Fireproofing extinguishing materials of composite colloid of fly ash for fire in coal bed

A technology for fly ash and fire prevention, applied in fire protection equipment and other directions, can solve the problems of easy agglomeration, deterioration, complex preparation process of composite colloid, etc., and achieve the effects of not easy agglomeration, good moisture resistance, and improved preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Composite colloid material composition:

[0021] Fly ash: water-soluble linear polymer material = 40:1.

[0022] Add the materials in the above ratio into the stirring tank and stir to mix evenly.

[0023] Yaoqiao Coal Mine 7715 light laying face has a strike length of 1320 meters, an inclination length of 187 meters, an inclination angle of 3-8 degrees, and a coal seam thickness of 5.6 meters. Mining began on September 2, 2003, and was completed on December 8, 2004. December 26 The two walls were closed, and after the working face was closed for a week, it was found that the CO gas in the two airtight walls reached 200ppm, and it was still rising.

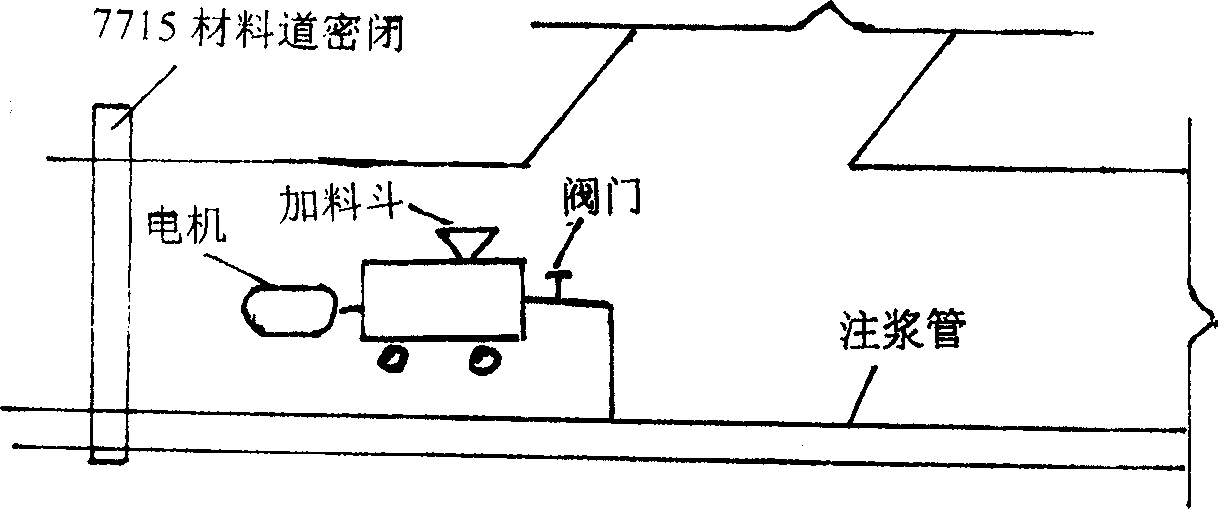

[0024] In February 2005, the large flow glue injection system combined with the colloid preparation machine and the grouting pipe network, such as figure 1 and figure 2 As shown, 4 tons of the composite material of this embodiment is added in the downhole at a ratio of 1%, and about 400m of fly ash is injected. 3 , the...

Embodiment 2

[0026] Composite colloid material composition:

[0027] Fly ash: water-soluble linear polymer material = 40:1.

[0028] The 8516 light-handling working face is located in the third east mining area, the upper part is the 8514 goaf, the strike is 470 meters, the inclination length is 124 meters, the thickness of the coal seam is 3.7 meters, and the inclination angle is 3°. Air leakage from the cracks in the coal pillars along the empty conveying lanes caused spontaneous combustion of coal in the 8514 production line. In February 2005, the CO concentration in the closed wall of the 8514 Liuzi Road was as high as 2600ppm. Drilling holes were drilled along the 8516 material road to the 8514 Liuzi Road to inject fly ash slurry. The effect is not good (there is still 600-800ppm of CO gas in the wall), the goaf seeps seriously into the 8516 material road, and the 8516 working face cannot be produced.

