Method and device of heavy oil two stage catalytic cracking reforming and gasoline upgrade coupling

A catalytic cracking and heavy oil technology, applied in the petroleum industry, dealing with hydrocarbon oil, etc., can solve the problem of underutilized gasoline reaction, achieve the effects of inhibiting thermal cracking reaction, reducing losses, and improving gasoline quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

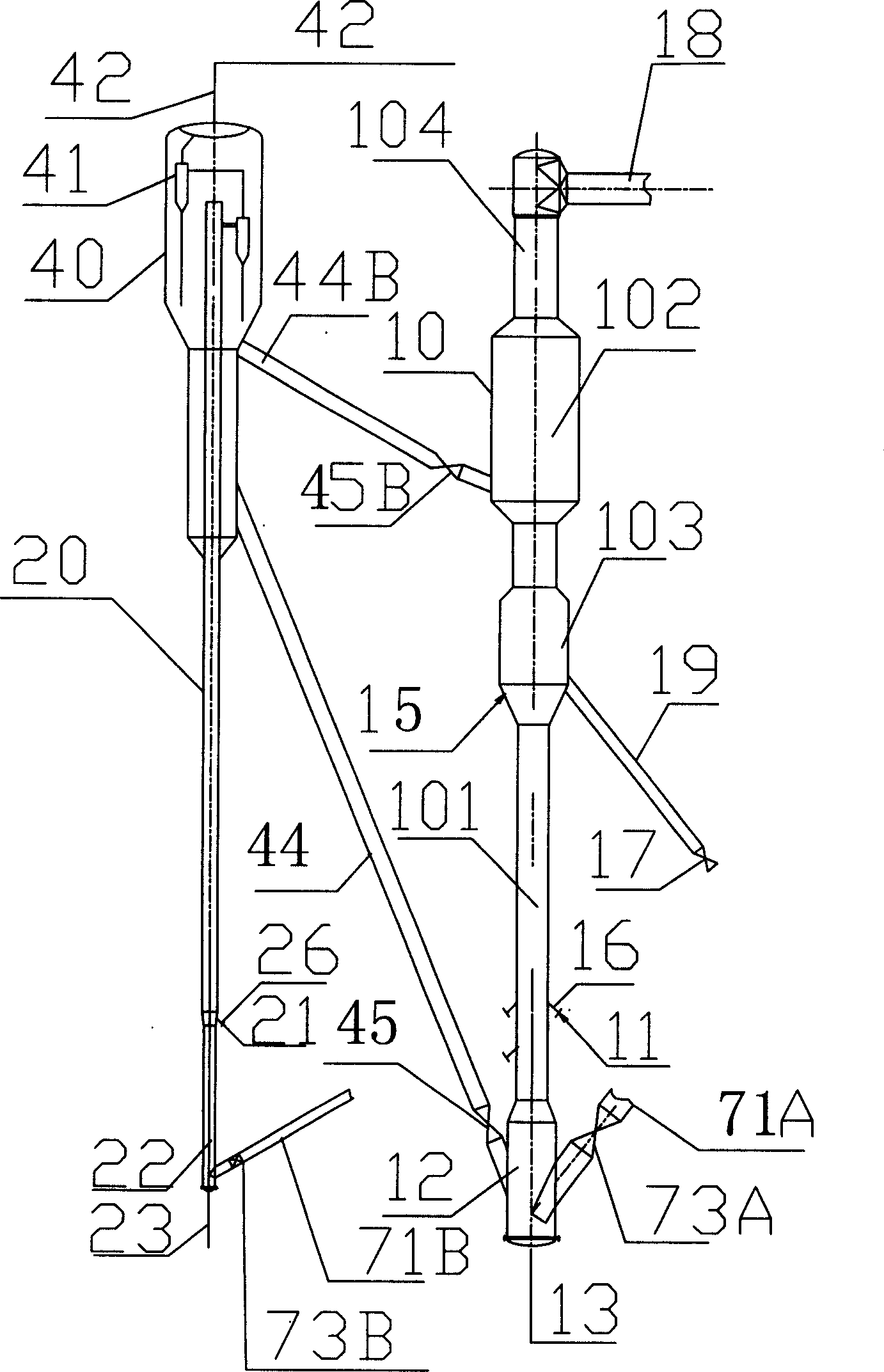

[0029] Example 1. A device for the coupling of heavy oil two-stage catalytic cracking conversion and gasoline upgrading, including a heavy oil reactor 10 and a gasoline reactor 20. The heavy oil reactor 10 includes a cracking reaction section 101 connected in series from bottom to top, and a gas-solid separation section. 103 and upgrading reaction section 102, the cracking reaction section 101 and upgrading reaction section 102 of the heavy oil reactor 10 both adopt the riser type. 11 is feedstock oil, 16 is feedstock oil inlet, 12 is catalyst mixing and pre-lifting section, 13 is catalyst lifting medium, 18 is outlet pipe of heavy oil reactor, 71A, 71B are regeneration standpipes, 73A, 73B are regeneration slide valves. The gasoline reactor 20 adopts a riser type, and a catalyst delivery pipe 44B is installed between the gasoline reaction settler 40 at the outlet and the reforming reaction section 102 of the heavy oil reactor 10, and 45B is a catalyst slide valve after the gas...

