Production method for pattern-worked porous molding or nonwoven fabric, and electric circuit components

一种无纺织物、制造方法的技术,应用在电气元件、多孔电介质、印刷电路零部件等方向,能够解决难形成深穿透孔和沟槽等问题,达到低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0079] Porous drawn PTFE (trade name HP010-60, manufactured by SMMITOMO ELECTRIC FINEPOLYMER, INC) with a pore size of 0.1 μm, a porosity (ASTM D-792) of about 50%, and a film thickness of 60 μm was smoothed and set on a glass plate , and secure it with plastic straps around its edges to prevent movement. On the porous drawn PTFE, instant adhesive (trade name Aron Alpha, manufactured by TOAGOSEI Co., Ltd.) was thinly applied. Then, on the instant adhesive layer, a mask made of stainless steel having a slit of 100 μm in width and 5 mm in length opened thereon was provided to have a thickness of 0.05 mm. The membrane was left standing overnight to allow the instant adhesive to dry sufficiently to secure the stainless steel mask to the porous drawn PTFE.

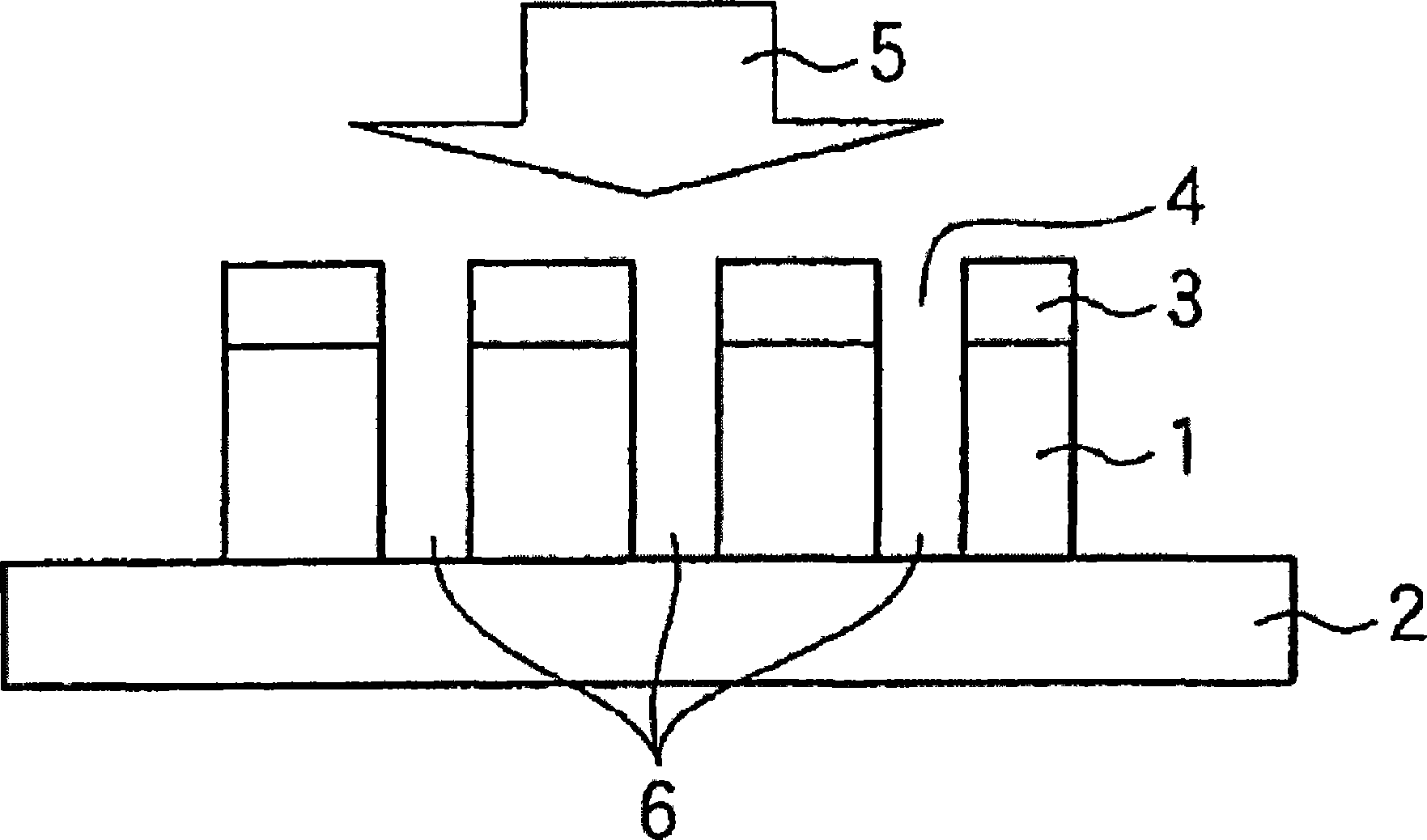

[0080] From above a mask made of stainless steel, the sandblasting process is performed by compressed air using aluminum abrasive grains with an average grain diameter of approximately 5 μm. By transmitted light detection, it...

example 2

[0084] A porous drawn PTFE membrane with a pore size of 5 μm, a porosity of about 80%, and a membrane thickness of 100 μm (trade name WP500-100, manufactured by SMMITOMO ELECTRIC FINE POLYMER, INC.) was smoothed and set on a glass plate, and fixed with adhesive tape in case of movement. An instant adhesive (trade name Aron Alpha, manufactured by TOAGOSEI Co,. Ltd.) was thinly applied on the porous drawn PTFE. Then, on the instant adhesive layer, a mask made of stainless steel in which a slit of 100 μm in width and 5 mm in length was opened was provided to have a thickness of 0.05 mm. The membrane was left standing overnight to allow the instant adhesive to dry sufficiently to secure the stainless steel mask to the porous drawn PTFE.

[0085] From above a stainless steel mask, the sandblasting process is performed by compressed air using aluminum abrasive grains with an average grain diameter of approximately 5 μm. By transmitted light detection, it was confirmed that slit pe...

example 3

[0089] A porous drawn PTFE membrane with a pore size of 5 μm, a porosity of about 80%, and a membrane thickness of 100 μm (trade name WP500-100, manufactured by SMMITOMO ELECTRIC FINE POLYMER, INC.) was smoothed and set on a glass plate, and fixed with an adhesive tape to Anti-movement. An instant adhesive (trade name Aron Alpha, manufactured by TOAGOSEI Co,. Ltd.) was thinly applied on the porous drawn PTFE. Then, on the adhesive layer, a mask made of stainless steel having a slit of 100 µm in width and 5 mm in length opened thereon was provided to have a thickness of 0.05 mm. The membrane was left standing overnight to allow the instant adhesive to dry sufficiently to secure the stainless steel mask to the porous drawn PTFE.

[0090]From above the stainless steel mask, the sandblasting process is carried out by compressed air using sodium chloride abrasive grains with an average grain diameter of approximately 5 μm. The formation of slit-penetrating grooves in the porous d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com