Method for manufacturing gear wheel in large diameter

A processing method and large-diameter technology, which can be applied to components with teeth, metal processing equipment, gear tooth manufacturing devices, etc., can solve the problems of high processing cost, difficult to find equipment, and processing difficulty, and achieve the purpose of reducing processing costs and saving energy. The effect of removing processing equipment and increasing carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

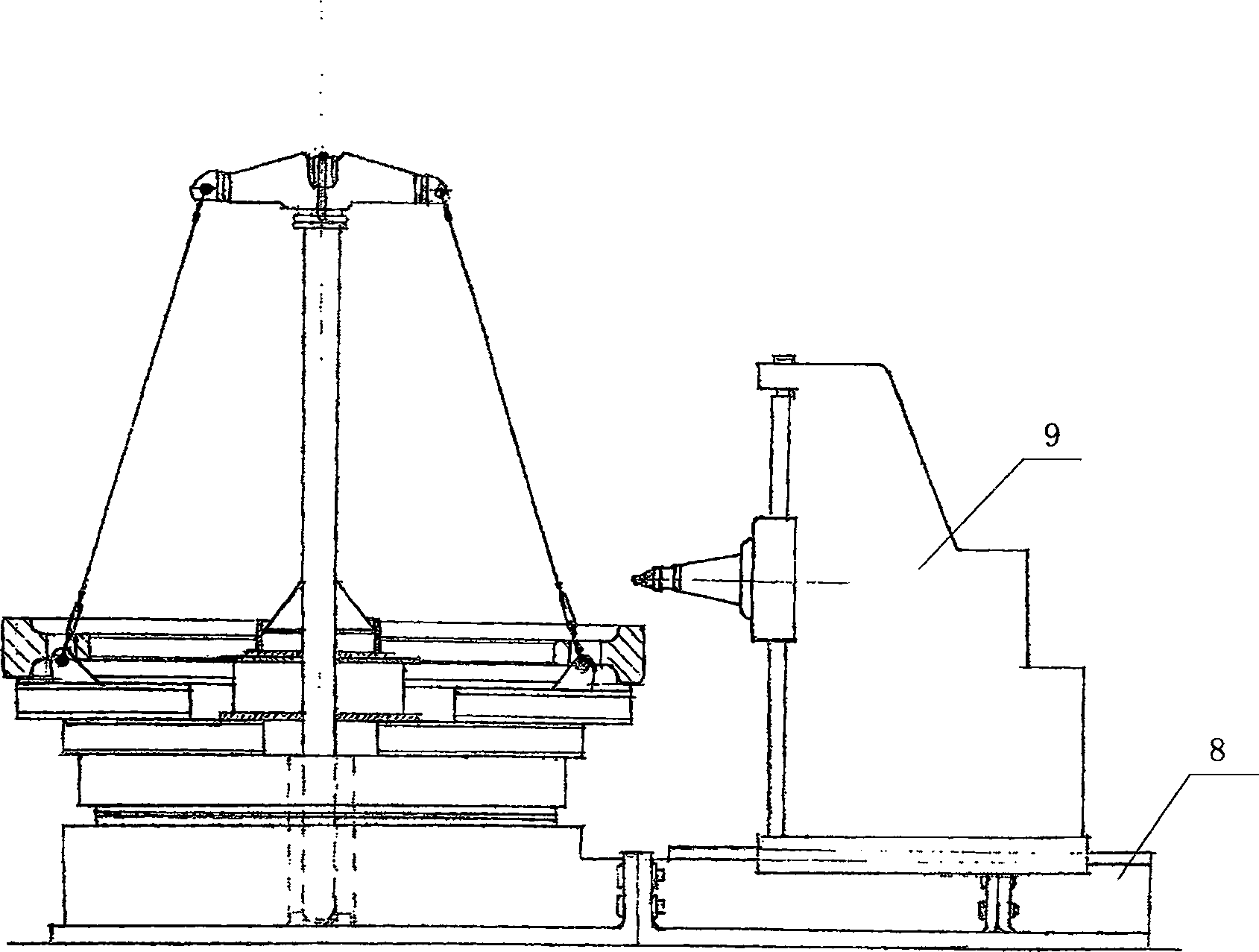

[0019] figure 1 Shown is the structure of the device used in the processing method of a large-diameter gear of the present invention. It includes a work table, guide rails 7 and a gear hobbing machine 8 .

