Self-sealed compensated beam-pumping stabilizer

A technology for pumping oil and sucker rods, which is applied in the direction of production fluid, drilling equipment, wellbore/well components, etc., and can solve the problems of reduced centralizing effect, poor wear resistance, and easy movement of ordinary card-mounted centralizers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

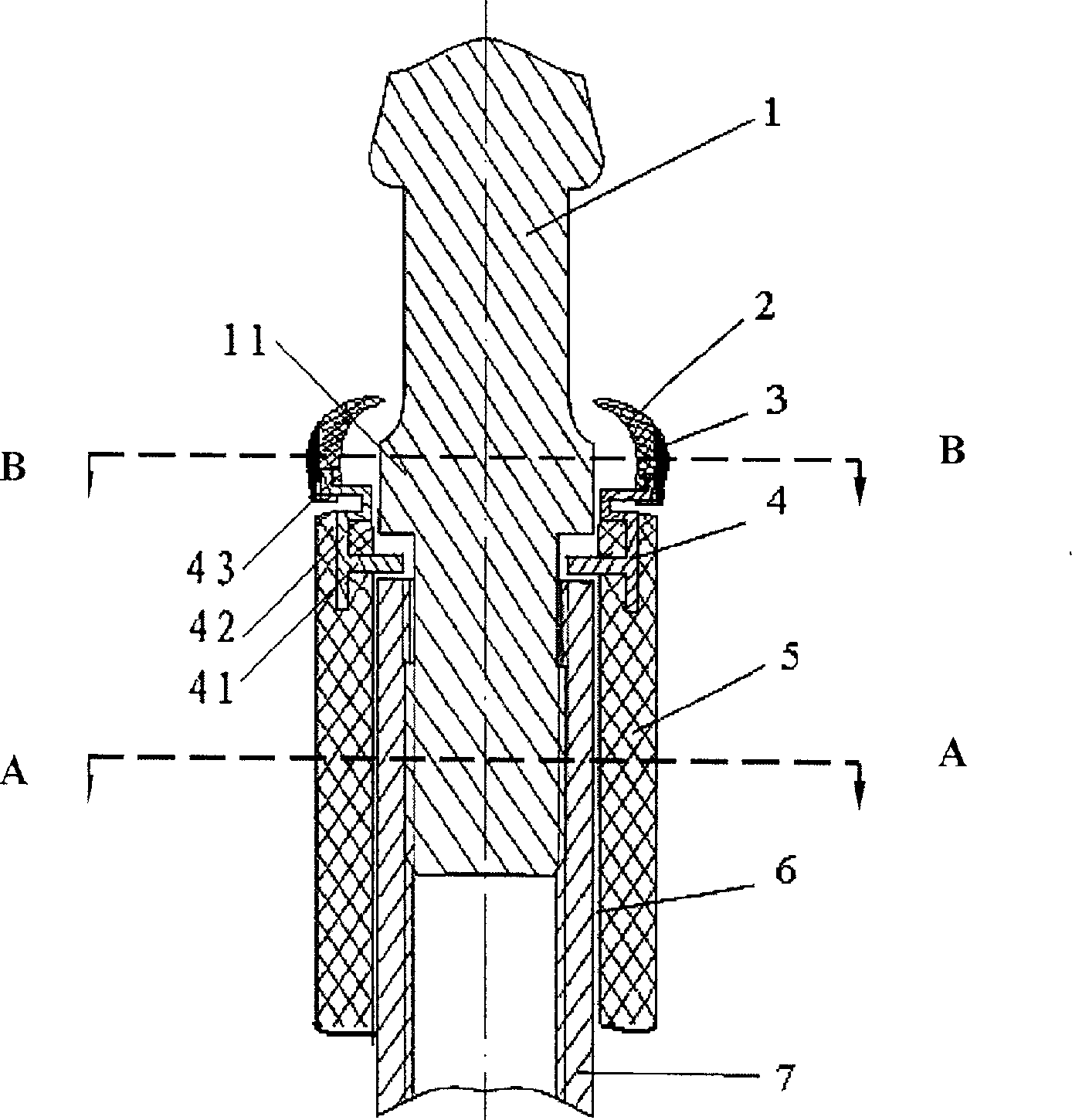

[0011] The invention discloses a self-styled compensation oil pumping and straightening device, which is used in a rod string oil well pump and plays the function of self-styled compensation oil pumping during the process of straightening the sucker rod string.

