Tyre air inflating device of tyre road pressing machine

A technology for tire rollers and inflators, which is used in transportation and packaging, vehicle maintenance, vehicle maintenance/repair, etc., can solve problems such as poor sealing, inability to adjust inflation pressure, inconvenient use and operation, and maintain working pressure. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

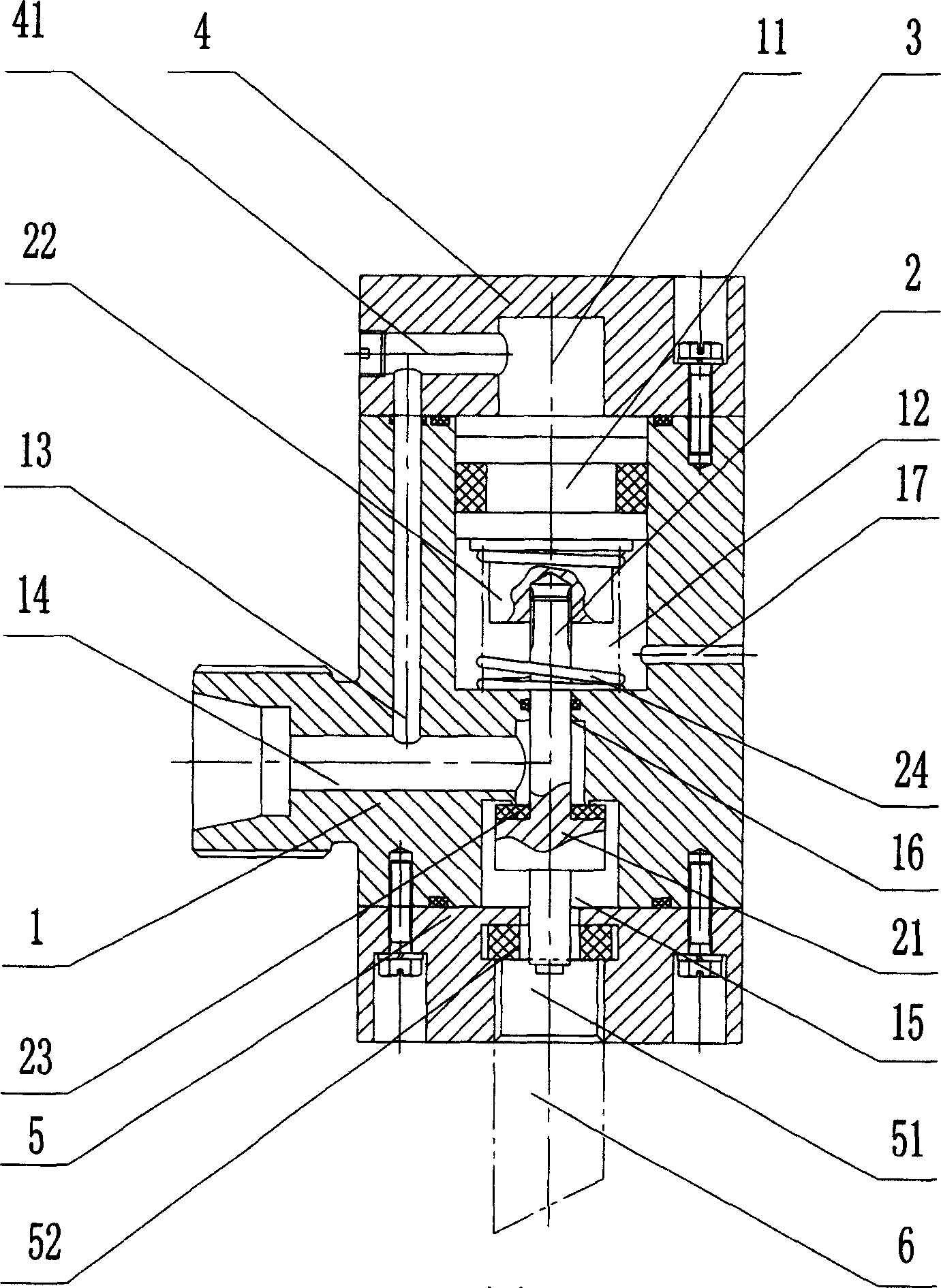

[0024] Embodiment 1: as figure 2 As shown, the tire inflation device of the tire roller of the present invention includes a valve body 1, a valve stem 2 and a piston 3; 3. Divide the upper part of the inner cavity of the valve body 1 into a pressure accumulator chamber 11 and an elastic chamber 12; the two ends of the valve body 1 are connected with an upper end cover 4 and a lower end cover 5 by bolts, and the valve body 1 is also provided with a valve body air guide channel 13. One end of the valve body air guide channel 13 communicates with the air inlet 14 provided on the valve body 1, and the other end communicates with the pressure storage chamber 11 through the end cover air guide channel 41 opened on the upper end cover 4; the upper end of the valve stem 2 is threaded A guide seat 22 is connected, and a spring 24 is set on the guide seat 22. The contact area between the guide seat 22 and the piston 3 is large, which ensures that the valve stem does not deflect during ...

