Multifunctional gas capturing net

A multi-functional, gas technology, applied in the direction of weapon types, offensive equipment, etc., can solve the problems of inconvenient dark environment and night patrol use, large size, inconvenient to carry, etc., to save network space, long range, and easy to carry. and the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

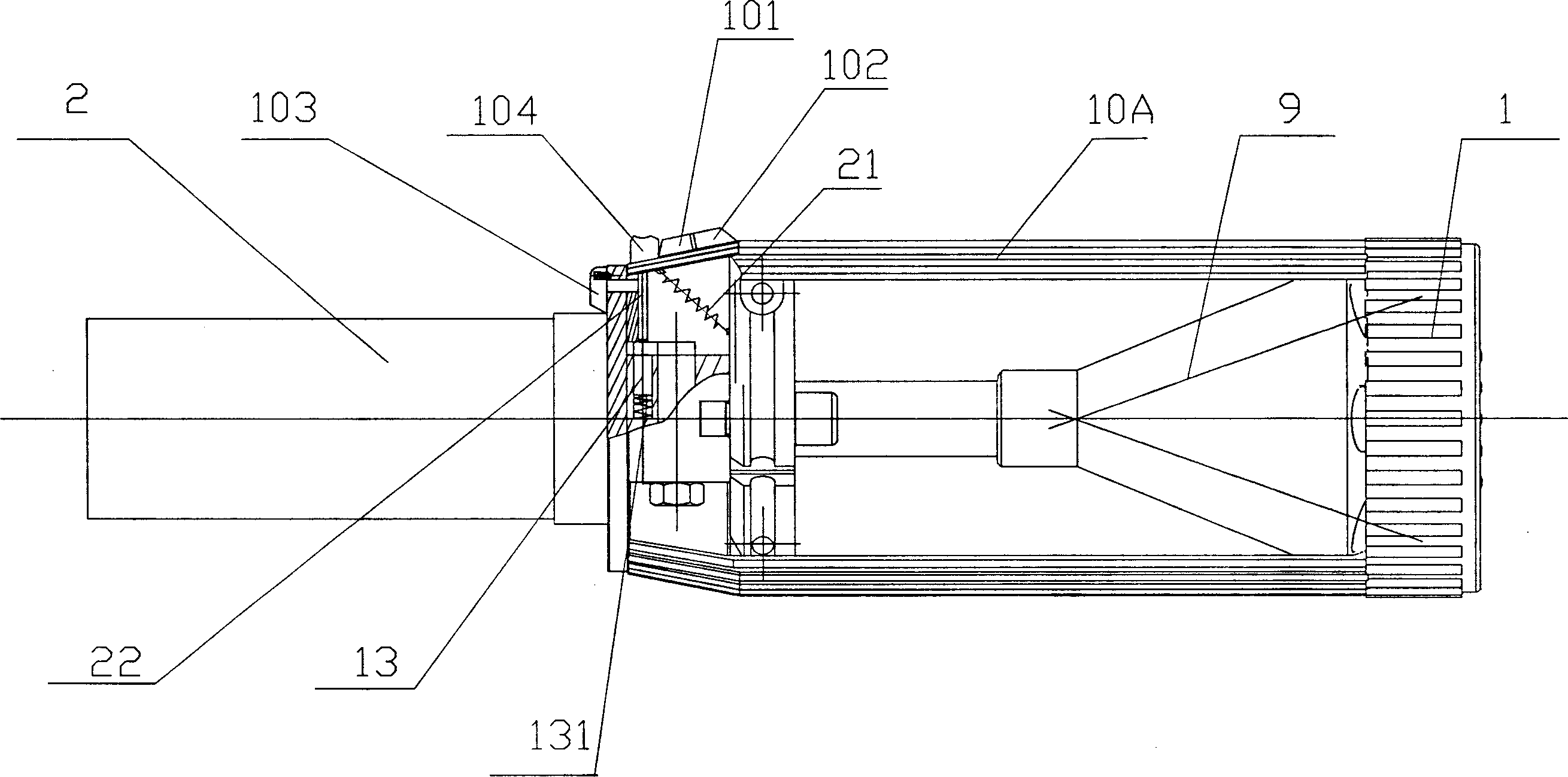

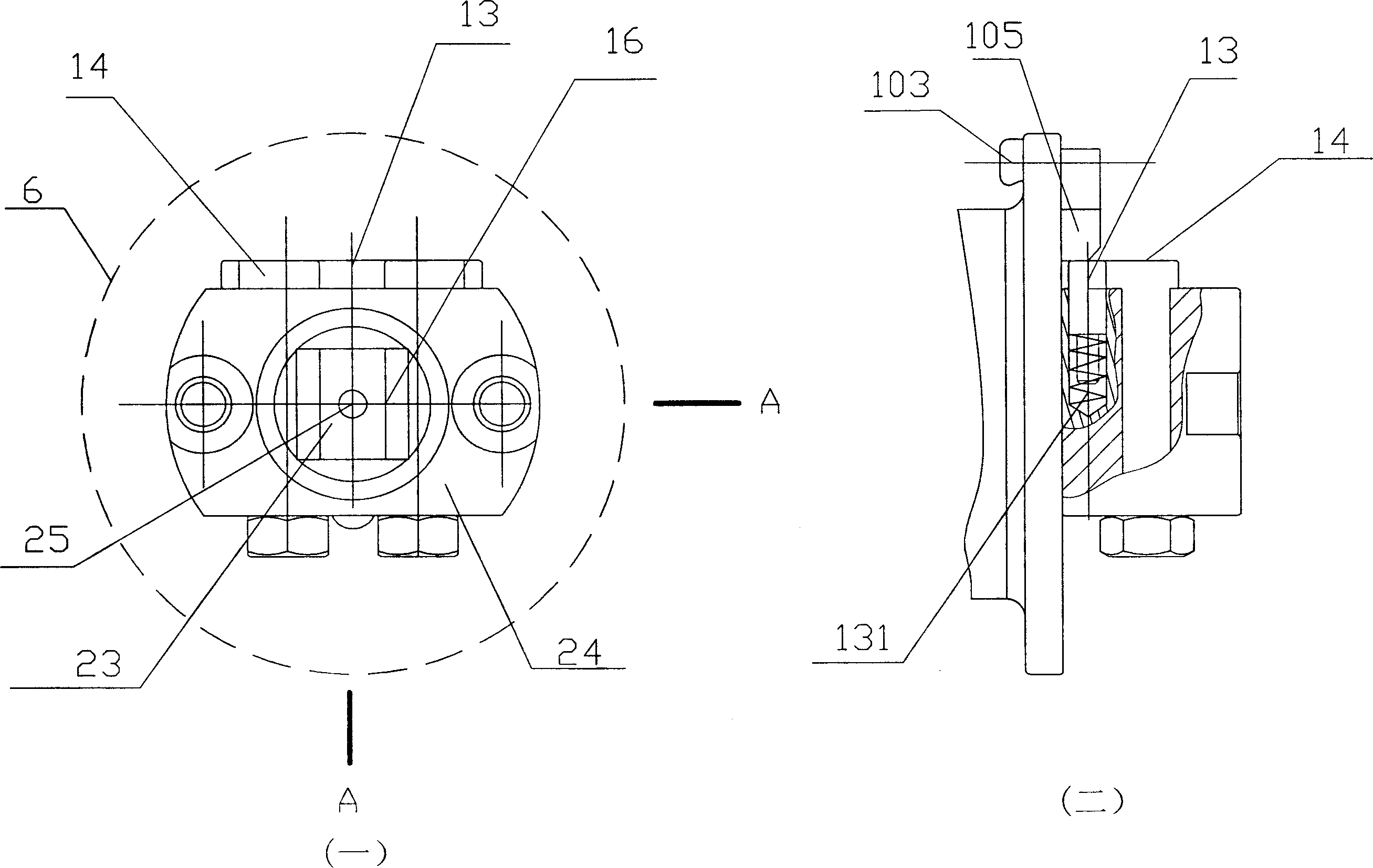

[0036] Implementation mode one: if Figures 1 to 4 Shown: the new multi-functional gas capture net of the present invention includes a top cover 1, a power source group 2 containing a gas storage bin 5 and a gas release mechanism 6, a capture net 4 with a traction head 3, an air guide tube 7, and a launch trajectory 8 The launching head group 9, wherein, the pulling head 3 is placed in the launching ballistic 8, one end of the air guide tube 7 communicates with the gas storage bin 5 through the gas release mechanism 6, and the other end communicates with the launching ballistic 9, and it also includes four hinged lower ends Evenly distributed fins 10 on the outer circumference of the power source group 1, the upper ends of the above-mentioned fins 10 are stuck in the annular flange 22 of the upper cover 1, and are gathered into a cylindrical shape; the air guide tube 7 is arranged on the four wings In the middle of the sheet 10, the catch net 4 is compressed between the fins 1...

Embodiment approach 2

