Ion beam measuring method and ion implanting apparatus

一种离子注入装置、离子束的技术,应用在测量装置、照射装置、辐射的测量等方向,能够解决降低产率、结构复杂、增加成本等问题,达到减小额外时间、提高产率、简单构造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

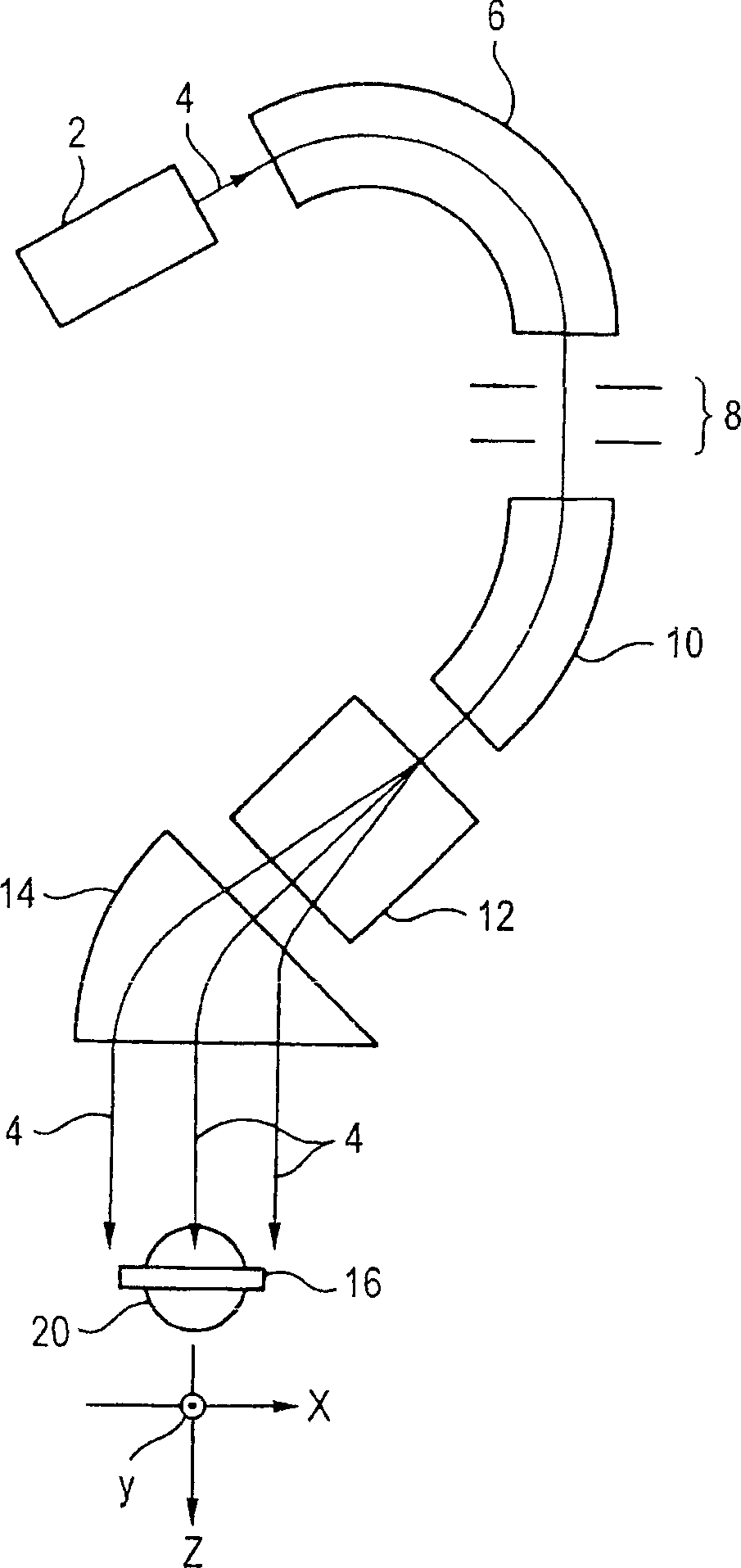

[0056] Figure 7 is a view showing an essential part of an embodiment of an ion implantation apparatus for realizing the ion beam measuring method according to the present invention. General structure reference of ion implantation equipment figure 1 and descriptions associated with it. Additionally, with figure 1 The same or corresponding parts in the illustrated examples are denoted by the same symbols, and in the following, differences from the above examples will be mainly explained.

