Thin ic tag and method of producing the same

A manufacturing method and label technology, which are applied in the directions of antenna, printing, antenna support/installation device, etc., can solve the problems of limited miniaturization and limited range of thin IC tags 10, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

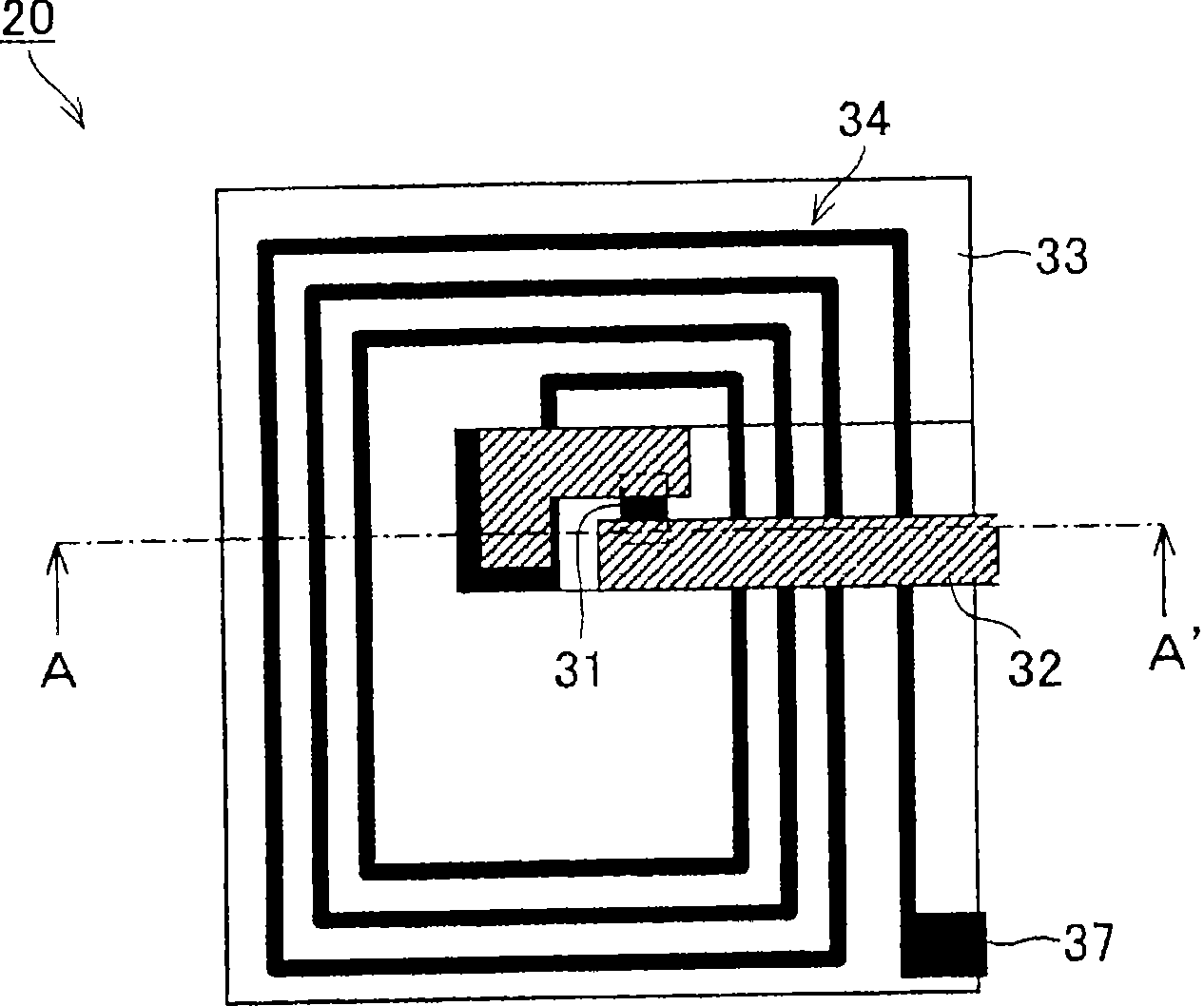

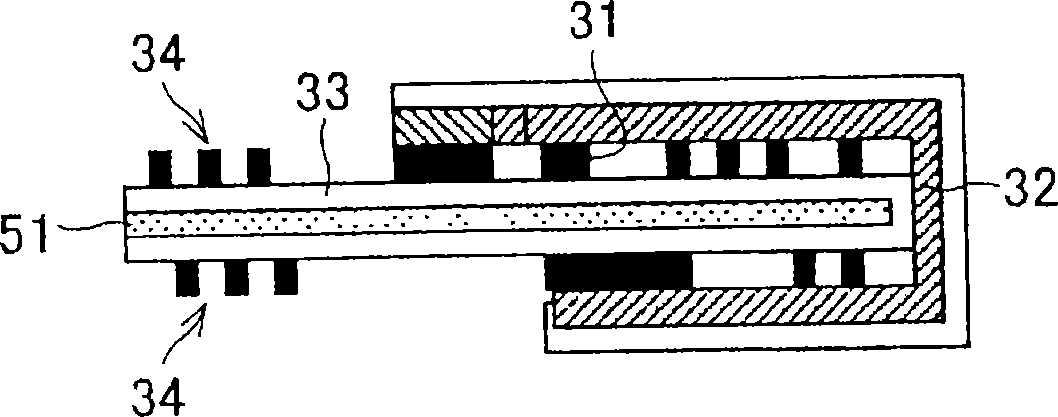

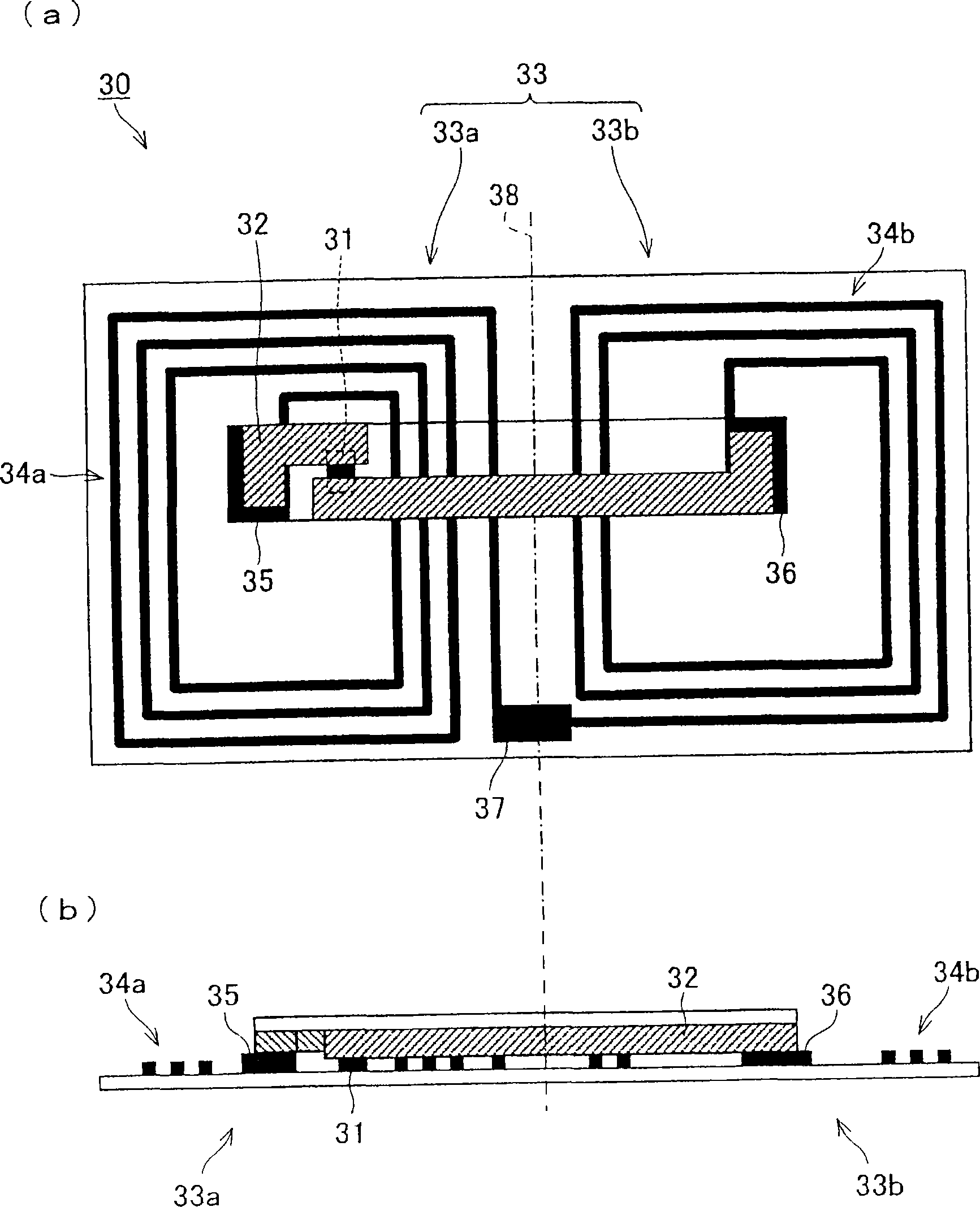

[0067] The following is based on Figure 5 Another embodiment of the thin IC tag and its manufacturing method of the present invention will be described. In addition, for convenience of description, components having the same functions as those described in the first embodiment are denoted by the same reference numerals, and description thereof will be omitted. In this embodiment, differences from the first embodiment described above will be described.

[0068] The thin IC tag described in the first embodiment is configured such that an adhesive layer 51 is formed on the surface of the electronic component holding film 30 opposite to the surface on which the electronic component module 32 and the like are mounted, and the bending direction is As opposed to the surface side on which the adhesive layer 51 is formed, the thin IC tag of this embodiment is configured such that an adhesive layer is formed on the surface of the electronic component holding film 30 on which the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com