Embodiment 2

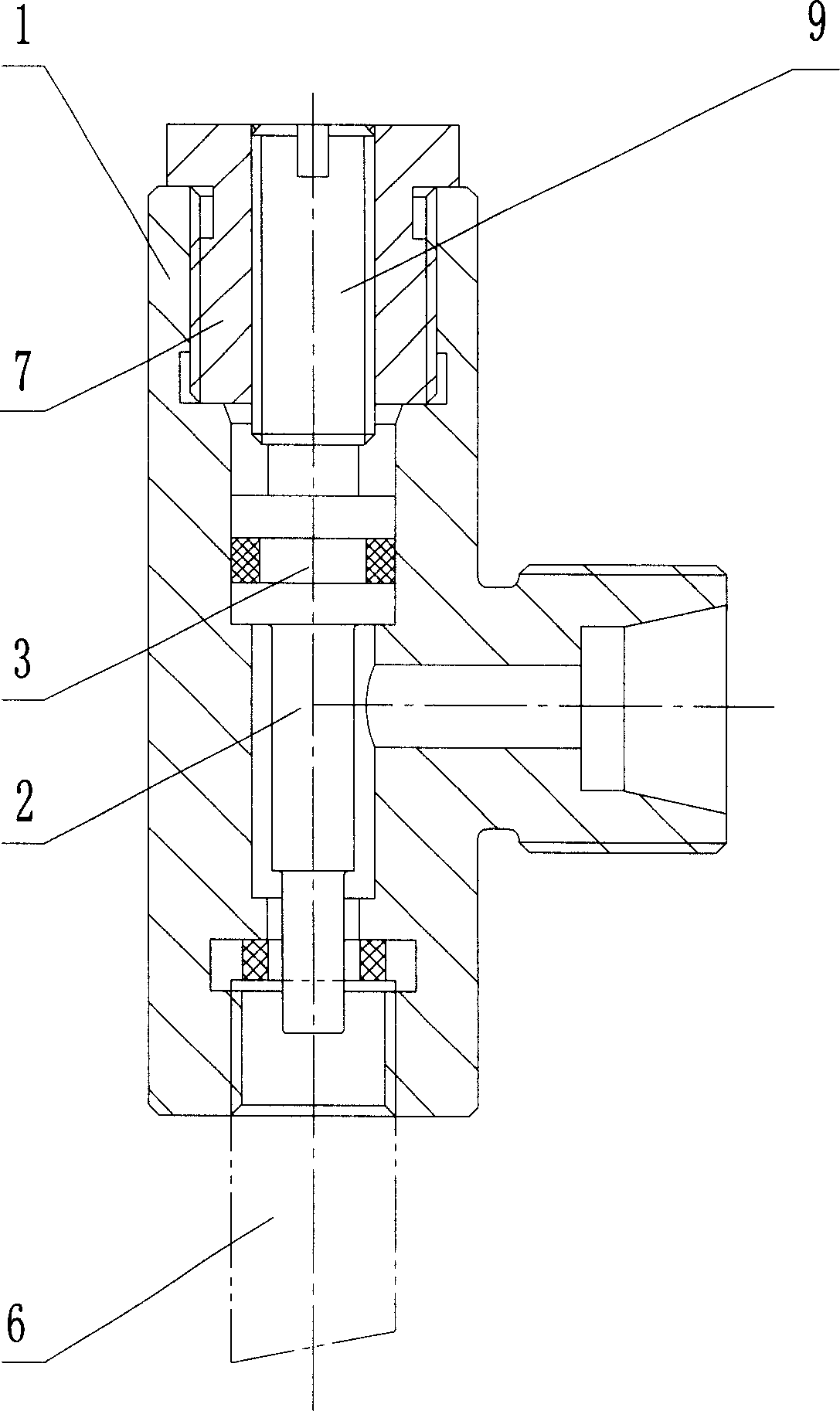

[0026] Embodiment 2: as image 3 As shown, the tire inflation device of the tire roller of the present invention includes a valve body 1, a valve stem 2 and a piston 3; 3. Divide the upper part of the inner cavity of the valve body 1 into a pressure accumulator chamber 11 and an elastic chamber 12; the two ends of the valve body 1 are connected with an upper end cover 4 and a lower end cover 5 by bolts, and the valve body 1 is also provided with a valve body air guide channel 13. One end of the valve body air guide channel 13 communicates with the air inlet 14 provided on the valve body 1, and the other end communicates with the pressure storage chamber 11 through the end cover air guide channel 41 opened on the upper end cover 4; the upper end of the valve stem 2 is threaded A guide seat 22 is connected, and a spring 24 is set on the guide seat 22. The contact area between the guide seat 22 and the piston 3 is large, which ensures that the valve stem 2 does not deflect during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com