Eccentric wheel rotary engine

A technology of rotating engines and eccentric wheels, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as complex ignition and control methods, low efficiency of reciprocating engines, incomplete fuel combustion, etc., to achieve good combustion performance, Reduce the conversion and transfer process, and facilitate the promotion and use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

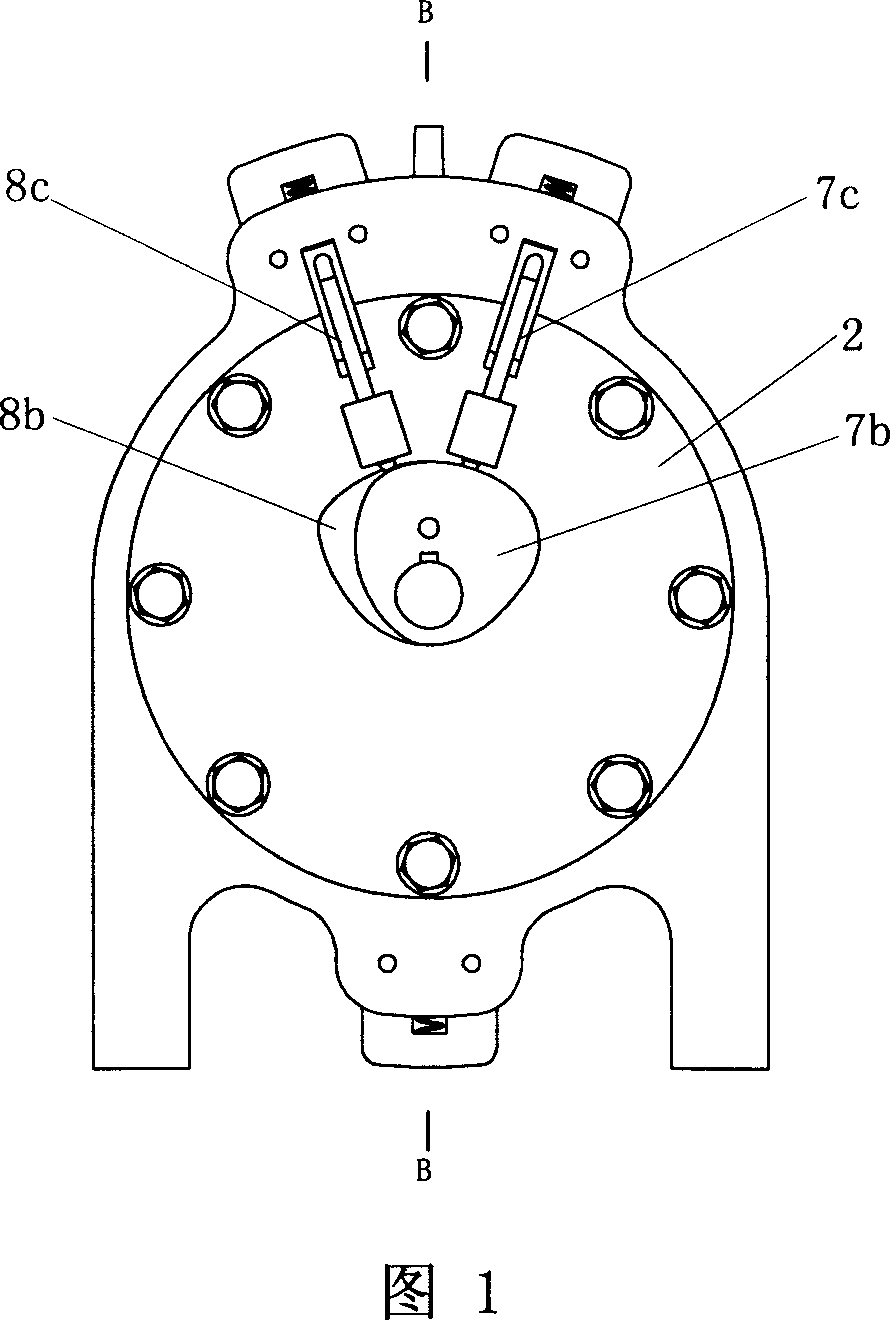

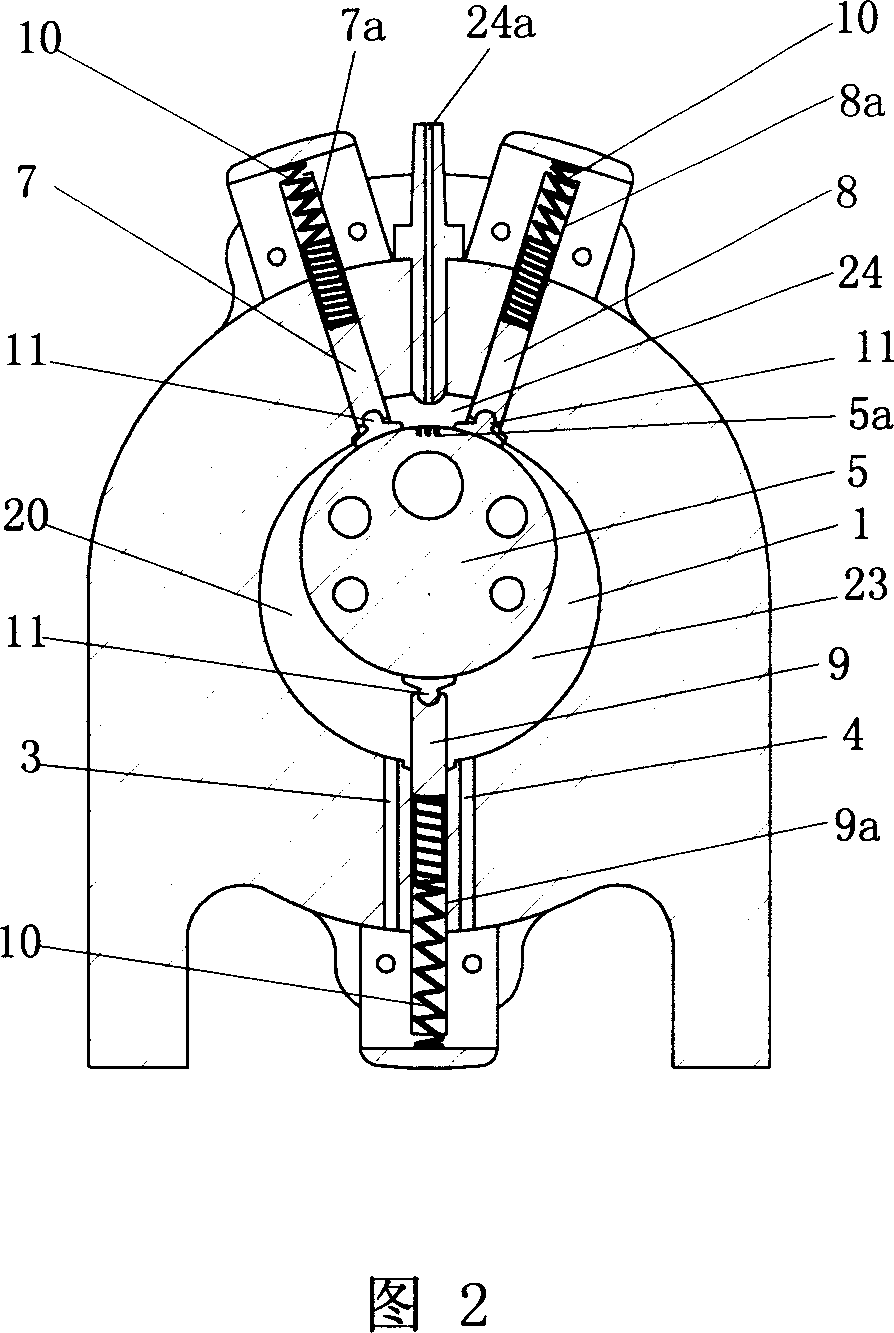

