Vacuum air-discharging system

A technology of vacuum exhaust and vacuum pump, applied in electrical components, circuits, liquid fuel engines, etc., can solve the problems of vacuum pump stop, reaction by-product mixing, affecting pump limit pressure, etc., to achieve the effect of improving efficiency and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Refer below Figure 1 to Figure 8 The embodiment of the vacuum exhaust system of the present invention will be described in detail. In addition, in Figure 1 to Figure 8 In the above, the same or equivalent constituent elements are given the same reference numerals to omit overlapping descriptions.

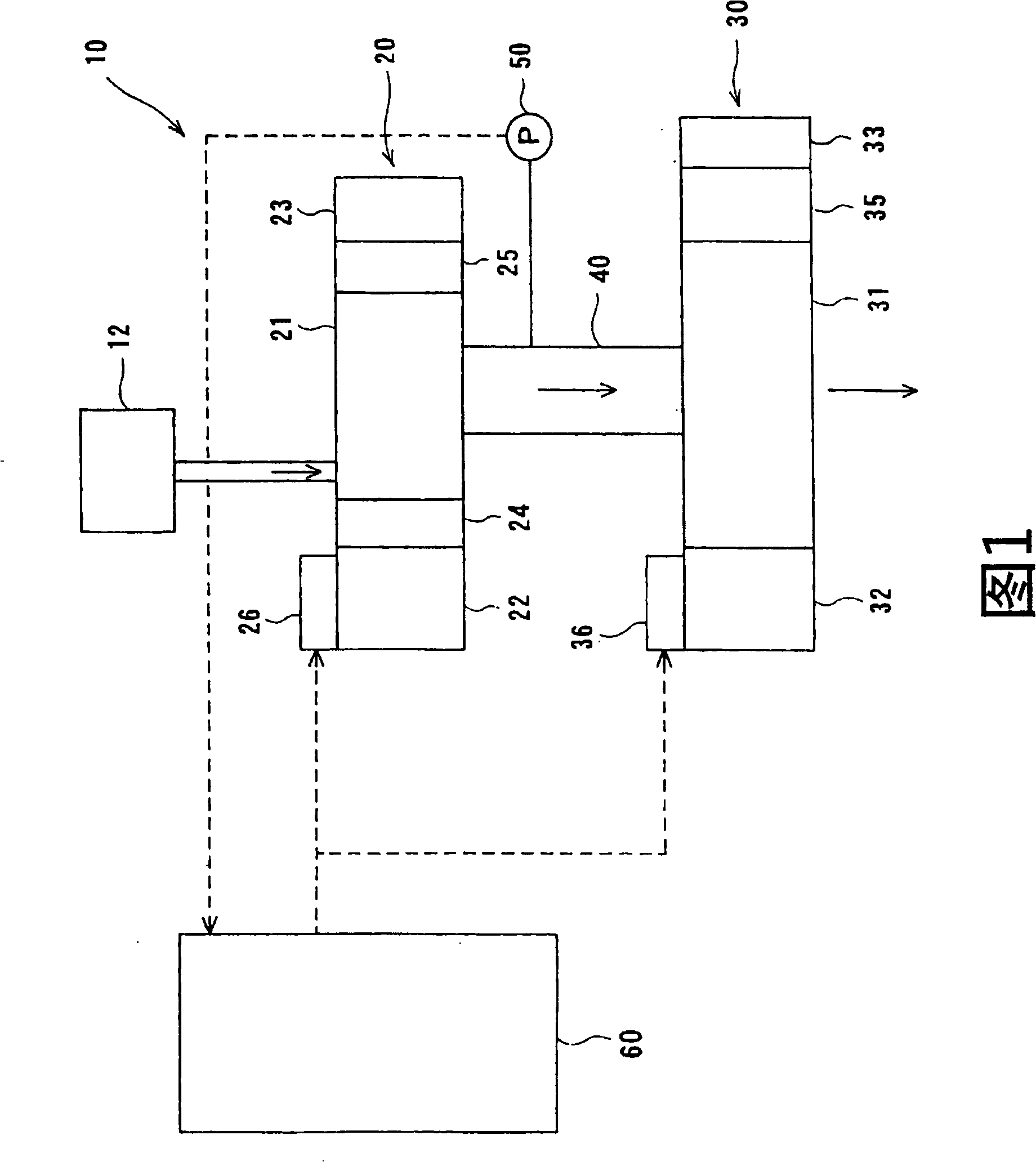

[0028] figure 1 It is a schematic diagram showing the vacuum exhaust system 10 of the first embodiment of the present invention. Such as figure 1 As shown, the vacuum exhaust system 10 is a system for exhausting a vacuum chamber 12 used in a semiconductor manufacturing process or a liquid crystal manufacturing process to a vacuum, and includes: two vacuum pumps 20 and 30; connecting the front vacuum pump 20 and the back stage The connecting pipe 40 of the vacuum pump 30; the pressure sensor 50 that detects the internal pressure of the connecting pipe 40; the control unit 60 that controls the vacuum pumps 20 and 30. The pressure sensor 50 detects the gas pressure in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com