semi-conductive tape, and over...

Embodiment 2

[0056] Embodiment 2, partial splicing, when the cable is bumped or damaged during transportation, there is no need to carry out the overall splicing of the cable, only a few steps in the splicing method are needed.

[0057] Insulation damage, referring to Example 1, starting from the third step, that is, insulation extrusion, and completing the subsequent steps;

[0058] Conductor shielding is damaged. Referring to Example 1, start from the second step, that is, conductor shielding and pre-vulcanization, and complete the subsequent steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com