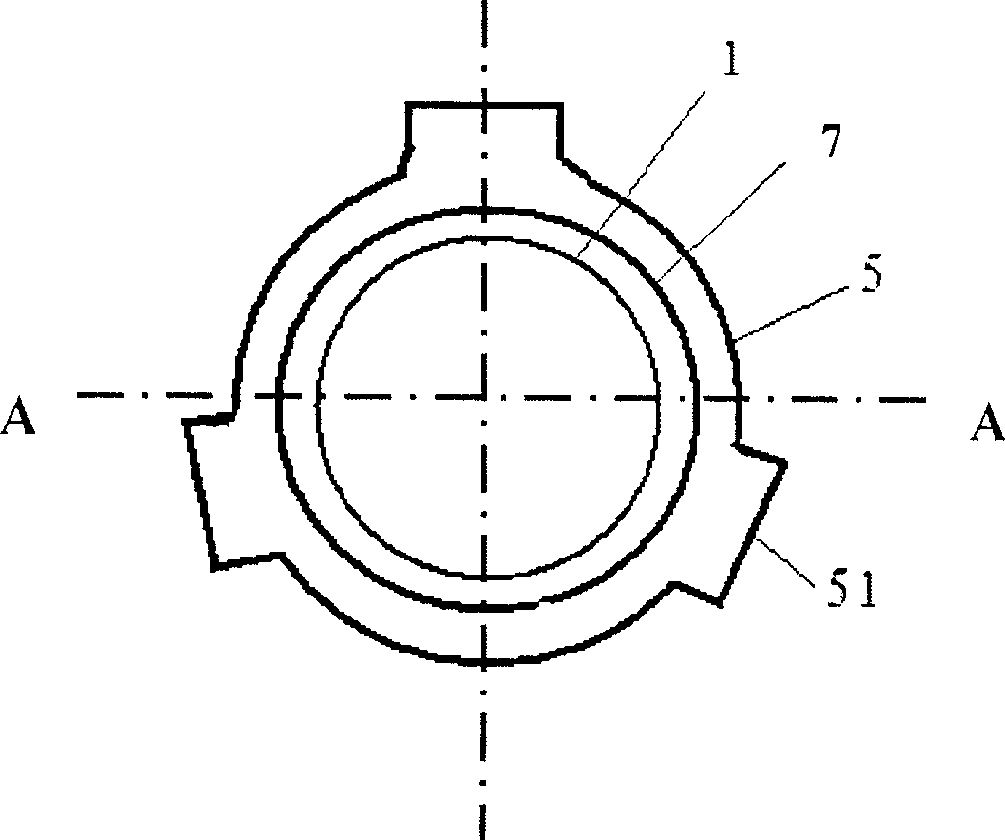

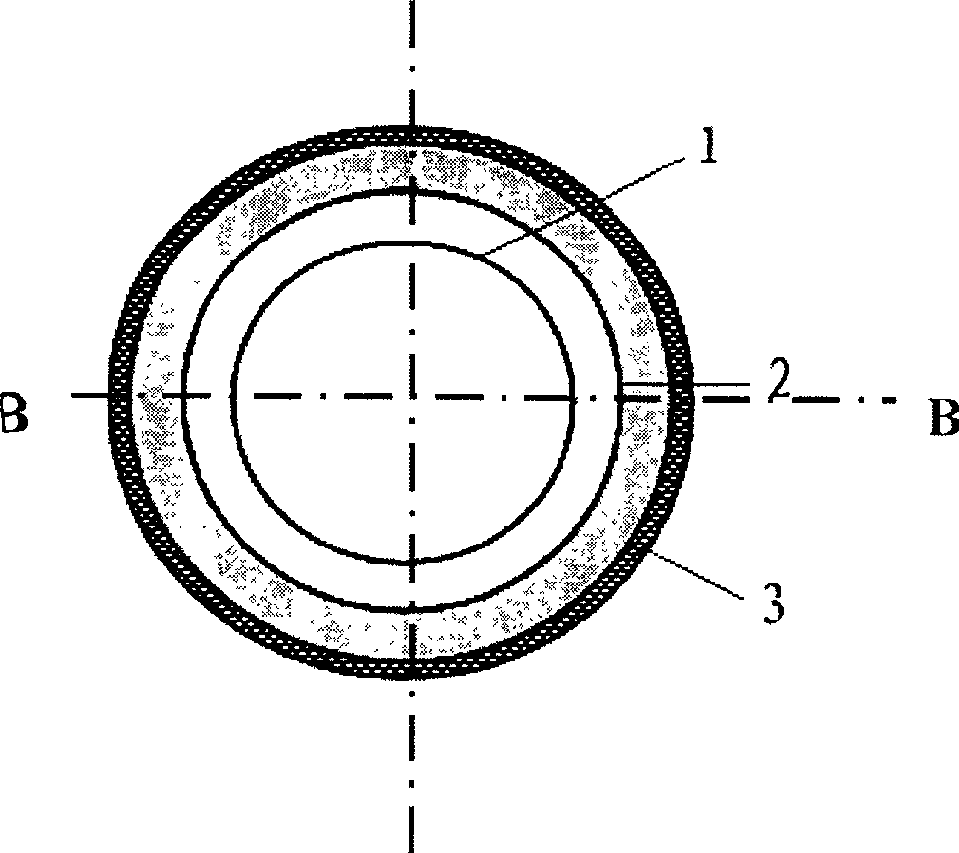

[0012] Self-proclaimed compensating oil pumping centralizing device of the present invention such as figure 1 As shown, the lower part of the boss 11 of the sucker rod 1 is connected to the collar 7 with an external thread, and a retaining ring 4 is clamped between the boss 11 and the collar 7, and then it is covered by the centralizing sleeve 5; the middle of the retaining ring 4 has A depressing tongue 41 protruding inward, the inner wall of the righting sleeve 5 is provided with a ring groove for the ring body 42 of the gear ring and the depressing tongue 41 to be inserted, and the depressing tongue 41 is tightly pressed by the boss 11 and the collar 7, so that the righting The sleeve 5 is connected with the sucker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com