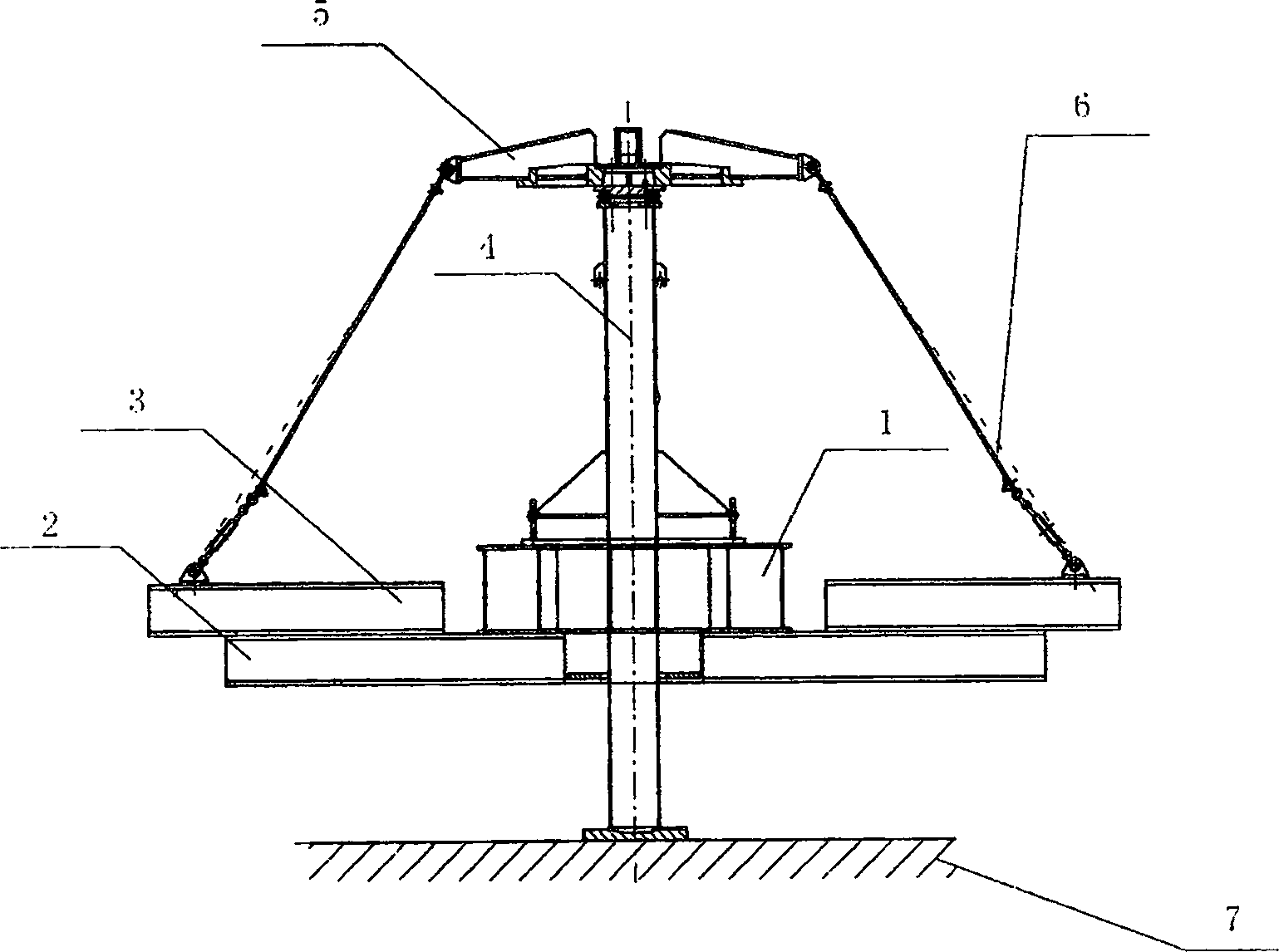

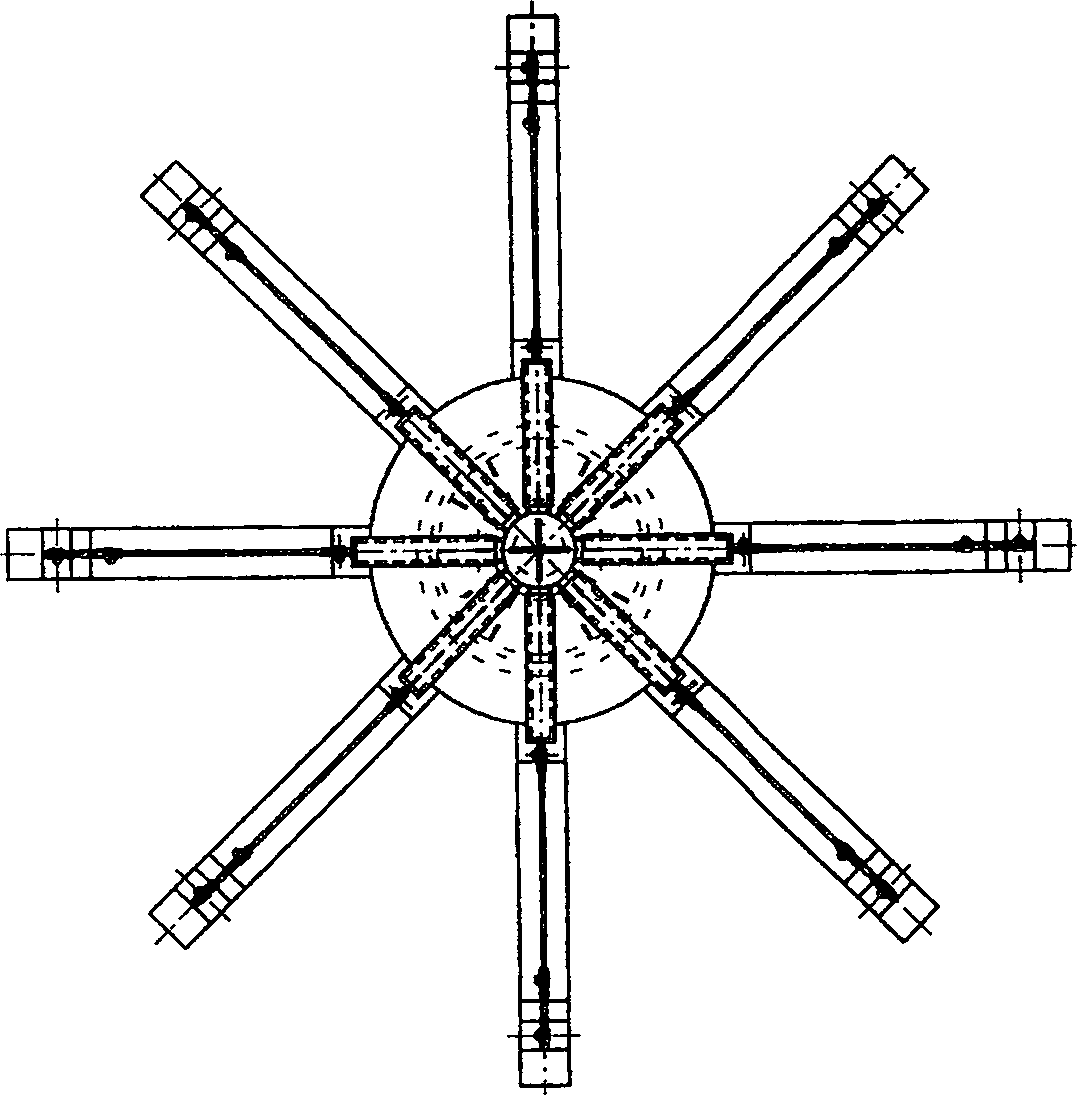

[0020] figure 2 Shown is a side view of the structure of the hobbing machine table top modified for use of the present invention. An extension beam is installed on the work surface 1, and the extension beam is divided into a first-level extension beam 2 and a second-level extension beam 3. The first-level extension beam 2 is directly installed on the work surface 1, and the second-level extension beam 3 is installed on the first-level extension beam 2. Above; the extension beam takes the center of the worktable 1 as the center of a circle and is radial with a uniform angle, such as image 3 Shown; Pole device 4 is vertically installed, and passes through the center of work surface 1, and its lower end acts on ground 7; Cable-stayed device comprises cable-stayed arm 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com