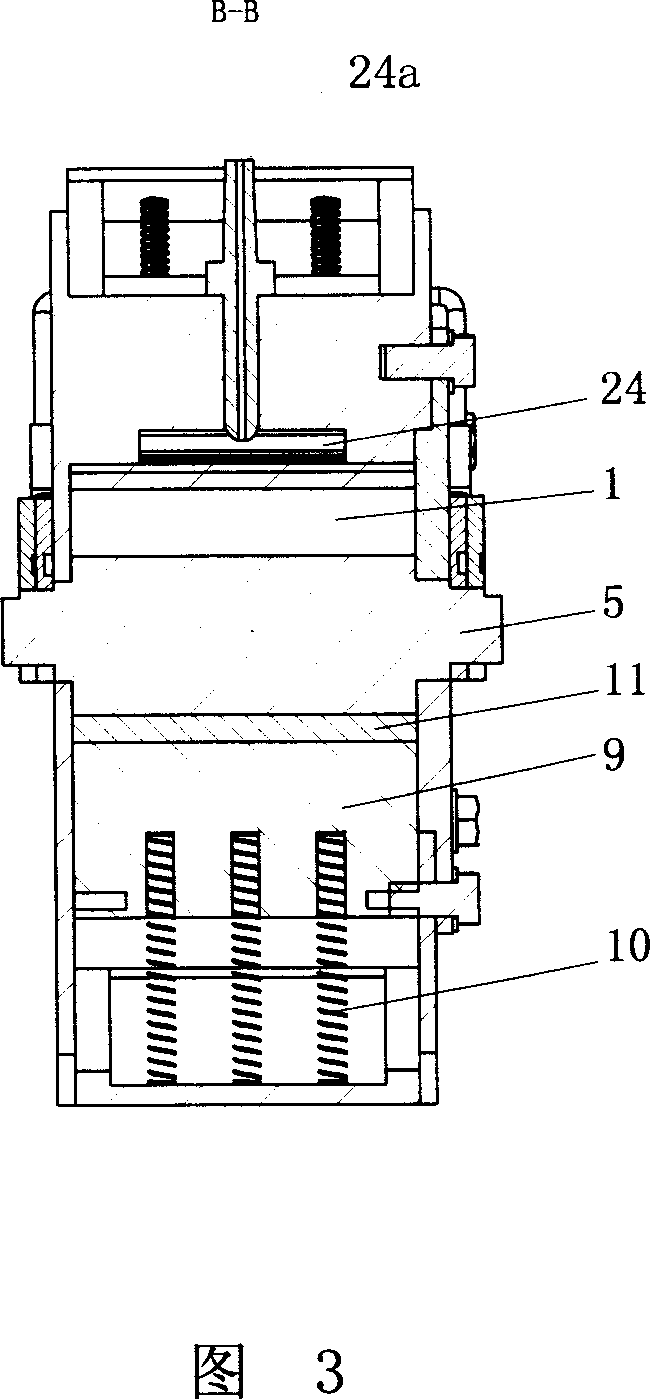

[0043] Figures 1-5 show that a specific embodiment of the present invention is: an eccentric wheel rotary engine, comprising a cylinder 1 with a cylindrical cavity, a cylinder head 2, an air inlet 3, and an exhaust port 4. The cylinder 1 is provided with an eccentric wheel 5 inscribed with the cavity of the cylinder 1, the rotation axis of the eccentric wheel 5 coincides with the center line of the cavity of the cylinder 1, and there is a shallow basin-shaped combustion chamber 24 on the wall of the cylinder 1. The combustion chamber 24 has an oil injection hole 24a connected with the injector.

[0044] The walls of the cylinder 1 on both sides of the combustion chamber 24 are respectively provided with a main baffle chute 7a and an auxiliary baffle chute 8a, and the wall of the cylinder 1 opposite to the combustion chamber 24 is provided with a partition chute 9a; The main baffle plate 7, the secondary baffle plate 8 and the partition plate 9 are fitted in the slot 7a, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com