Stretching device for flexible flat plate

A technology of stretching device and flat plate, applied in the direction of rotary printing machine, printing, printing machine, etc., to achieve high stretching efficiency, good stretching effect, and increase the effect of stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

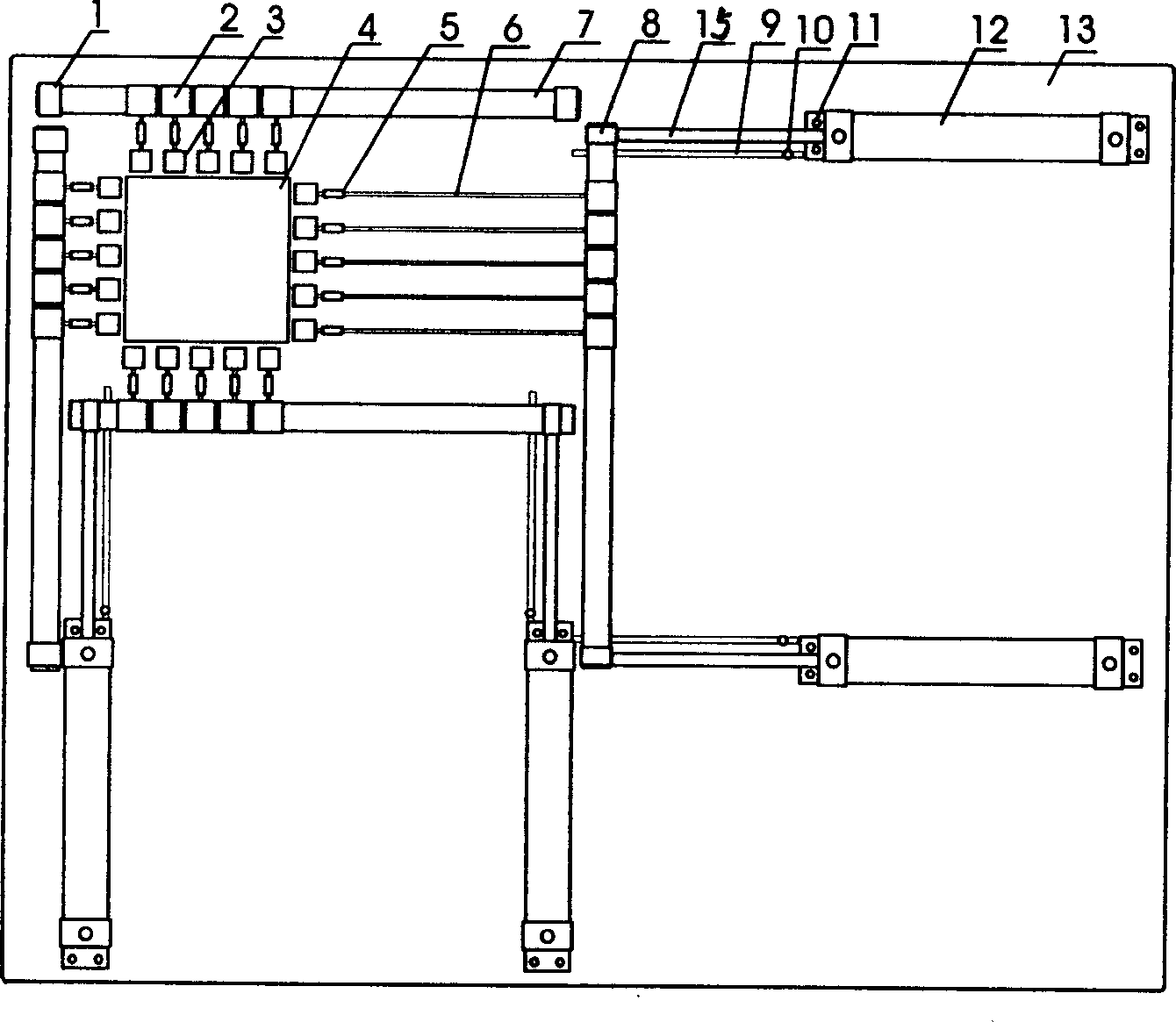

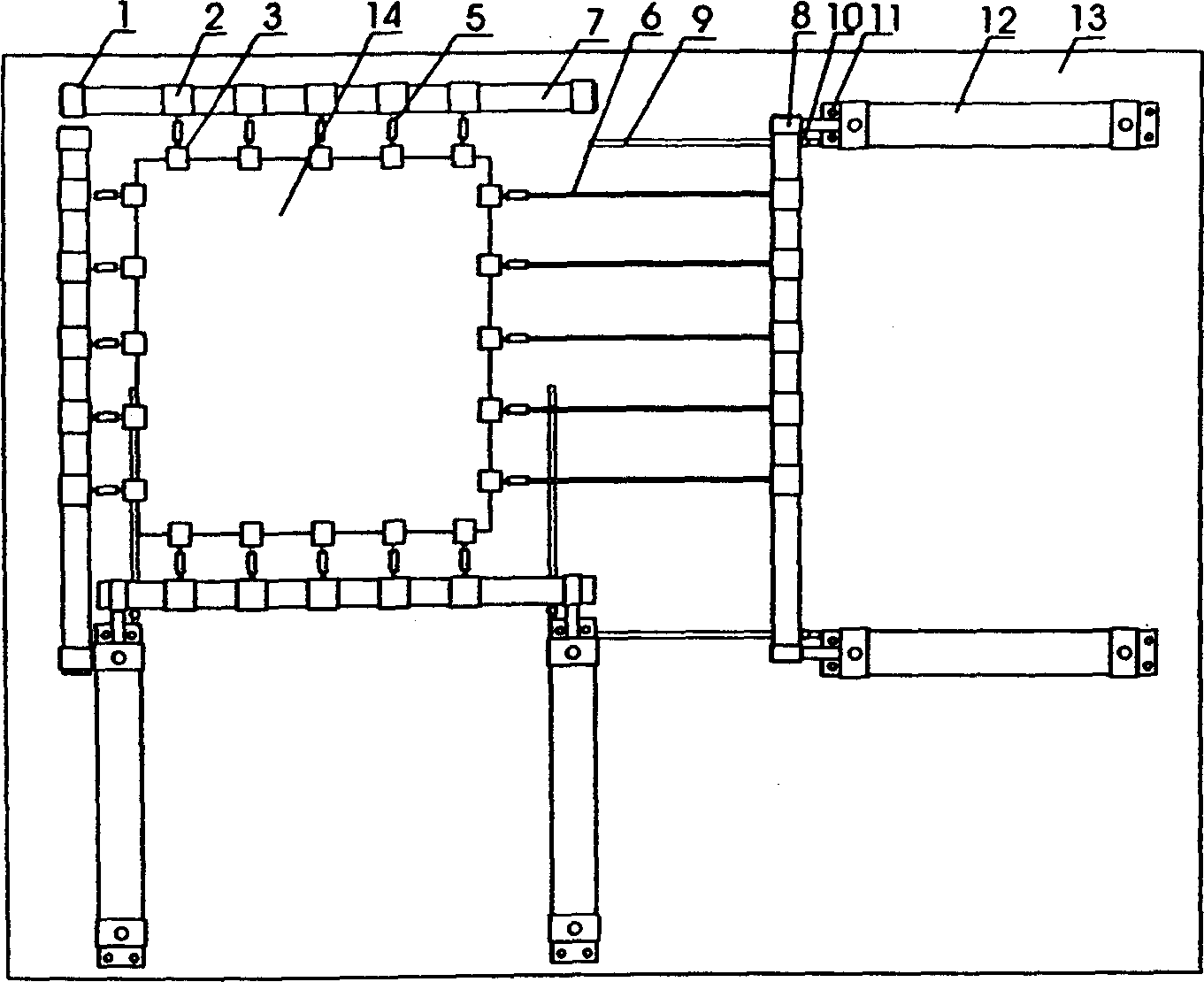

[0021] The above-mentioned structure of the present invention can be further illustrated by a non-limiting embodiment given in the accompanying drawings.

[0022] See attached Figure 1-2 , the bottom plate 13 of the flexible flat stretching device of this example is a high-density rectangular plate, 200 cm long, 120 cm wide, and 2 cm thick. Four metal guide rails 7 are distributed in a rectangular shape on the base plate 13, and the rail length is 75 centimeters, wherein two adjacent guide rails 7 are fixedly installed on the base plate 13 by the brackets 1 at both ends respectively, and the other two adjacent guide rails 7 are equipped with respectively The model of L-shaped support 11 fixing device on the base plate 13 is the cylinder 12 of SC40 * 350, and the piston rod 15 outer ends of cylinder 12 are connected with the terminations of these two adjacent guide rails 7 by molding connector 8 . One of the two guide rails 7 is connected with a stainless steel clamp 3 by a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com