Mixing excitation permanent magnetic synchro generator

A permanent magnet synchronous and hybrid excitation technology, which is applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of large excitation current and motor electric excitation. Increased magnetic circuit reluctance, low motor efficiency, etc., to achieve the effect of small electric excitation loss, stable voltage output, and no risk of demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

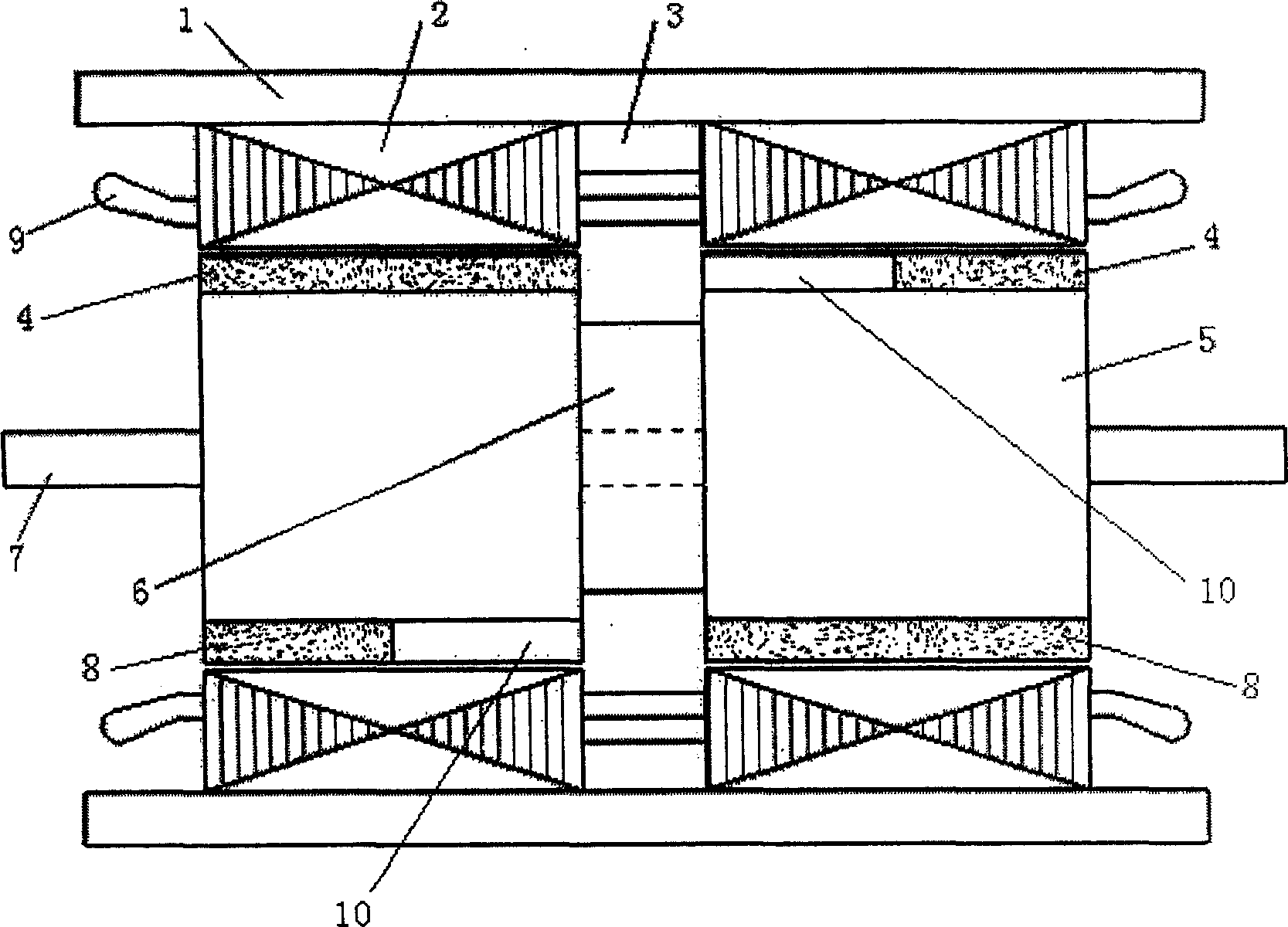

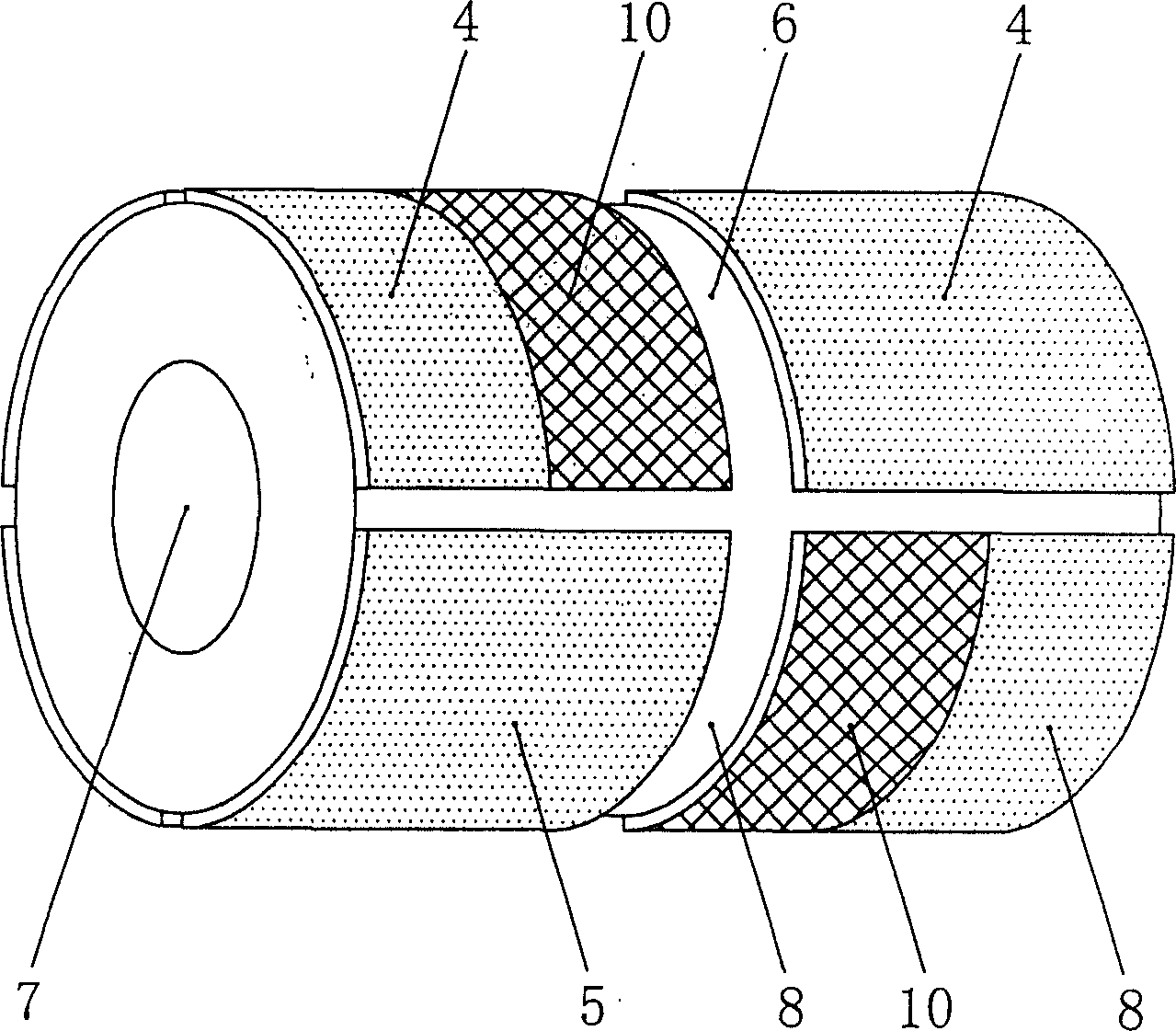

[0014] Example: such as figure 1 As shown, the structure of the present invention includes a housing 1, a stator core 2, a DC field winding 3, a rotor core 5, a rotating shaft 7, a stator armature winding 9 and a permanent magnet, and the stator core 2 is fixed on the housing along the axial direction of the housing , the rotor core 5 is placed on the rotating shaft 7 inside the stator core 2, supported by bearings and machine bases, the stator core 2 and the rotor core 5 are divided into two sections along the axial direction, and the segmented stator cores 2 are respectively connected to the housing 1 , and is connected mechanically and electromagnetically through the housing 1, a ring-shaped DC field winding 3 is placed between the segmented stator cores 2, and the stator armature winding 9 is a three-phase symmetrical winding, which is respectively placed in each segment of the stator core 2, a solid magnetic sleeve 6 is placed on the rotating shaft between the segmented r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com