Preparation method of calcium sulfate nanometer material

A nanomaterial, calcium sulfate technology, applied in the field of preparation of calcium sulfate nanomaterials, can solve the problems of high reaction temperature requirements, difficult large-scale production, complex operation, etc., and achieve the effects of reduced production costs, convenient operation, and enhanced fluorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

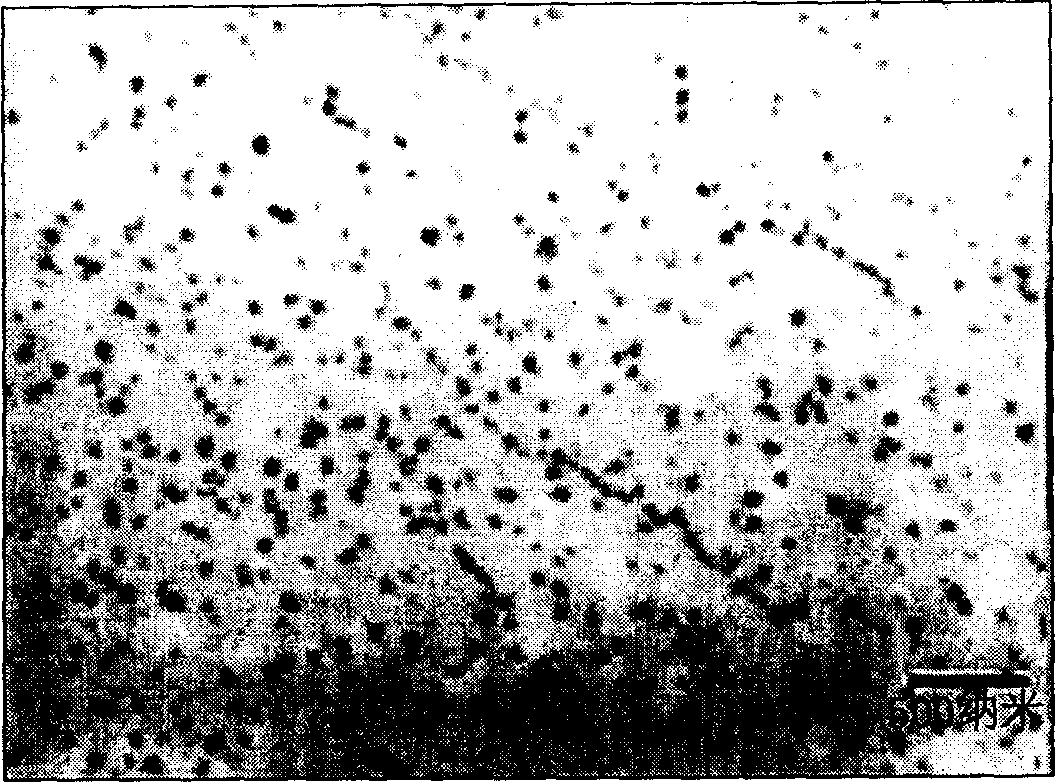

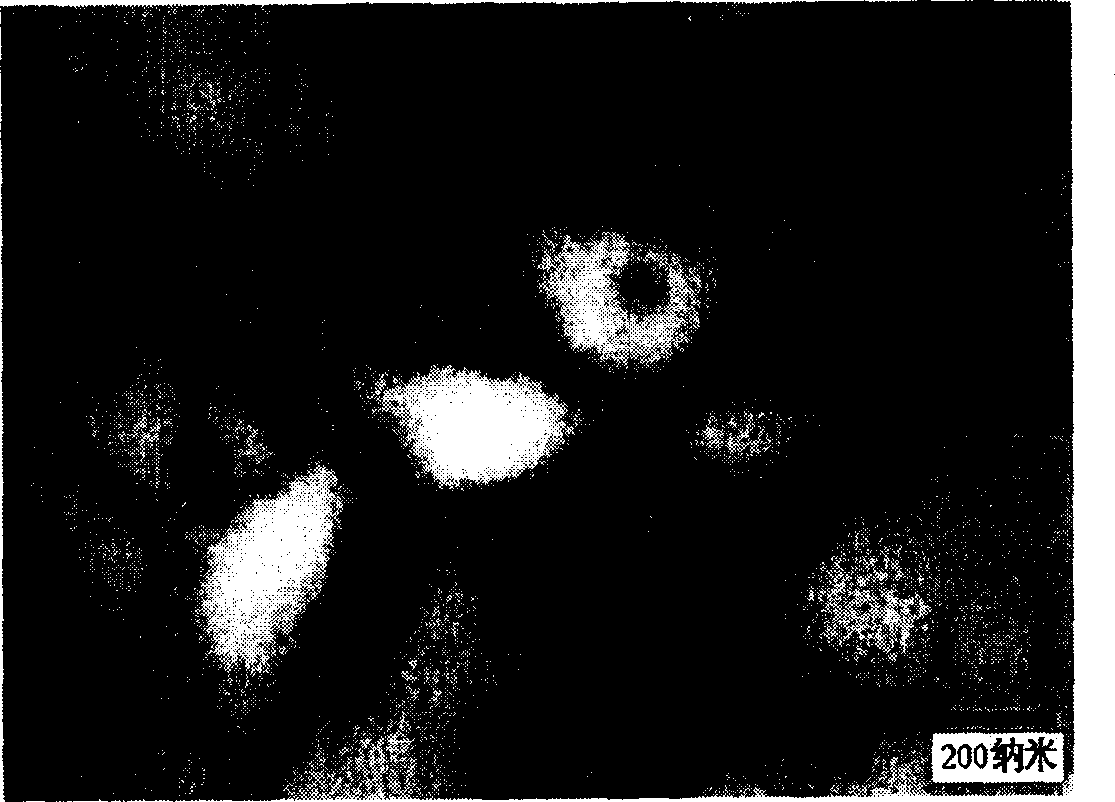

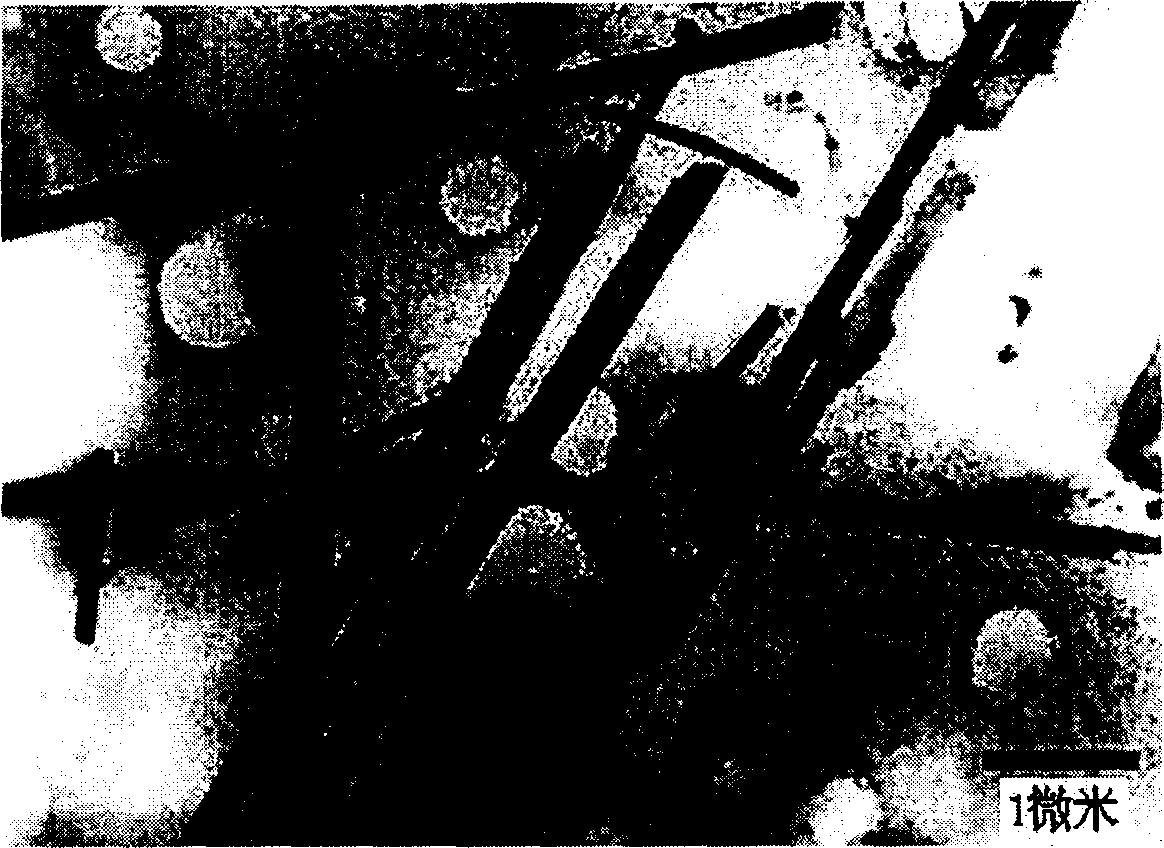

Image

Examples

Embodiment 1

[0037] (1) Weigh 0.0025 moles of CaCl respectively 2 and Na 2 SO 4 , and then were dissolved in 25 ml of distilled water to make CaCl with a molar concentration of 0.10 mol / L 2 and Na 2 SO 4 solution;

[0038] (2) Add 1.5 milliliters of any solution prepared in step (1) to the Erlenmeyer flask in sequence, 5 milliliters of C 12 E. 9 1 milliliter of n-pentanol and 40 milliliters of cyclohexane were stirred for 5 minutes to form a transparent and uniform reversed-phase micelle A solution, and another solution in step (1) was prepared into another reversed-phase micelle B in the same way solution;

