QTi3.5-10 graphite semi-solid size mechanical stirring producing method

A semi-solid slurry, mechanical stirring technology, applied in mechanical equipment, stirring device, lighting and heating equipment, etc., can solve the problem of inability to directly prepare graphite semi-solid slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

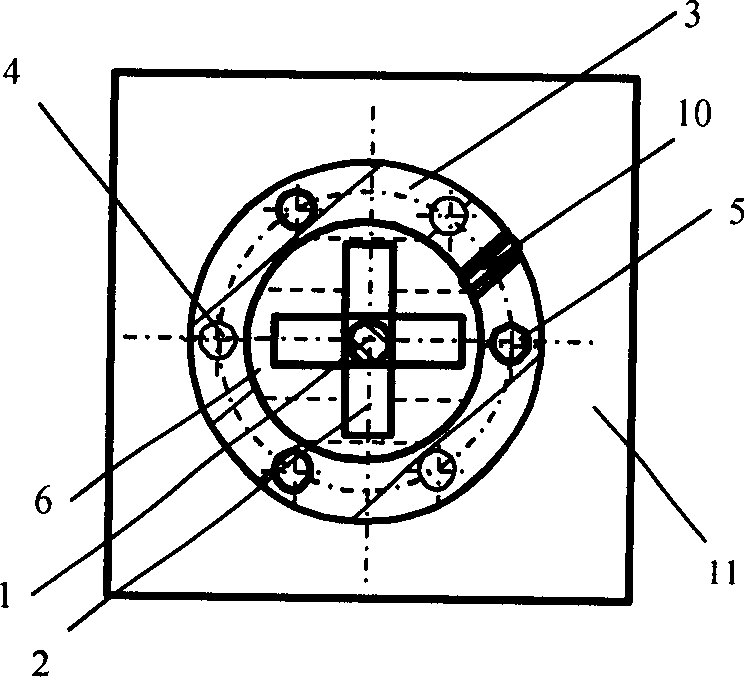

[0023] In conjunction with accompanying drawing, the specific description of the inventive method to prepare QTi3.5-10 graphite semi-solid slurry device is as follows:

[0024] The mechanical stirring preparation device of QTi3.5-10 graphite semi-solid slurry is mainly composed of a mechanical stirrer and its drive and up and down movement control device, graphite crucible 3, upper cover 8, plug 7, Ar gas pipe 9 and thermocouple 10.

[0025] The graphite crucible 3 is fixed on the base frame 11 by means of mechanical connection, and the heating pipe 4 and the cooling pipe 5 are evenly distributed in the wall, and are respectively connected with the external power supply and the cooling liquid supply system.

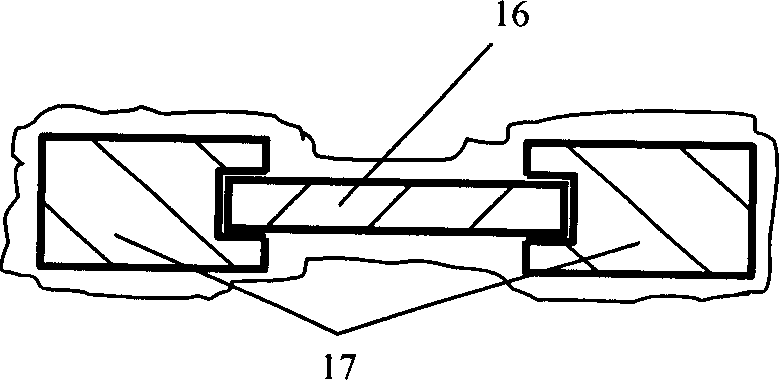

[0026] The mechanical stirrer is composed of a circular stirring rod 1 and four double-sided arc-shaped straight blades 2, and the material is heat-resistant ceramics; the lower end of the circular stirring rod 1 is square, and its four sides are tangent to the circular st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com