Gasification cooling flue for steel-making converter

A technology for vaporizing cooling flue and steelmaking converter, which is applied in the manufacture of converters, etc., can solve the problems of increasing the workload of maintenance and slag cleaning, failing to achieve cooling flue gas, etc., so as to reduce the phenomenon of slagging and slagging, and prolong the service life. , the effect of improving labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

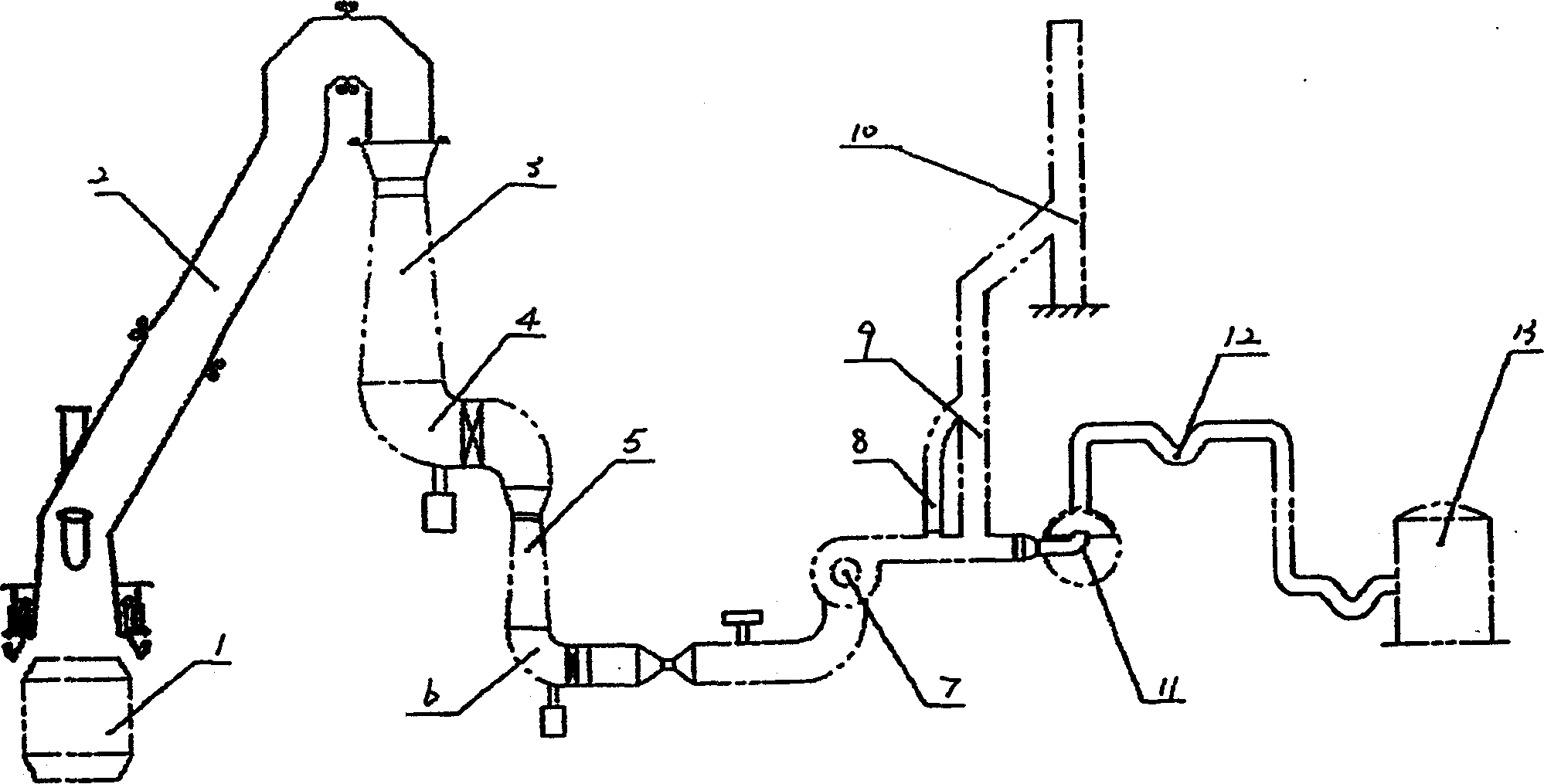

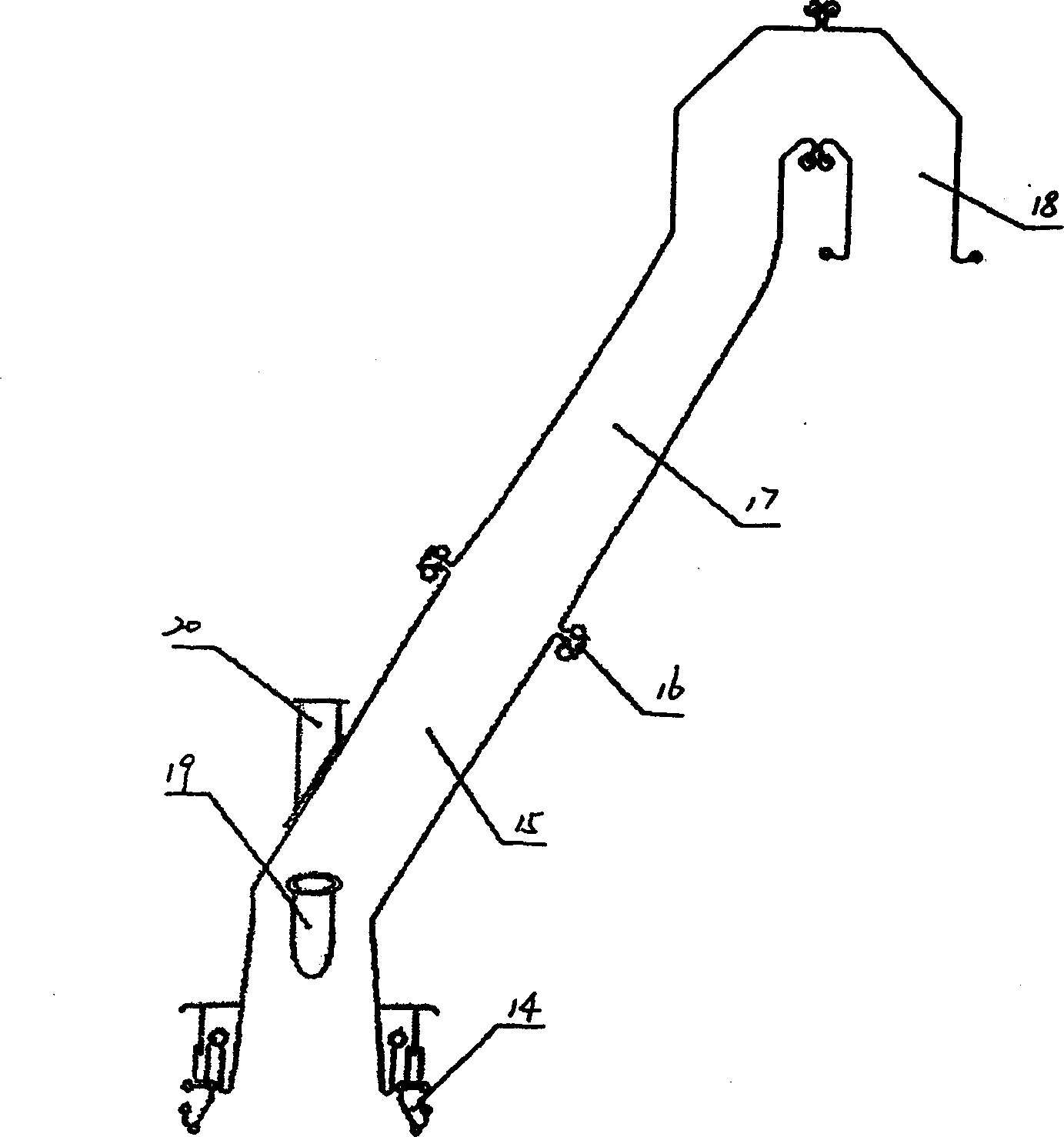

[0041] see figure 2 , The vaporization cooling flue used in the forced circulation steelmaking converter of the present invention is composed of a movable hood 14, a fixed section flue 15 at the furnace mouth, an intermediate section flue 17 and an end