Evaluating system for dust removing technology of coal burning power generation plant

A technology for coal-fired power plants and electrostatic precipitators, applied in information technology support systems, electrical digital data processing, special data processing applications, etc. random effect

Inactive Publication Date: 2010-08-25

XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the use of visual programming tool Visual Basic and SQL Server database technology is widely used in the design of electrostatic precipitator control system, but based on fuzzy mathematics, the method of using Visual Basic and SQL Server to realize the selection and design of electrostatic precipitator has not yet been discussed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

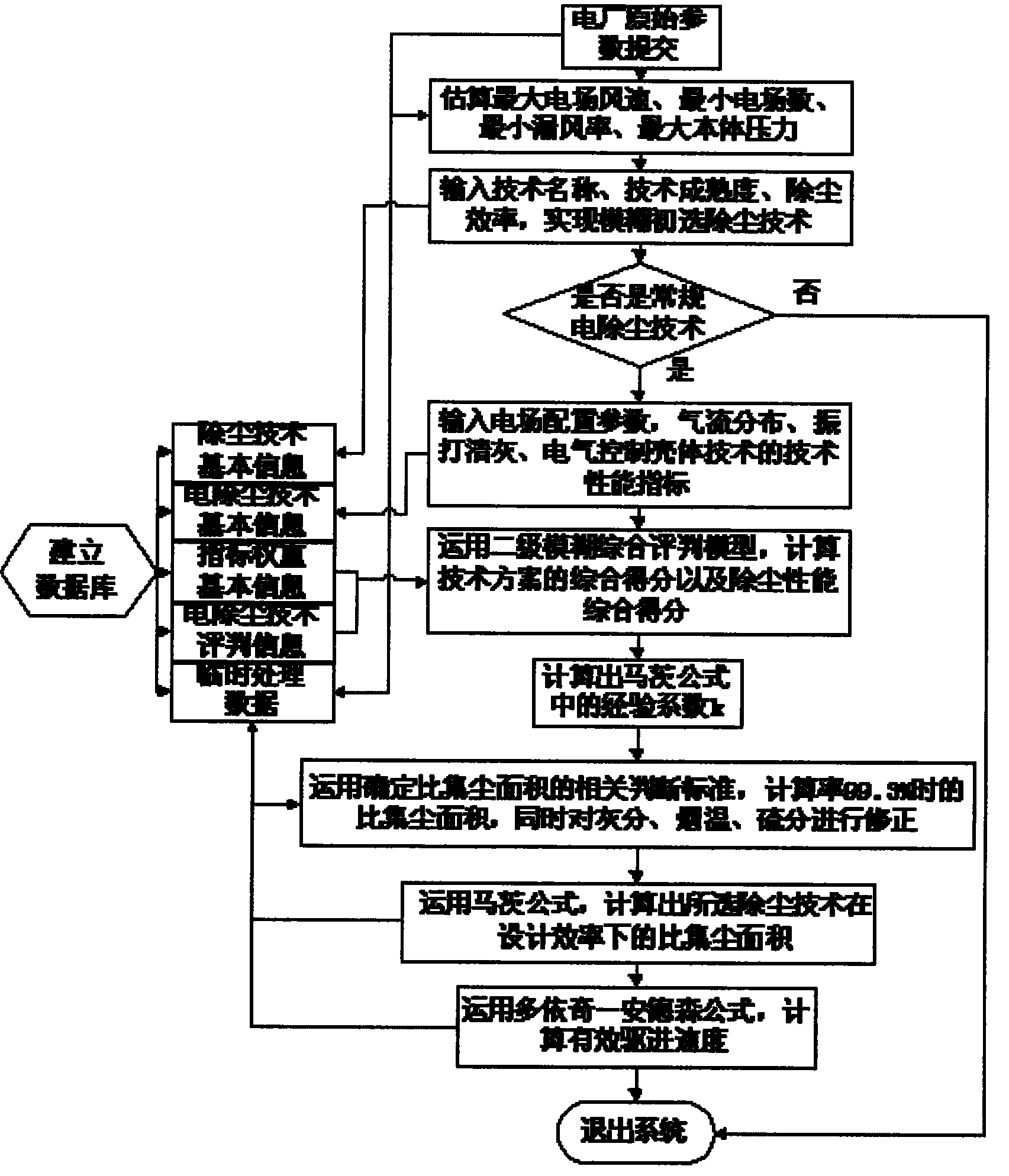

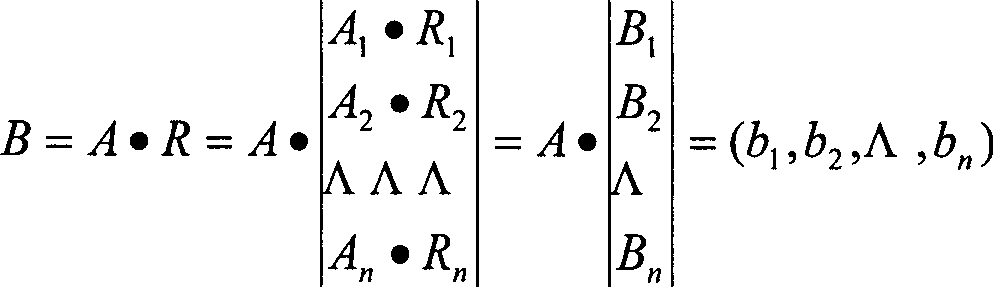

The present invention discloses a kind of electric de-dusting technology assessing system for coal burning power plant. Electric de-dusting technological scheme is assessed by means of comprehensive fuzzy assessing model, the experiment data and the integrated expertise, its specific dust collecting area under certain work condition and its de-dust efficiency is predicted and effective de-dust speed is calculated. The assessing system may be used in determining the electric de-dusting scheme for coal burning power plant accurately, quickly and conveniently.

