Production of ventilating, antiflame, oilproof, waterproof, acidproof, and antinear-infrared dacron tarpaulin

A vapor-permeable, near-infrared technology, which is applied in the field of preparation of vapor-permeable flame-retardant, oil-proof, water-proof, acid-proof, and near-infrared polyester tarpaulins. Insufficient performance and other problems, to achieve the effect of increased protection function, excellent flame retardant and washable resistance, and excellent flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

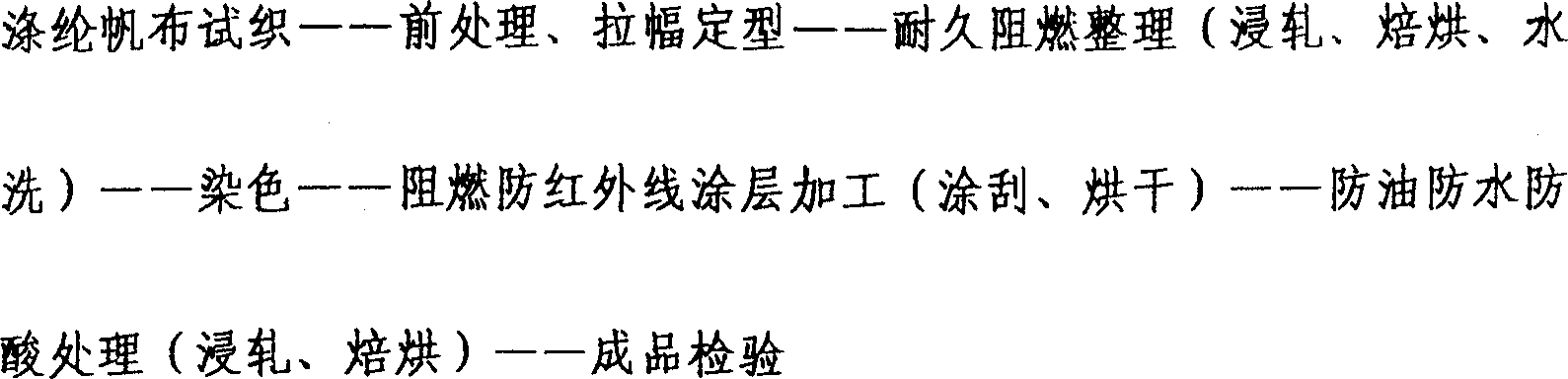

Method used

Image

Examples

Embodiment Construction

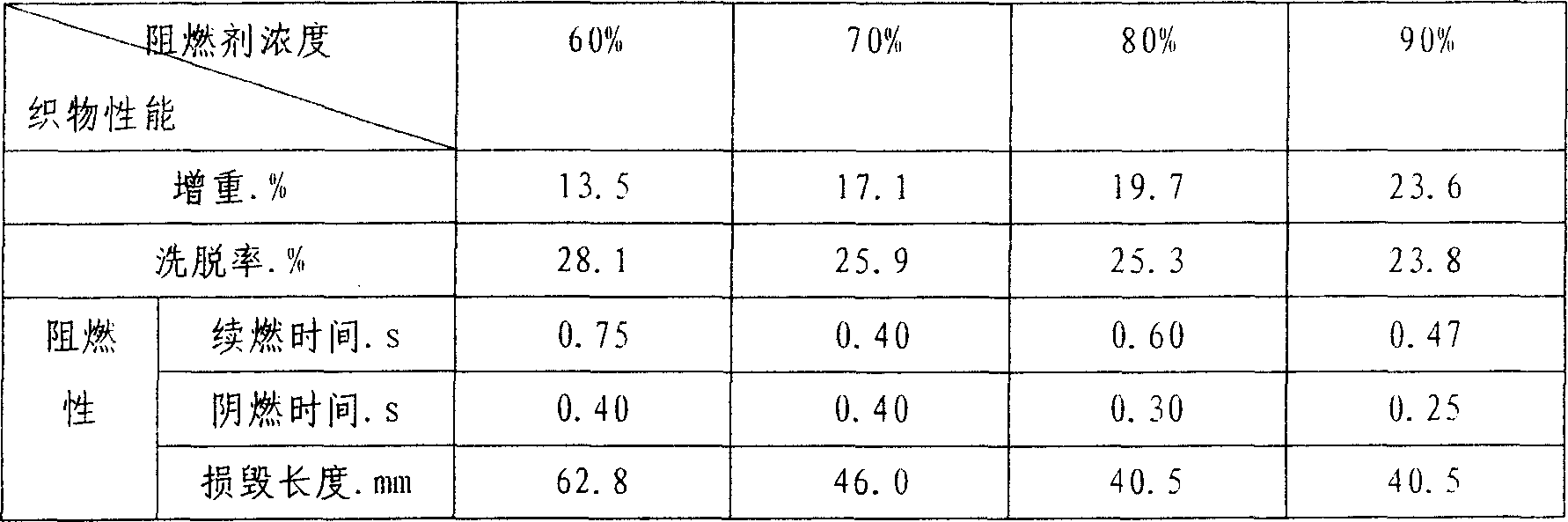

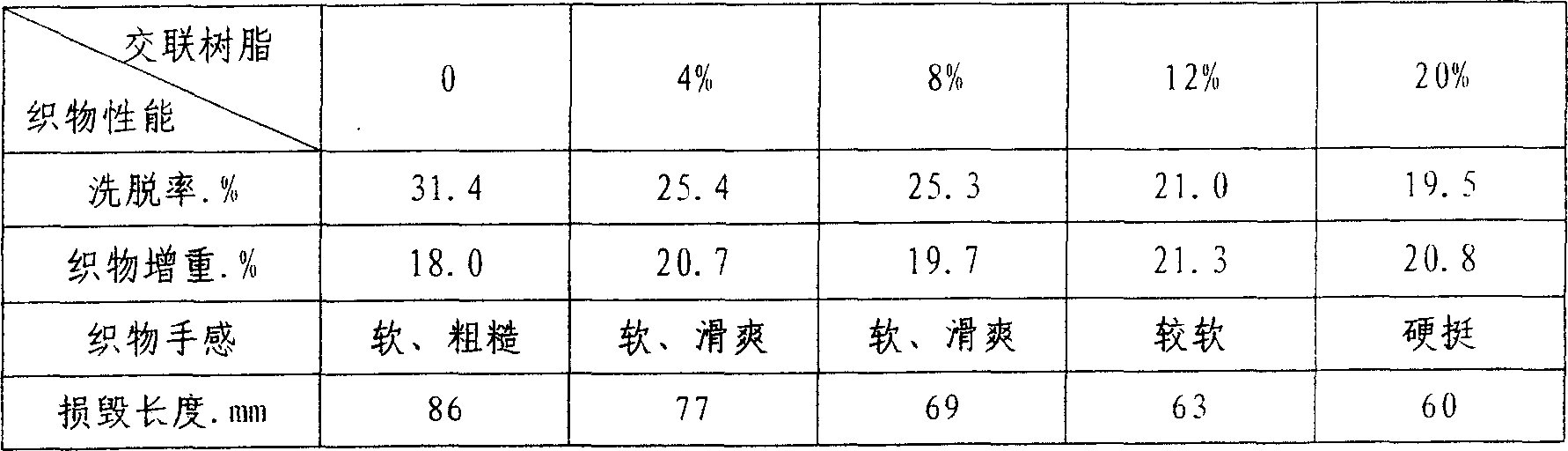

[0016] Vapor-permeable, flame-retardant, oil-proof, water-proof, acid-proof and near-infrared polyester tarpaulin is a multi-functional protective fabric with specified fiber materials. Its core protective function is flame retardancy and oil-proof, waterproof and acid-proof performance, and the flame-retardant processing is carried out in two steps (base fabric first and then coating). Phosphorus-halogen flame retardants are used for the durable flame-retardant finishing of the base fabric and the flame-retardant coating, and fluorine-containing compounds are used for the oil-proof, waterproof and acid-proof treatment, so that the phosphorus-halogen flame retardant and the fluorine-containing acid-proof agent have the same synergistic effect . The solution of vapor permeability (wetness) depends on the modification of PU coating resin and one-sided coating. The near-infrared protection is to add suitable dyes to the PU coating slurry, and make a reasonable formulation of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com