section flue 18. The movable fume hood 14 is placed above the converter, and the movable fume hood 14, the fixed section flue 15 at the furnace mouth, the middle section flue 17 and the final section flue 18 are sequentially connected.

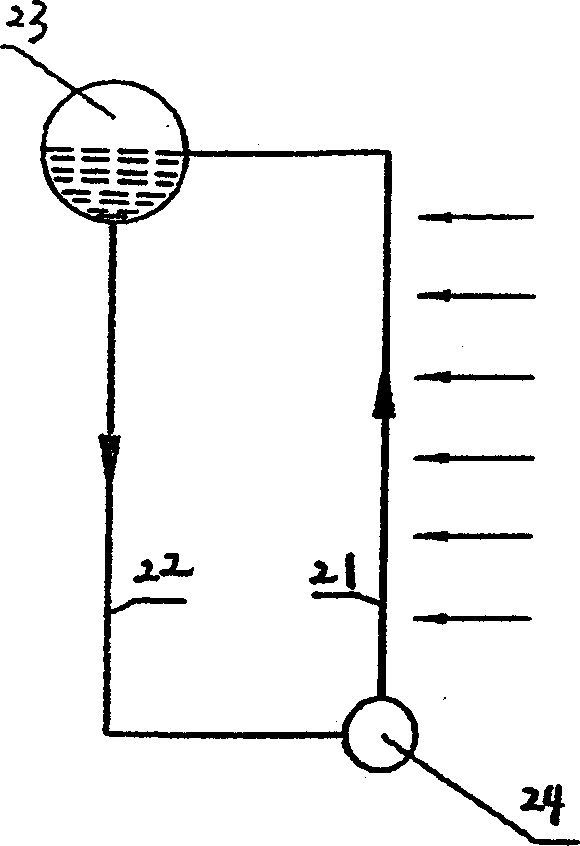

[0042] see Figure 6 A circulation pump 26 is added in the circulation loop between the movable fume hood 14 and the air bubble 23 of the fixed section flue 15 of the furnace mouth and the lower header 24.

[0043] see Figure 7 , Expansion joints 28 are used to connect between the flue 15 of the fixed section of the furnace mouth and the flue 17 of the middle section.

[0044] see Figure 8 , The connection between the middle section of the flue 17 and the end section of the flue 18 adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com