Embodiment 2

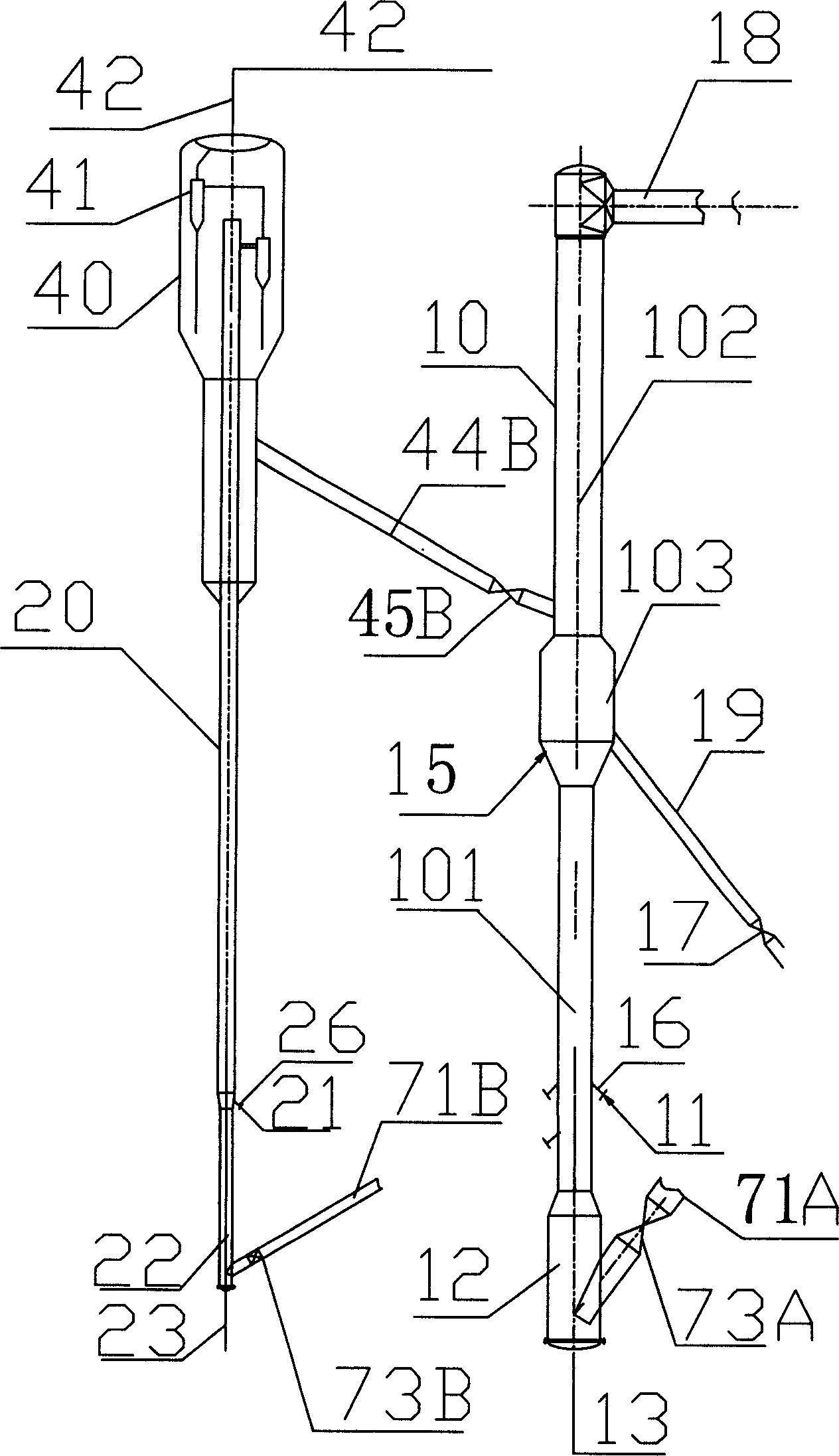

[0033] Example 2. In this example, the schematic diagram of the device structure of heavy oil two-stage catalytic cracking conversion and gasoline upgrading coupling is shown in Figure 4 , the structural diagram of the anti-re-device is shown in Figure 5 . The difference with the device in Example 1 is that a catalyst return pipe 24 and 25 are slide valves between the gasoline settler 40 and the bottom of the gasoline reactor 20; a catalyst delivery pipe is arranged between the gasoline settler 40 and the bottom of the heavy oil reactor 10 44. During use, the slide valve 45 on the delivery pipe is closed.

[0034] The reaction materials are: Daqing atmospheric heavy oil, 100t / h heavy oil, gasoline feed is catalytic gasoline from other devices, 40t / h; heavy oil is preheated at 220°C, gasoline is at 40°C; heavy oil reactor feedstock oil and recycled oil are mixed into four routes Entering the riser of the first reaction zone, gasoline enters the reactor in two ways; the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com