Gas lower exhaustion type whirlwind air-solid separator

A solid separation and cyclone technology, which is used in cyclone devices, devices whose axial directions of cyclones can be reversed, lighting and heating equipment, etc. Unreasonable design, influence of fly ash separation efficiency, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

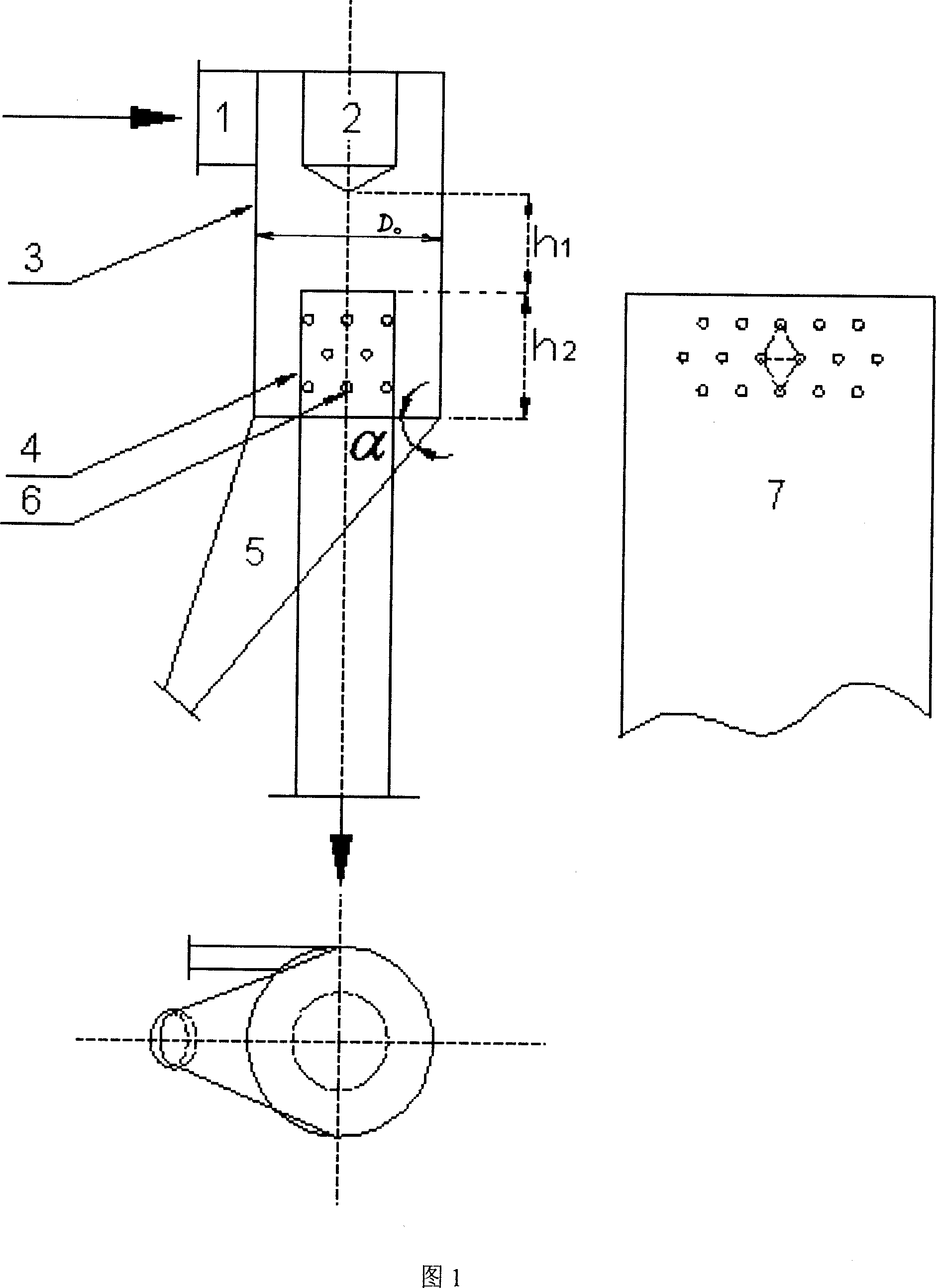

[0021] The structure of the lower exhaust type cyclone gas-solid separator of the present invention is shown in Fig. 1, and it comprises inlet pipe 1, guide bar 2, cylinder body 3, exhaust pipe 4 and inclined ash bucket 5, and exhaust pipe 4 extends Into the cylinder 3, the height of the intrusion into the cylinder is h2, and there are small holes 6 on the exhaust pipe section extending into the cylinder, the small holes are evenly arranged in an equilateral triangle, and the diameter of the small holes is 7 mm , the sum of the areas of all small holes is equal to the area of the exhaust pipe inlet. The inner diameter of the cylinder is D 0 , the width of the inlet pipe is 0.30D 0 , with a height of 0.6D 0 , the diameter of the guide rod and the exhaust pipe are both 0.5D 0 , the distance between the guide rod and the top of the exhaust pipe is h2, and the inclination angle α of the inclined ash hopper is 50 degrees.