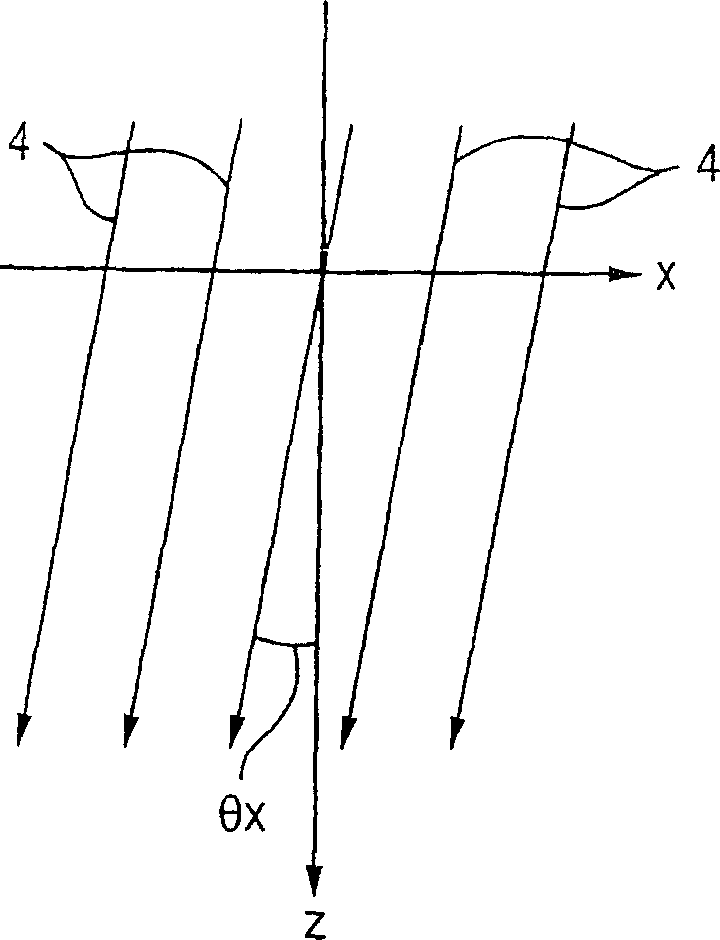

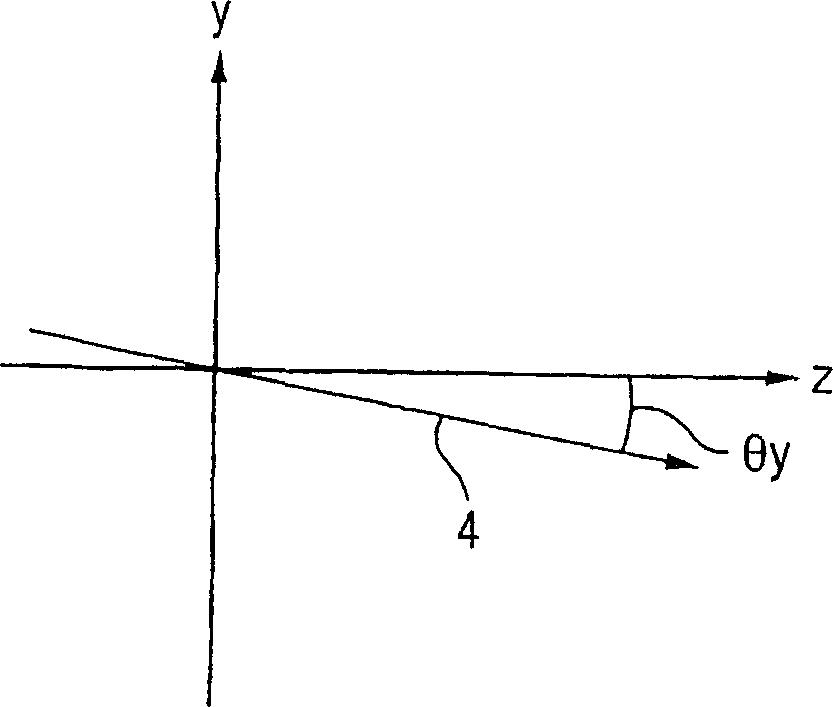

[0057] The ion implanter includes a position z on the upstream side of the target 16 ff The foreground multipoint Faraday 24 and the position z on the downstream side of the target 16 fb The multi-point Faraday 24 in the background, the position is the position relative to the z-axis constituting the advancing direction of the ion beam 4 . The z-axis position of the target 16 is marked by z t express. When target 16 as Figure 7 When the example shown is tilted, the z-axis position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com