Stapler

A stapler and staple technology, which is applied in the direction of binding, manufacturing tools, nailing staple tools, etc., can solve the problems of power reduction of the driving device, unreliable starting, difficulty in resetting to its resting position, etc., and achieve low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

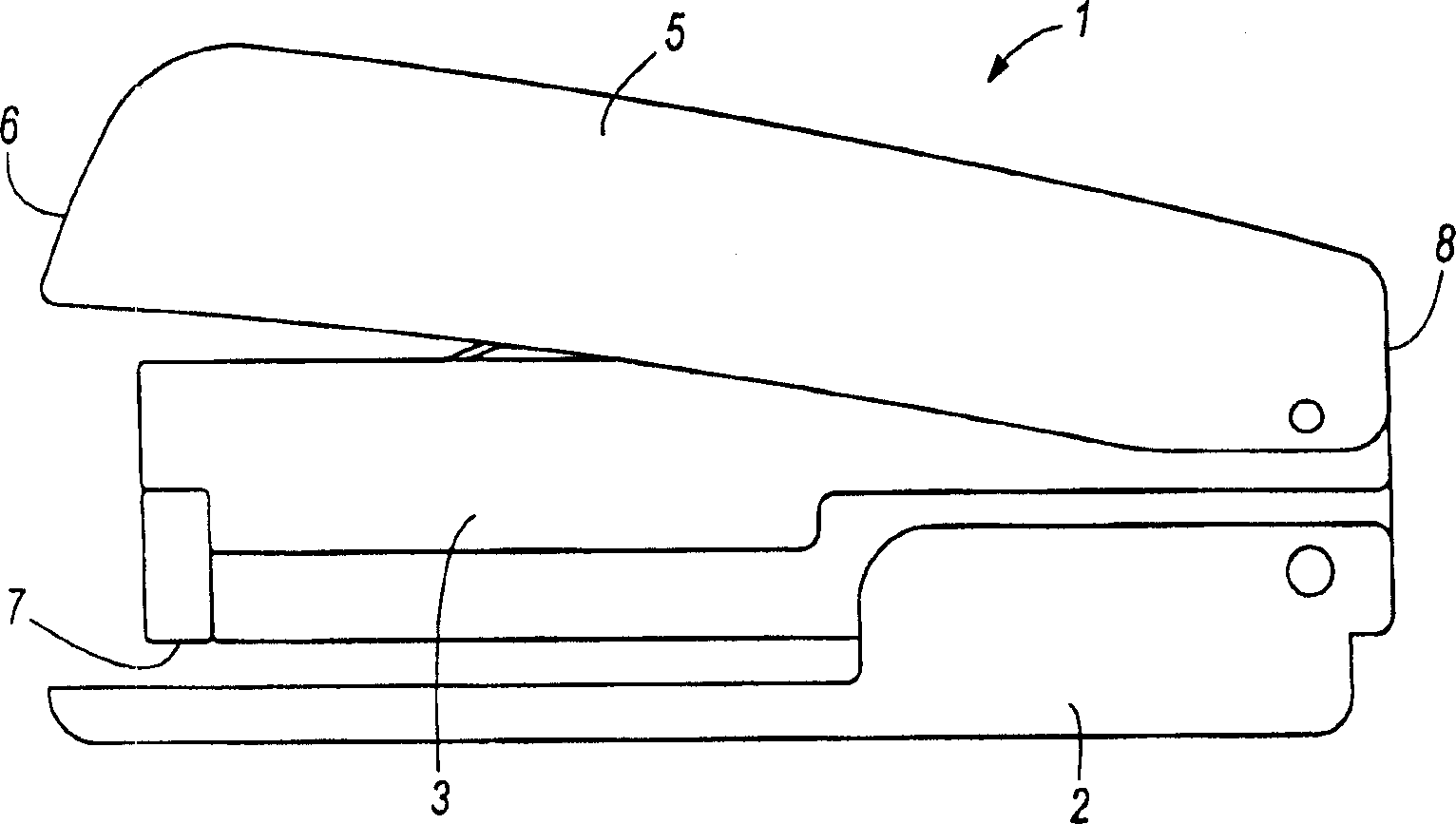

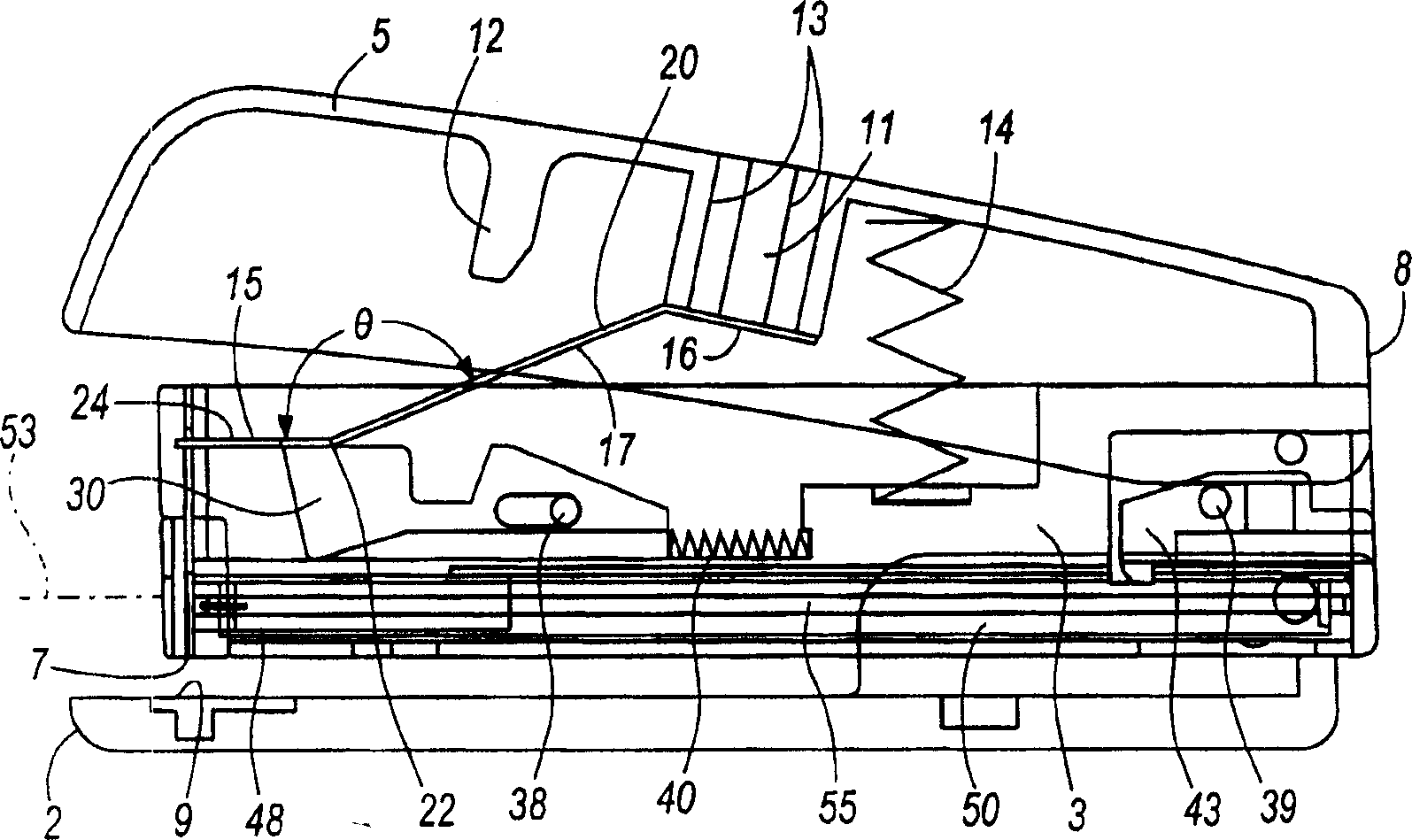

[0061] The first embodiment of the stapler 1 is shown in Figure 1-Figure 11 middle. The appearance of the stapler 1 is as follows figure 1 shown. refer to figure 1 and figure 2 , the stapler 1 defines a front end 6 close to the staple ejection position 7 and a rear end 8 opposite to the front end 6 . The stapler 1 comprises a base 2 , a frame 3 attached to the base 2 and a handle or cover 5 attached to the frame 3 near the rear end 8 of the stapler 1 .

