High-white transparent material formulation and manufacture method of crystal full transparency polishing brick

A technology for polishing tiles and ice crystals, applied in the field of high-white transparent material formulations, can solve the problems of color sensitivity, large deformation, and many pinholes and holes, and achieve high expansion coefficient, stable performance, increased mechanical strength and wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Ice crystal jade transparent material formula:

[0026] (1) Formula composition: white stone powder 10, Chaozhou sand 22, Guangxi sand 18, Hunan stone powder 18.5, white jade powder 10, kaolin 12, Heini 4, M flux 6.5.

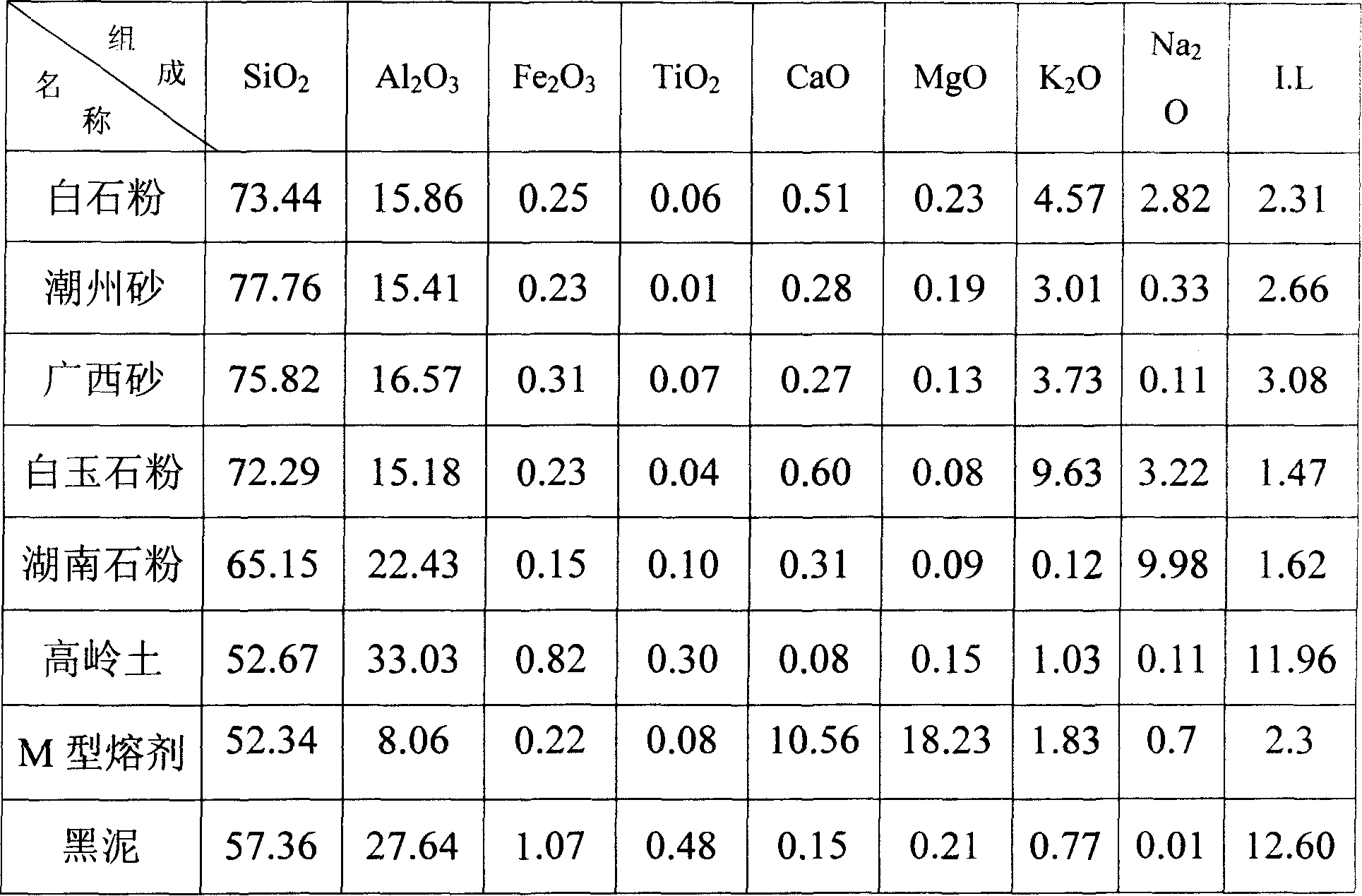

[0027] (2) Chemical composition of raw materials

[0028]

[0029] 2. Mixing process ratio

[0030] Translucent material: transparent material 100% + L-1300 0.16%

[0031] Transparent material: transparent material 20% + super white material 80%

[0032] 3. Molding process

[0033] Hopper number

A

B

C

D

Powder name

Transparent material

High white transparent material

Translucent material

High white transparent material

Broken fineness (200

Item)%

10

15

15

15

Fabric ratio%

15

35

15

35

[0034] Fabric method: secondary fabric, molding times 3.5-4.0 times / min

[0035] Molding pressure 350-380bar

[0036] 4. Dr...

Embodiment approach 2

[0042] 1. Ice crystal jade transparent material formula: same as Example 1

[0043] 2. Color mixing process ratio transparent green material: transparent material 100% + L-1000 0.15% apple green

[0044] 0.13% transparent white material: transparent 20% + super white 80%

[0045] 3. Molding process

[0046] Hopper number

A

B

C

D

Powder name

Transparent material

High white transparent material

Transparent green material

High white transparent material

Broken fineness (200

Item)%

10

15

15

15

Fabric ratio%

15

35

15

35

[0047] Other molding parameters are the same as the first embodiment

[0048] 4. Drying and sintering process: the same as in Example 1; 5. Firing parameters: the same as in Example 1;

Embodiment approach 3

[0050] 1. Ice crystal jade transparent material formula: same as embodiment 1

[0051] 2. Proportioning of color mixing process Yellow transparent material: transparent material + L1000 0.35%, praseodymium 0.12%;

[0052] Transparent material: transparent material 20% + super white material 80%

[0053] 3. Molding process

[0054] Hopper number

A

B

C

D

Powder name

Transparent material

High white transparent material

Yellow through

High white transparent material

Broken fineness (200

Item)%

10

15

15

15

Fabric ratio%

15

35

15

35

[0055] Other molding parameters are the same as the first embodiment

[0056] 4. Drying and sintering process: the same as in Example 1; 5. sintering parameters: the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com