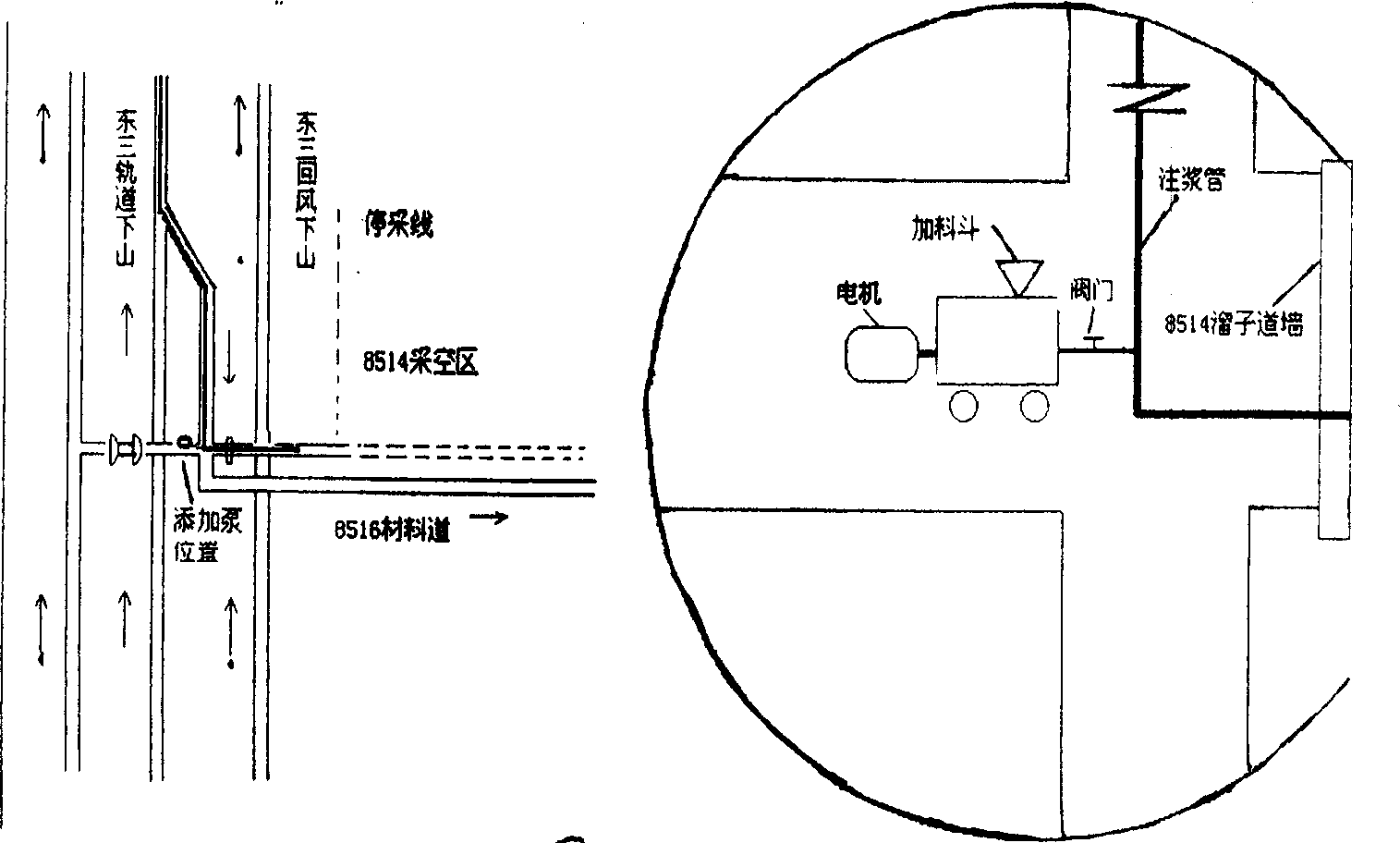

[0029] In early March 2005, a colloid adding pump was installed at the 8516 mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ph | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com