Control system for light hardening quick forming resin level

A control system and resin liquid technology, applied in liquid level control, control/regulation system, non-electric variable control, etc., can solve the problems of resin liquid level fluctuation, affecting the quality of molded parts, slow resin replenishment, etc., to achieve precision and The effect of increasing the speed, shortening the liquid level stabilization time, and overcoming the inclination of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

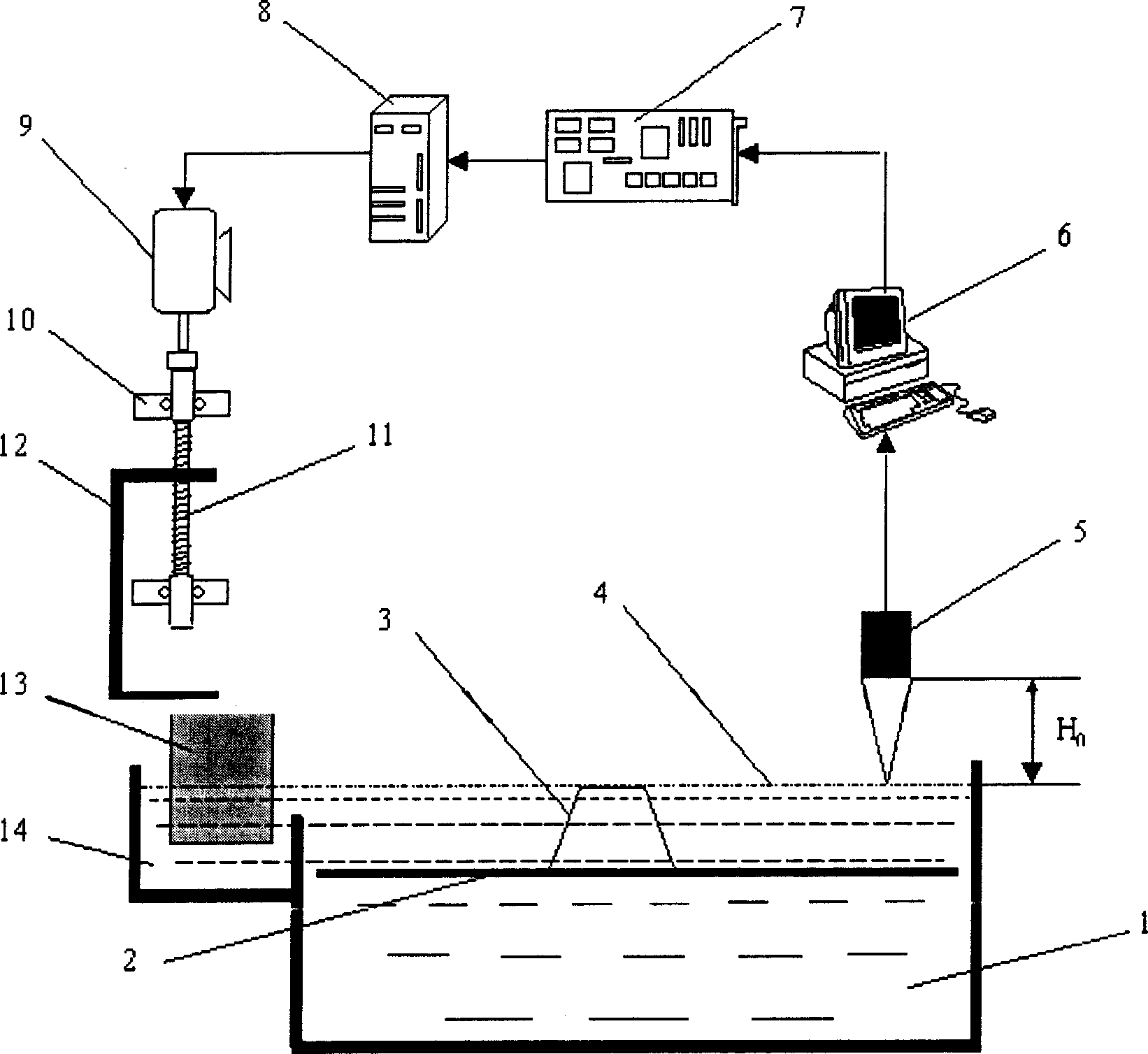

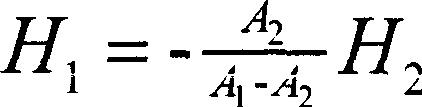

[0011] see figure 1 , the resin liquid level control system that is used for photocuring rapid prototyping process of the present invention comprises a molding resin tank 1 of splendid attire photosensitive resin, is provided with the workbench 2 that drives workpiece 3 to move up and down in molding resin tank 1; 1 is provided with an auxiliary tank 14 for replenishing resin; a reflective laser position sensor 5 for detecting the position of the liquid level is also provided above the resin liquid level 4; the reflective laser position sensor 5 is connected with the computer 6, and the received The liquid level position signal is sent to the computer; the computer 6 is connected with the driver 8 and the motor 9 through the control card 7, the output end of the motor 9 is connected with the sinker compensation mechanism, the sinker compensation mechanism is connected with the sinker 13, and the motor 9 is connected with the driver 8 , The control card 7 receives the control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com