Device for knurling bottom of cubic paper cup of paper cup formation machine

A technology for forming machines and paper cups, which is applied in the direction of envelope/bag manufacturing machinery, etc., which can solve the problems of not meeting the standard requirements of square paper cups, and the gap between the bottom corners and corners is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

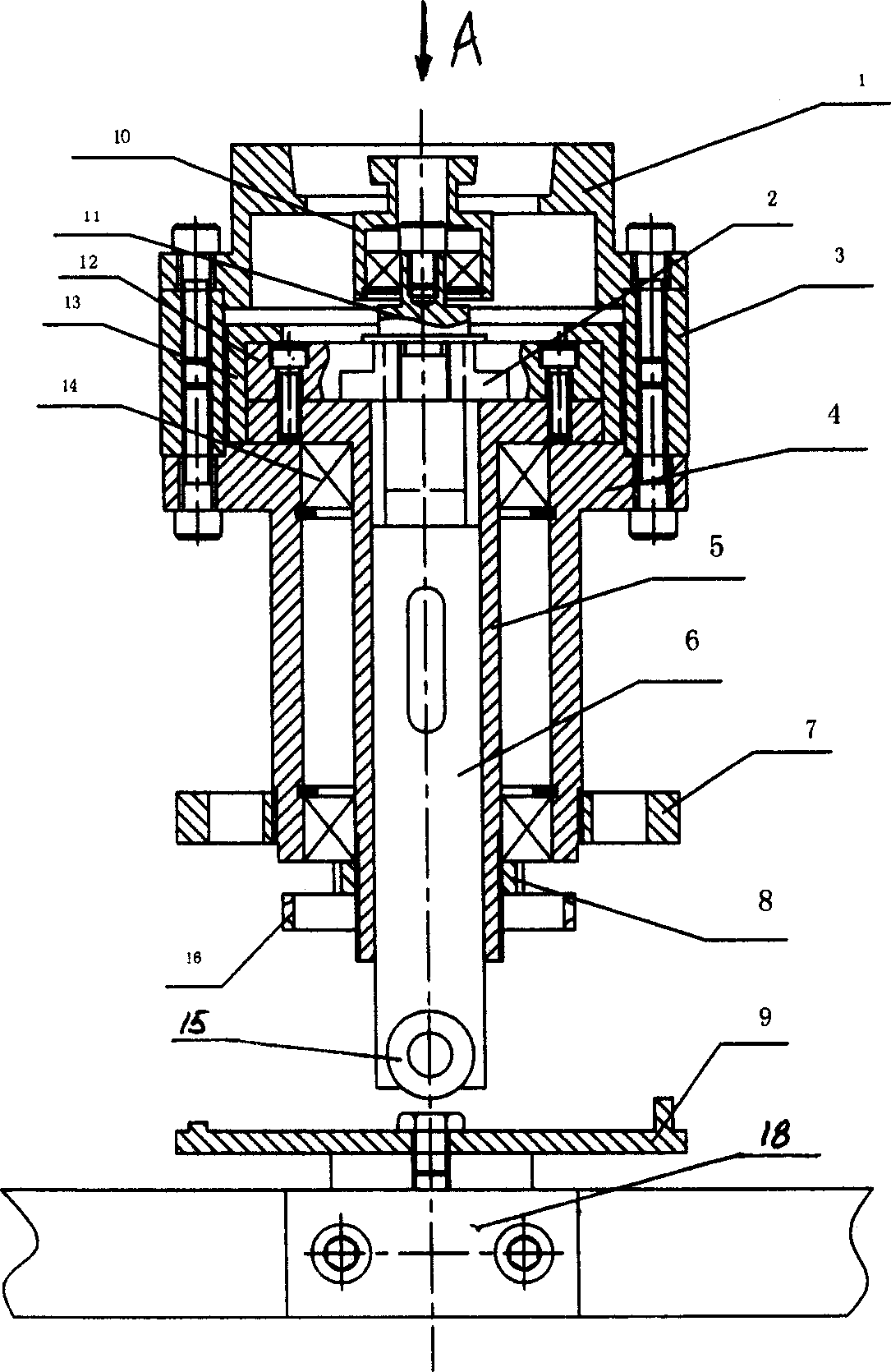

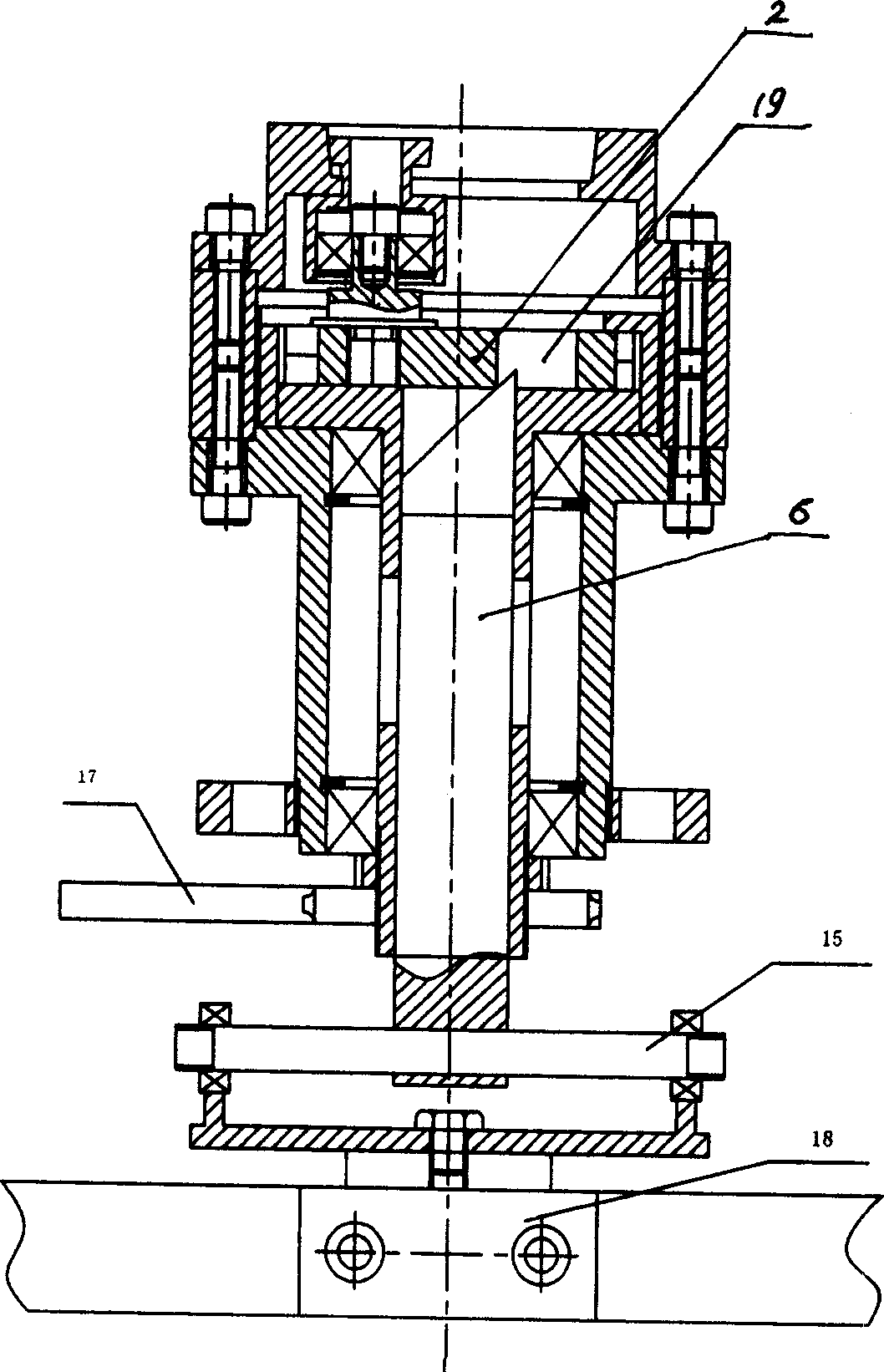

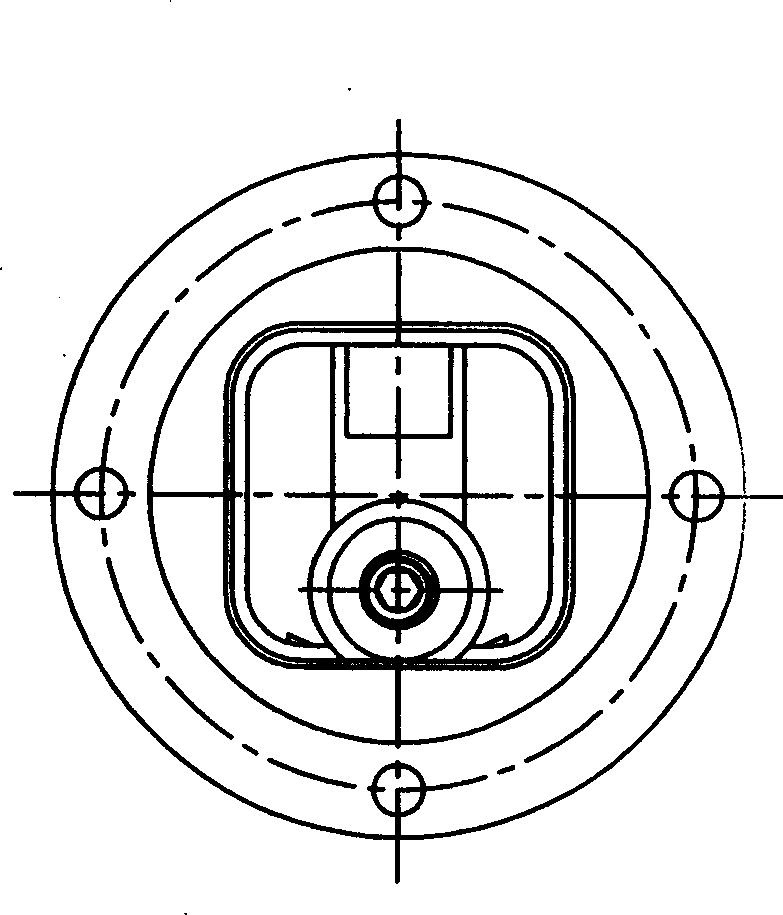

[0012] refer to figure 1 , figure 2 , image 3 It can be seen that the knurling device at the bottom of the square paper cup of the paper cup forming machine of the present invention includes a bottom-turning knurling sleeve 1, a slider 2, a raised ring 3, a knurling seat 4, a slider seat 5, a push rod 6, and a knurling wheel 10. , knurled wheel axle 11, the inner chamber of described bottom-turning knurled sleeve 1 is square angle shape (such as polygons such as quadrangle, hexagon, image 3 Shown is a quadrangular shape); the head of the ejector rod 6 has an inclined structure, the bottom of the ejector rod 6 is equipped with a cross bar 15, and a cam 9 is installed on the lifting base 18 of the paper cup forming machine, and the highest position of the cam 9 is The number of points corresponds to the number of the square corners of the inner cavity of the bottom-turning knurled sleeve 1 (as the inner cavity of the bottom-turning knurled sleeve is in a quadrangular shape,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com