[0039] (3) Mix the two reversed-phase micellar solutions obtained in step (2), stir for 2 minutes to make them fully mixed, and after standing for 1 minute, the reversed-phase micellar solution is demulsified and separated with acetone, and the acetone is added The amount is 5 milliliters, the product is washed three times with absolute ethanol and distilled water, and vacuum-...

Embodiment 2

[0042] (1) Weigh 0.0025 moles of CaCl respectively 2 and Na 2 SO 4 , and then were dissolved in 25 ml of water to make CaCl with a molar concentration of 0.10 mol / L 2 and Na 2 SO 4 solution;

[0043] (2) A: Add 1.5 milliliters of CaCl prepared in step (1) to the Erlenmeyer flask2 solution, 5 ml C 12 E. 9 , 1 milliliter of n-pentanol and 40 milliliters of cyclohexane, stirred to form a transparent and uniform reversed-phase micellar solution;

[0044] B: Add 1.5 milliliters of Na prepared in step (1) respectively to the Erlenmeyer flask 2 SO 4 solution, 5 ml C 12 E. 9 , 1 milliliter of n-pentanol and 40 milliliters of cyclohexane, stirred to form another transparent and uniform reversed-phase micellar solution;

[0045] (3) Stir two kinds of reversed-phase micellar solutions of A and B gained in step (2), make it mix uniformly, let it stand for reaction for 5 minutes, separate the reversed-phase micellar solution with acetone demulsification, and the acetone addition...

Embodiment 3

[0047] (1) Weigh 0.0025 moles of CaCl respectively 2 and Na 2 SO 4 , and then were dissolved in 25 ml of water to make CaCl with a molar concentration of 0.10 mol / L 2 and Na 2 SO 4 solution;

[0048] (2) A: Add 1.5 milliliters of CaCl prepared in step (1) to the Erlenmeyer flask 2 solution, 5 ml C 12 E. 9 , 1 milliliter of n-pentanol and 40 milliliters of cyclohexane, stirred to form a transparent and uniform reversed-phase micellar solution;

[0049] B: Add 1.5 milliliters of Na prepared in step (1) respectively to the Erlenmeyer flask 2 SO 4 solution, 5 ml C 12 E. 9 , 1 milliliter of n-pentanol and 40 milliliters of cyclohexane, stirred to form another transparent and uniform reversed-phase micellar solution;

[0050] (3) Stir two kinds of reversed-phase micellar solutions of A and B obtained in step (2), make it mix uniformly, leave to stand for reaction for 12 hours, separate the reversed-phase micellar solution with acetone demulsification, the acetone additio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com