Method of conformal coating using noncontact dispensing

A non-contact, conformal coating technology, applied in the direction of coating non-metallic protective layer, coating, printed circuit coating, etc., can solve the problem that the auxiliary droplet is outside the target area and is difficult to control, so as to save materials and reduce Maintenance cost, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

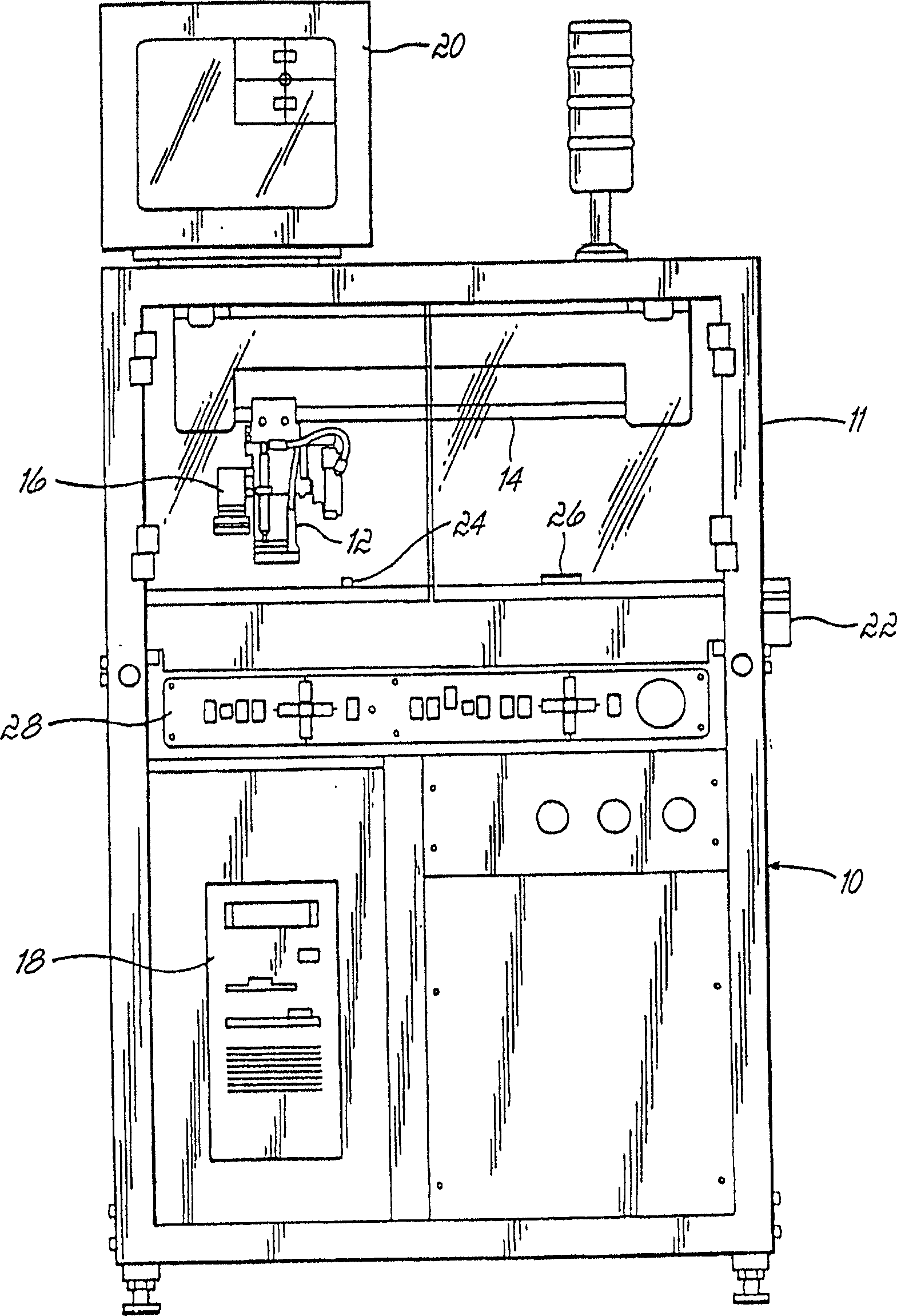

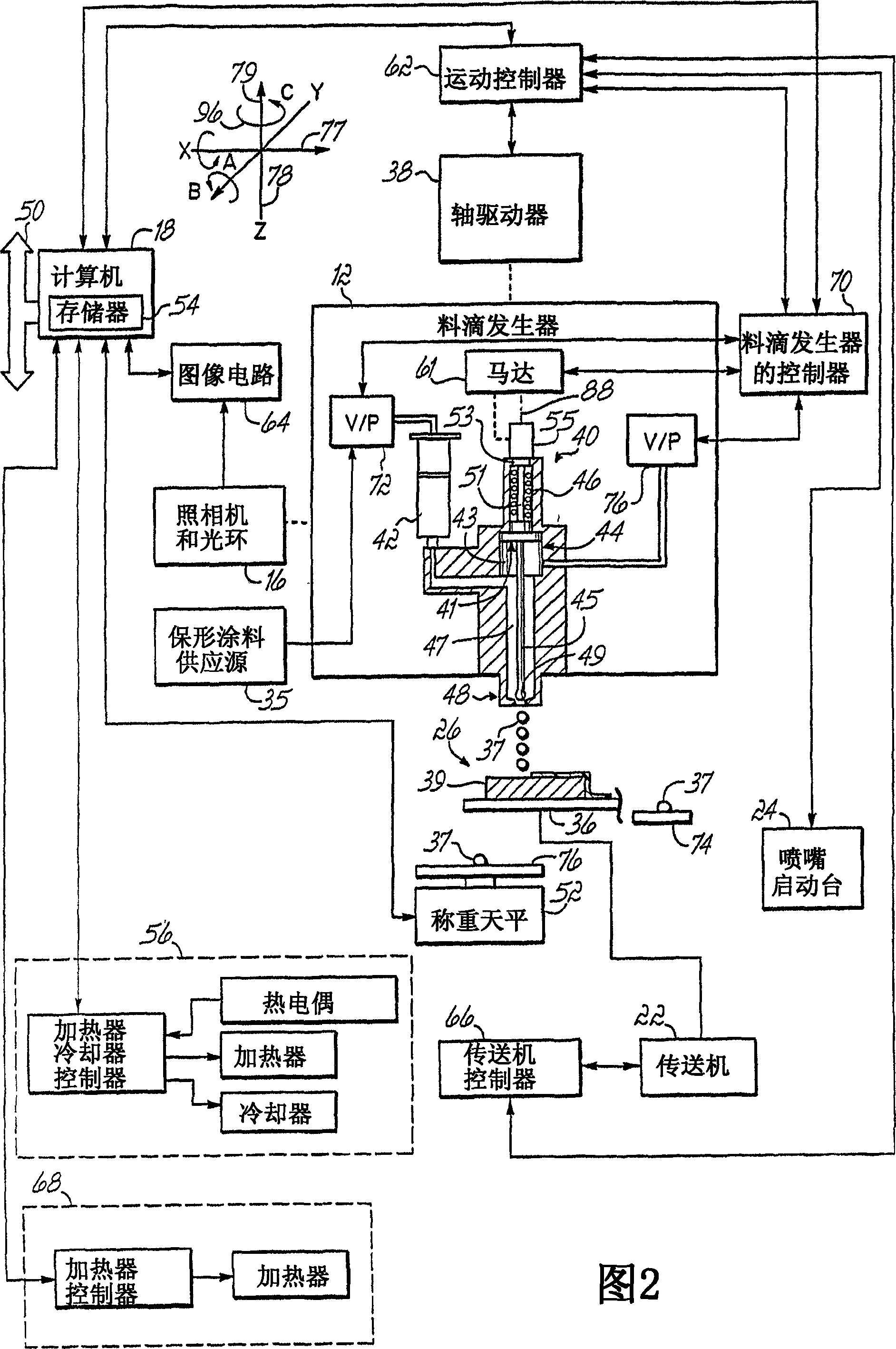

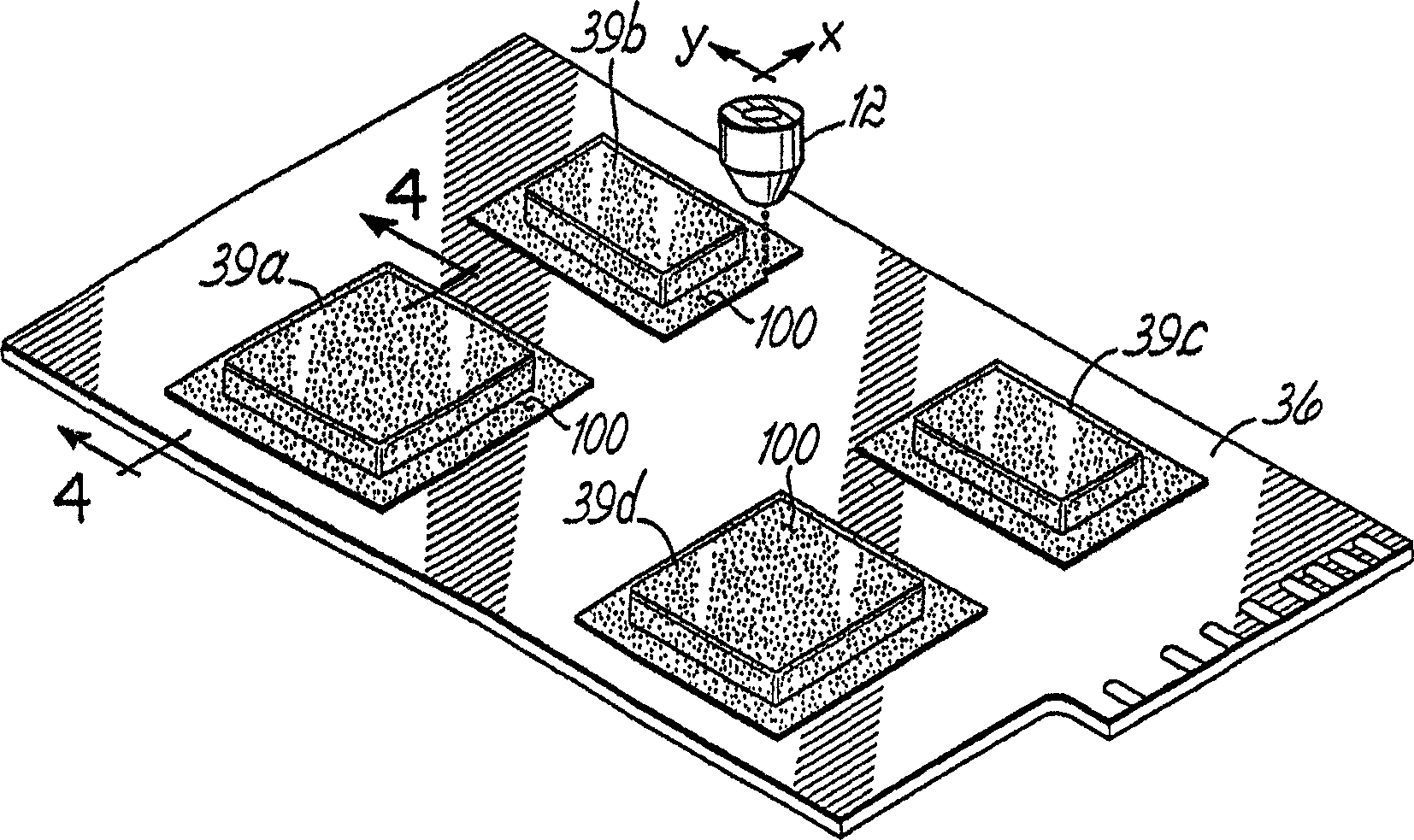

[0016] figure 1 It is a schematic diagram of a computer-controlled non-contact adhesive material injection system 10, such as the "AXIOM" X-1020 series available from Asymtek of Carlsbad, California, USA. The gob generator 12 is mounted on a Z-axis drive which is suspended from the X, Y positioning device 14 in a known manner. The X and Y positioning devices 14 are mounted on the frame 11 and define the first and second non-parallel axes of movement. The X, Y positioning device includes a cable driver combined with a pair of independent controllable stepping motors (not shown) in a known manner. A camera and a light-emitting diode (LED) light ring assembly 16 is connected to the gob generator 12 for movement along the X, Y, and Z axes to detect points and locate reference points. The type of camera and light ring assembly 16 may be as described in US Patent No. 5,052,338 entitled "APPARATUS FOR DISPENSING VISCOUS MATERIALS ACONSTANT HEIGHT ABOVE A WORKPIECE SURFACE", and the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com