[0041] Implementation mode two: if Figure 5 As shown: the opening structure is: the air guide tube 7 is covered with a push plate 208 that can slide on the air guide tube 7, a compression spring 202 is arranged between the push plate 208 and the power source group 2, and the push plate 208 The flap 10 can be pushed by the elastic steel sheet 209 . When the upper cover 2 draws the fins 10 together, the elastic steel sheet 209 on the fins 10 presses down the push plate 208 so that the compression spring 202 is compressed. When the upper cover 1 is released, the push plate 208 is pushed up under the action of the compression spring 202, and the elastic steel sheet 209 is driven to bounce the wings 10 open. The purpose of adopting the elastic steel sheet 209 is that after being loaded into the catch net, the elastic steel sheet 209 can be deformed so as not to affect the internal space of the wing. The structure of other components is as described in Embodiment 1.

Embodiment approach 3

[0042] Implementation mode three: if Image 6 As shown: the unfolded structure is: the wing 10 is equipped with a torsion spring 203 installed on the hinge shaft, and the two torsion arms of the torsion spring 203 act on the power source group 2 and the wing 10 respectively. When the wings 10 are closed, the torsion spring 203 is twisted; when the wings 10 are opened, the torsion spring 203 is released. The structure of other components is as described in Embodiment 1. When the pulling head 3 breaks away the upper cover 1, the torsion spring 203 bounces the wings 10 open.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com