Description

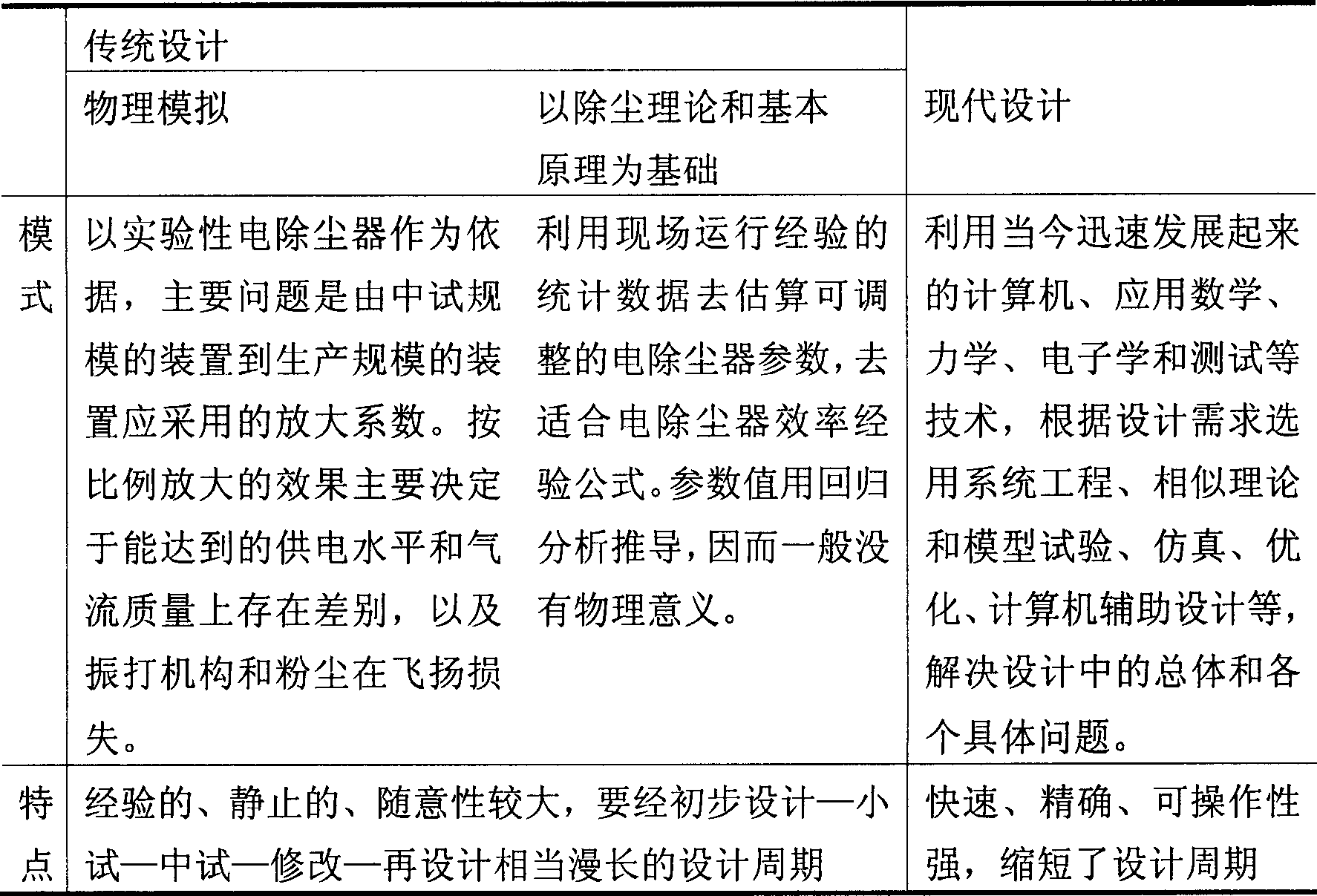

technical field The invention belongs to the field of type selection and design of electric dust collectors, in particular to an evaluation system for electric dust removal technical solutions of coal-fired power plants. Background technique Type selection design is to determine the main parameters of the electrostatic precipitator such as model specification, airflow distribution mode, pole matching form, power supply mode and supporting power supply model specification according to the user's use requirements and the original parameters provided, and draw the electric dust collector Outline diagram, load diagram, electrical schematic diagram, layout diagram, etc. of the dust collector for further structural design. The basic problem is to determine the main design parameters, such as the size of the electrostatic precipitator, pole matching form, air distribution mode, rapping mechanism, and power supply conditions required to adapt to certain dust characteristics. There ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G06Q10/00G06F17/50G06Q50/00

CPCY02E60/76Y04S40/22Y02E60/00

Inventor 党小庆韩小梅闫东杰高蕊芳杨雪莲边靖樊彦玲李伟马广大

Owner XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com