Vertical axis type grinding head

A vertical shaft type, grinding head technology, applied in the direction of grinding machine parts, grinding/polishing equipment, metal processing equipment, etc., to achieve the effect of high precision, enhanced contact stiffness, and firm mutual positional relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be specifically described below in conjunction with specific embodiments.

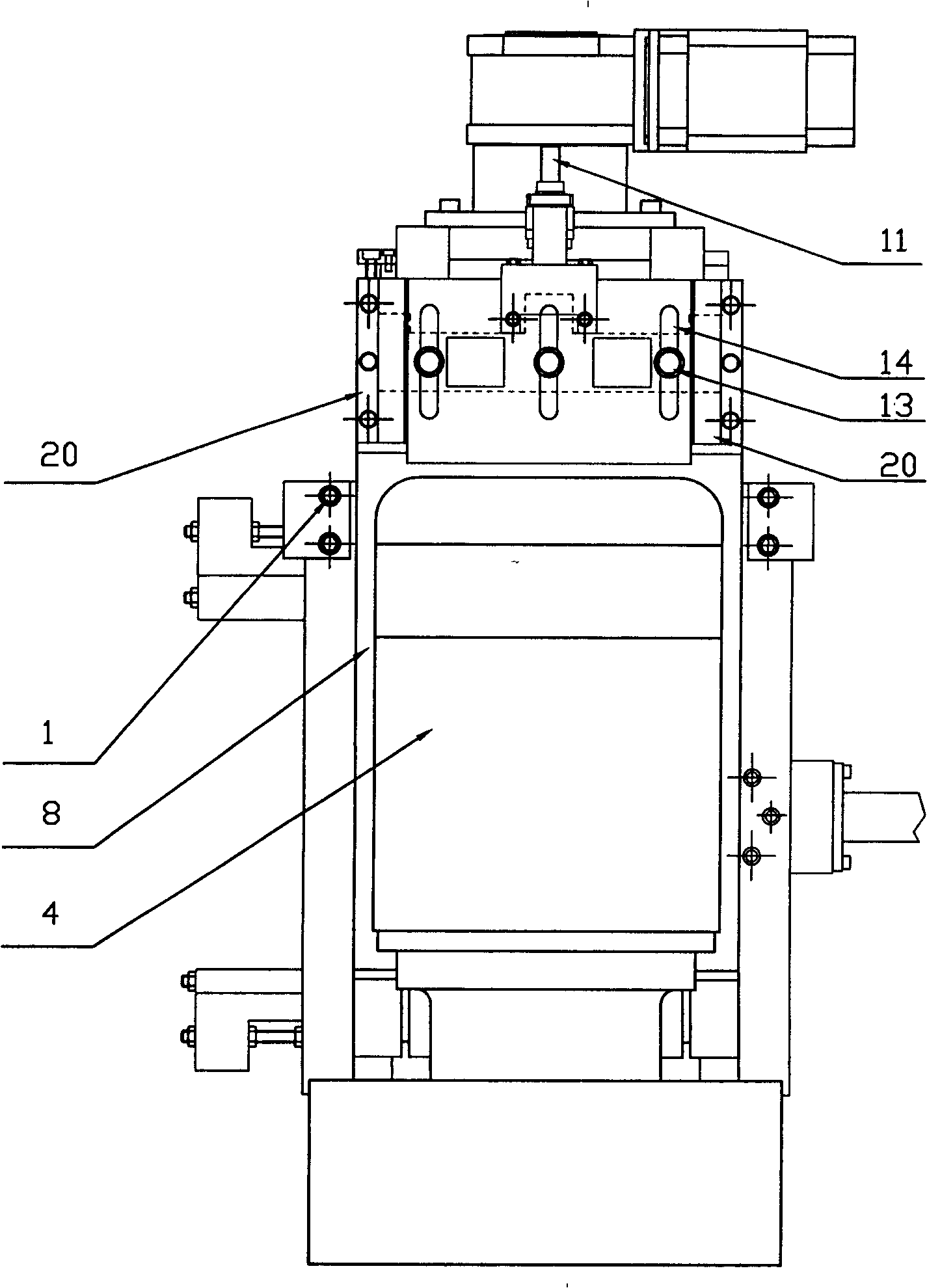

[0034] Such as Figure 1 to Figure 6 As shown, the vertical shaft grinding head includes a carriage 1, a slide table 2, and a vertical shaft motor 4 with a grinding disc 3 installed at the bottom. Slide table 2 is conventional slide table, and it comprises ram 5, transmission mechanism 6, slide seat 7. The carriage 1 is connected with the ram 5 of the slide table 2 through a rotation adjustment mechanism. The lower part of the sliding seat 7 is rotatably connected with the lower part of the rocking plate 8 through a rotating shaft 19 . The motor 4 is connected with the rocking plate 8 . An adjustable device is connected between the upper part of the sliding seat 7 and the upper part of the rocking plate 8, and the adjustable device can adjust the rotation of the rocking plate 8 to a certain angle relative to the sliding seat 7. The adjustable device is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com