A nitric oxides (NOX) waste pollution control in industrial process and resource reclaiming method

A technology for waste gas treatment and nitrogen oxides, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., to achieve good treatment effects, high investment ratio, saving space and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

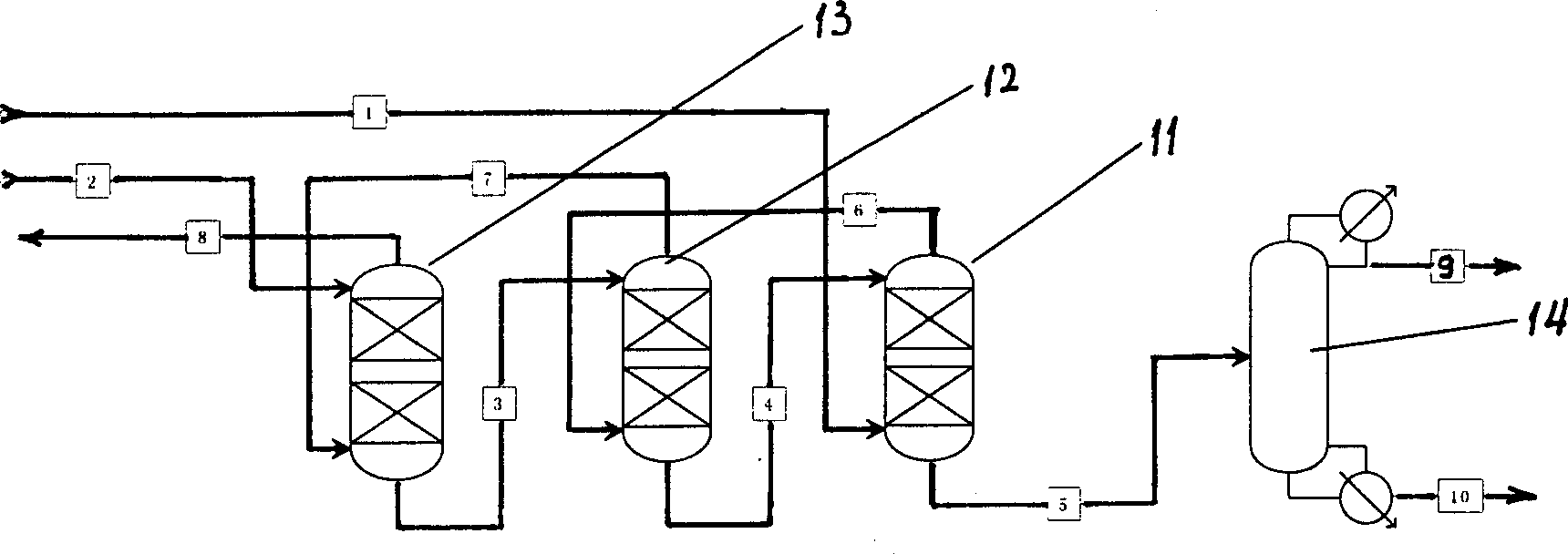

Embodiment 1

[0031] Embodiment 1: adopt 56% nitric acid to make oxidizing agent to produce organic acid product, produce NO X Exhaust gas, flow rate 4.6m 3 / h, NO X The volume concentration is 75%, where NO and NO 2 About 2:1. The exhaust gas and air are mixed according to the volume ratio of 1:4 and then enter the absorption section. The operating pressure of the absorption section is 2.6atm, and 6-stage absorption is adopted. Three towers are connected in series, and each tower has 2 stages, such as figure 1 shown. Each stage is equipped with liquid distributor, stainless steel filler 3m, liquid collection box and other accessories. 6 levels of liquid circulation are 5m 3 / h. The diameter of the absorption tower is 0.4m. NO in exhaust gas X The emission concentration is 22ppm, and the rate is 0.12kg / h. Nitric acid (yellow-green) with a mass concentration of 48% flows out from the absorption section, and enters the enrichment tower with a diameter of 0.6m, a 12-layer sieve tray t...

Embodiment 2

[0032] Embodiment 2: Adopt the concentrated nitric acid of 62% to make oxidant to produce methanol catalyst, produce NO and NO 2 Gas, the ratio is about 1:1, the flow rate is 10.2m 3 / h. The exhaust gas and air are mixed according to the volume ratio of 1:3.5 and then enter the absorption section. The operating pressure of the absorption section is 4atm, and 4-stage absorption is adopted. Two towers are connected in series, and each tower has 2 stages. Each stage is equipped with a liquid distributor, stainless steel packing 4m, liquid collection box and other accessories, and the liquid circulation volume of the four stages is 80, 80, 55, 55m respectively 3 / h. The diameters of the absorption towers are respectively 0.6m and 0.4m. NO in exhaust gas X The emission concentration is 45ppm, and the rate is 0.2kg / h. Nitric acid with a mass concentration of 45% (yellow-green, dissolving part of NO) flows out from the absorption section X ), enter the enrichment section, the e...

Embodiment 3

[0033] Embodiment 3: adopt the concentrated nitric acid of 98% to make oxygenant to produce silver nitrate, produce NO 2 Gas, the flow rate is 32.50m3 / h. The waste gas and air are mixed at a volume ratio of 1:2.5 and then enter the absorption section. The operating pressure of the absorption section is 5 atm, and the absorbent is clean water. A single tower with 3 stages of absorption is adopted, with a tower diameter of 0.8m. Each stage is equipped with a liquid distributor, stainless steel packing 5m, liquid collection box and other accessories, and the liquid circulation volume of the three stages is 150m3 / h. NO in exhaust gas X The emission concentration is 32ppm, and the rate is 0.18kg / h. Nitric acid (colorless) with a mass concentration of 38% flows out from the absorption section, and enters the concentrated nitric acid flow process of this plant to produce 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com