Hollow core photon crystal fiber-optic fiber gas sensor

A hollow-core photonic crystal and gas sensor technology, which is applied in the measurement of color/spectral characteristics, etc., can solve the problems of difficult control of absorption optical path, complex system device, large optical path coupling loss, etc., and achieves light weight, flexible and simple structure, and reduced The effect of light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

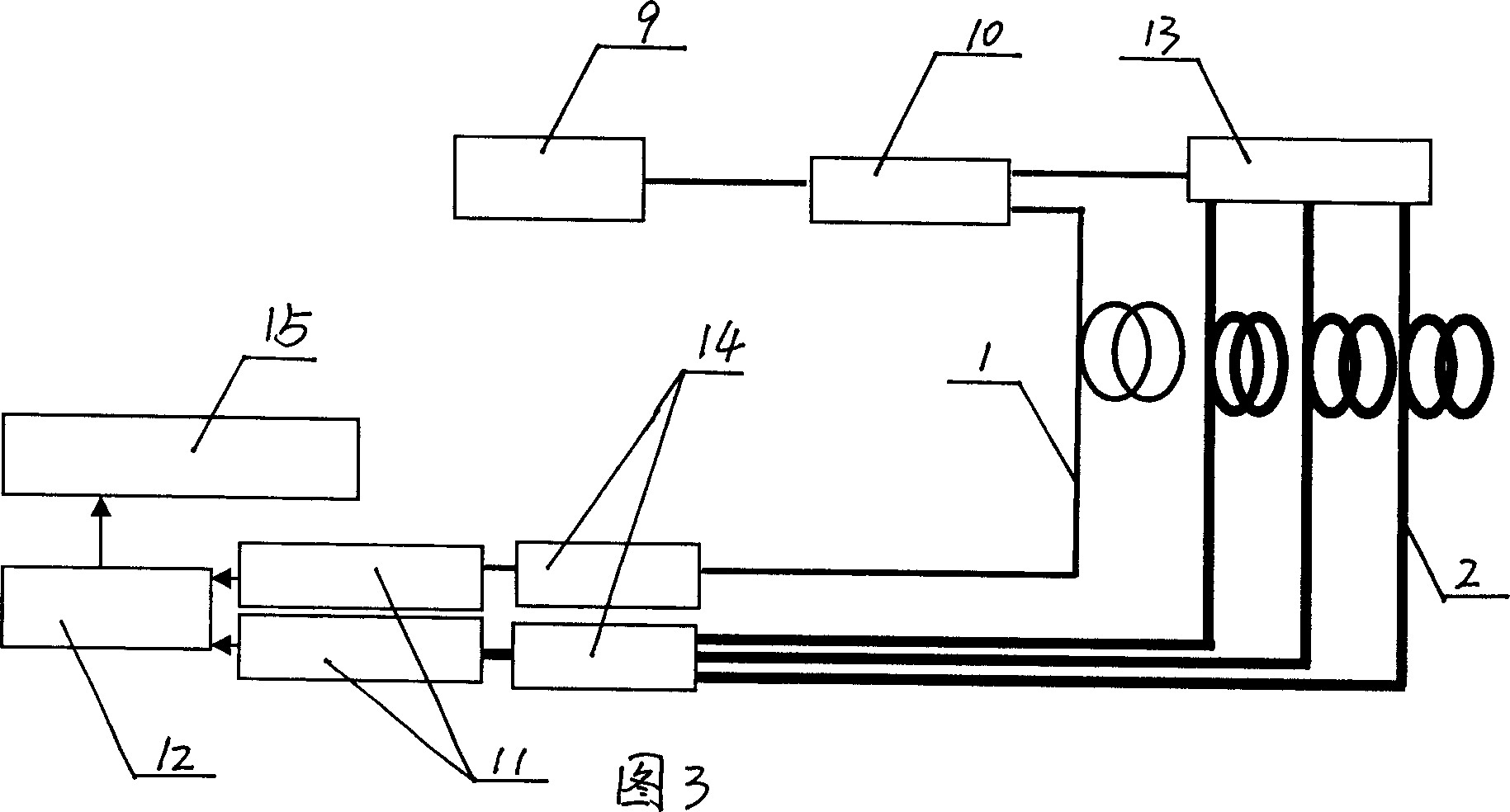

[0021] A hollow-core photonic crystal fiber gas sensor, comprising a light source 9, a light guide gas chamber optical path connected to the light source 9 through an ordinary optical fiber 1, an optical splitter 10, and a reference optical path that adopts an ordinary optical fiber 1, and is arranged in the light guide gas chamber The other end of the optical path and the reference optical path includes a photodiode 11 and a lock-in amplifier 12 for providing signals for the external gas concentration monitoring circuit 15. Hollow-core photonic crystal fiber 2.

[0022] An optical switch 13 is provided at the light-incoming end of the optical path of the light-guiding gas chamber, and the optical splitter 10 can connect multiple hollow-core photonic crystal fibers 2 with air-permeable micropores 3 on it through the optical switch 13, and can be controlled by controlling the optical switch. Realize the measurement of gas concentration in multiple locations;

[0023] The light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com