Stroke control device

A technology of stroke control and pressure release, which is applied in the direction of manufacturing tools, metal processing, presses, etc., can solve the problems of loss of control of the stroke switch, failure to prevent the rotation deviation of the piston rod, etc., and achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

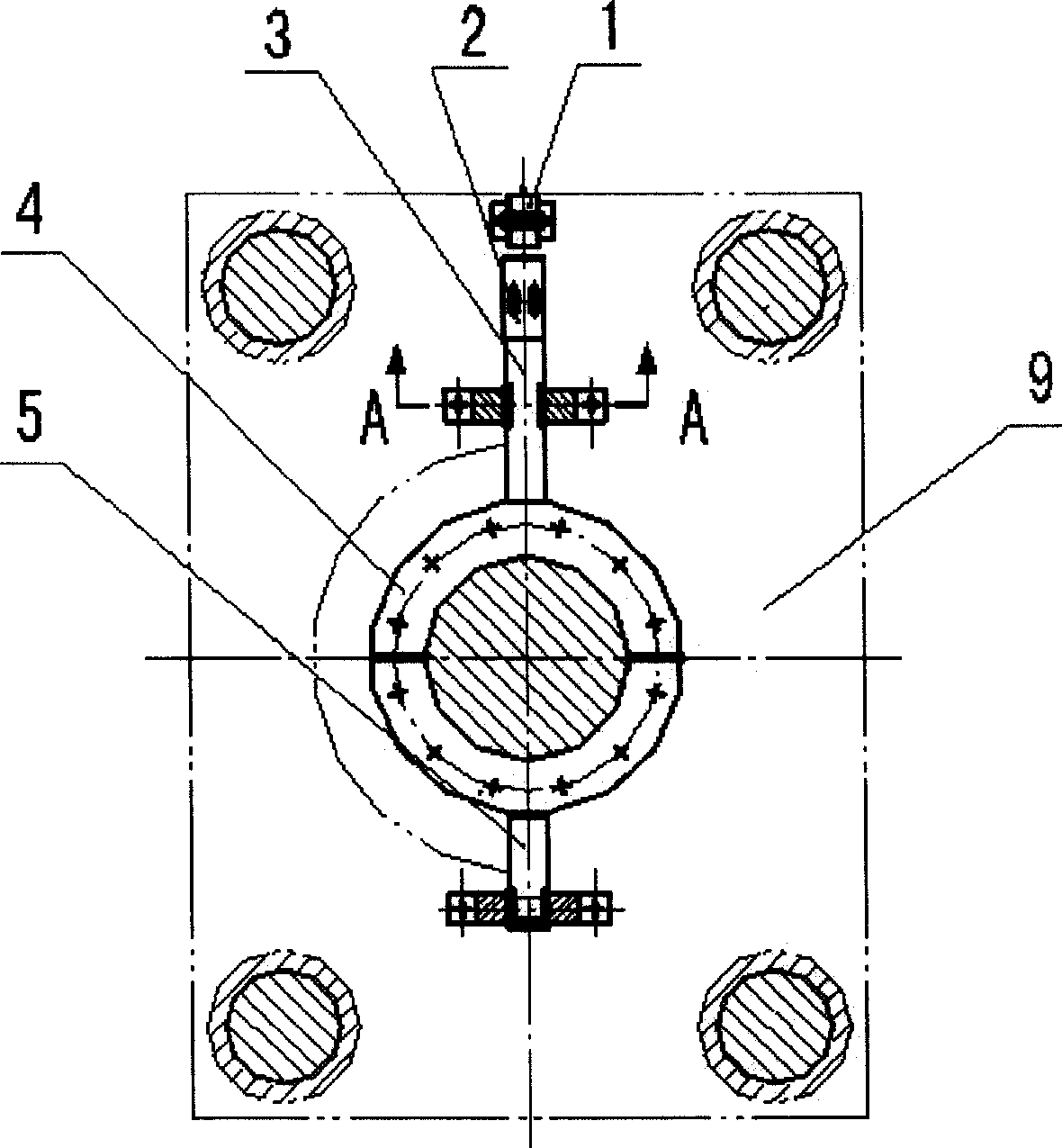

[0017] Embodiment of the present invention: connect according to the diagram. First, connect the proximity switch 1 to the fixing plate 9; secondly, fix the flange 4 on the top surface of the piston rod of the pressure release cylinder with bolts, and weld the torsion arm 3 and the torsion arm 5 on both sides of the flange 4. Connect the induction plate 2 with bolts on the top of 3, and adjust the distance from the proximity switch 1 by using the oblong hole on the induction plate 2; 7 and the connecting plate 8 are connected with countersunk head screws, and the inlays 6 on the torsion arm 3 and the torsion arm 5 are placed between the guide rails 7; finally, the connecting plate 8 and the fixing plate 9 can be connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com