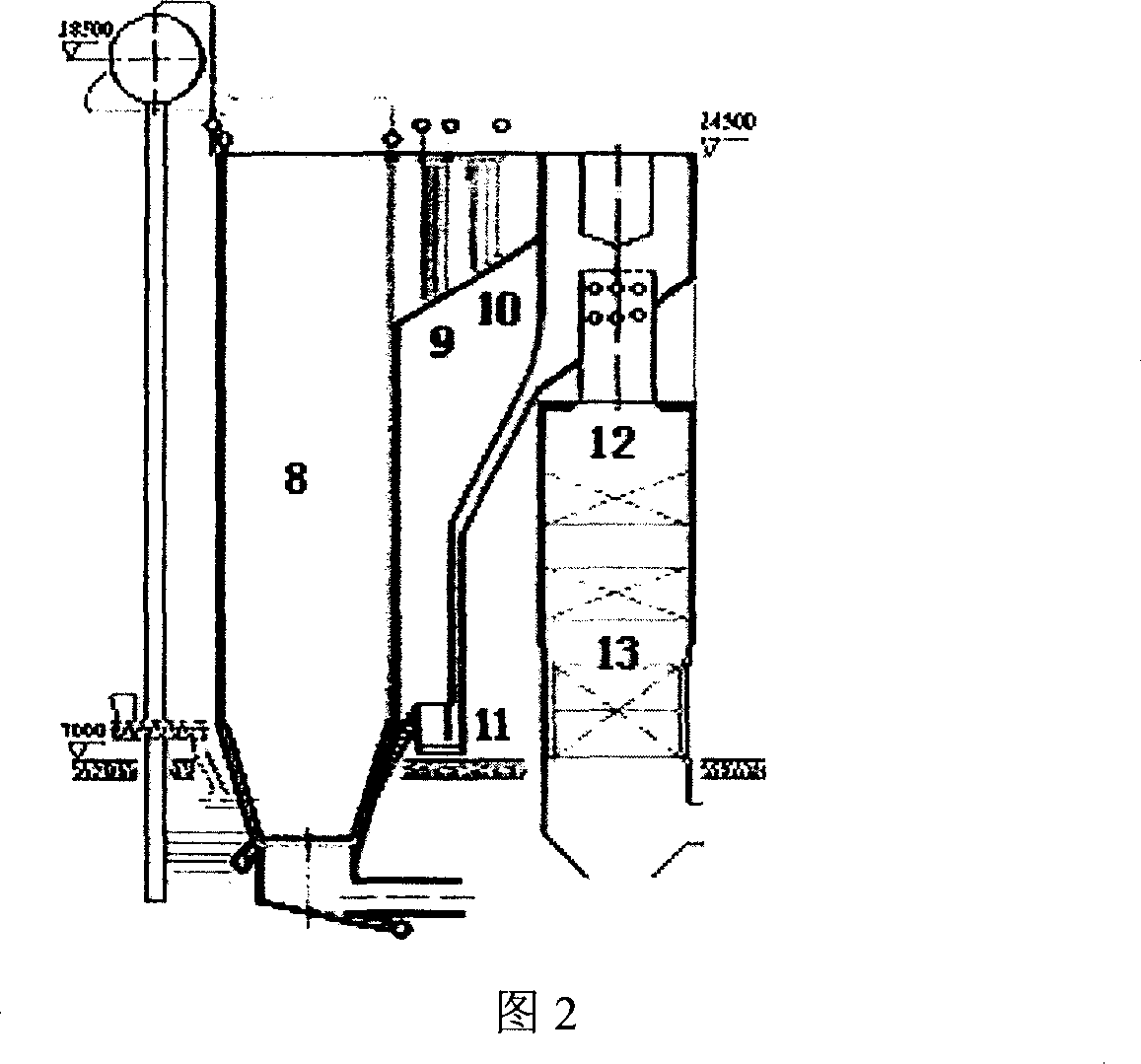

[0022] The overall layout of the lower exhaust cyclo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com