[0062] The base 2 includes an anvil 9 . Those skilled in the art will appreciate that the anvil 9 facilitates clinching or bending of the staples. The base 2 supports the stapler 1 on a support surface such as a desk, a table, a countertop, and the like.

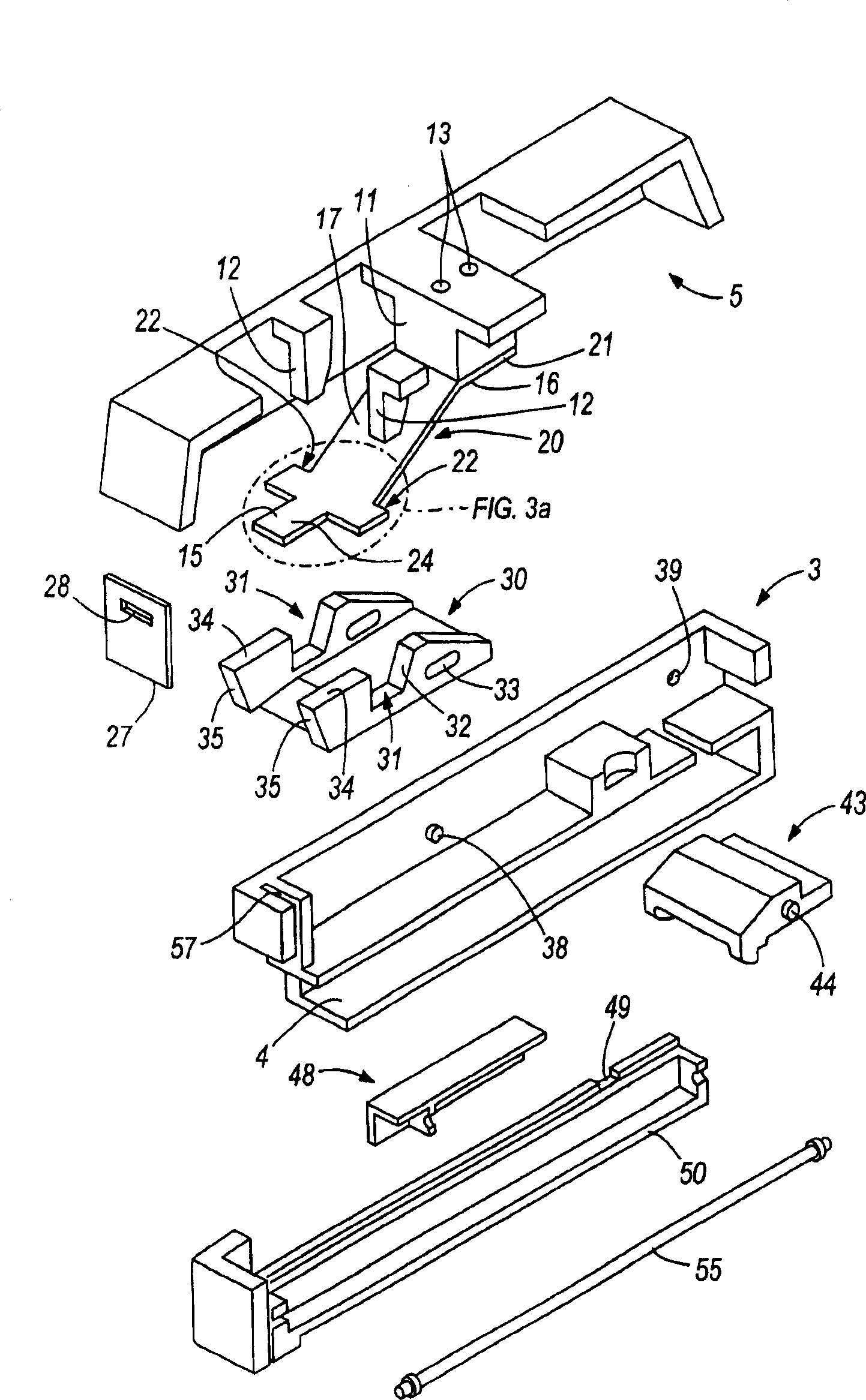

[0063] figure 2 The internal configuration of the stapler 1 is shown when the stapler 1 is not in operation. image 3 is an exploded view showing several components of the stapler 1 . For clarity, image 3 is a cross-sectional view along the longitudinal axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com