Functionalisation (epoxidation) of silicones and use of said silicones as non-stick coatings

A technology of organosilicon compound and functionalization, applied in the direction of organic chemistry, silicon organic compounds, chemical instruments and methods, etc., can solve the problems of unrealistic economy, high cost of catalytic complexes, high cost of industrial implementation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

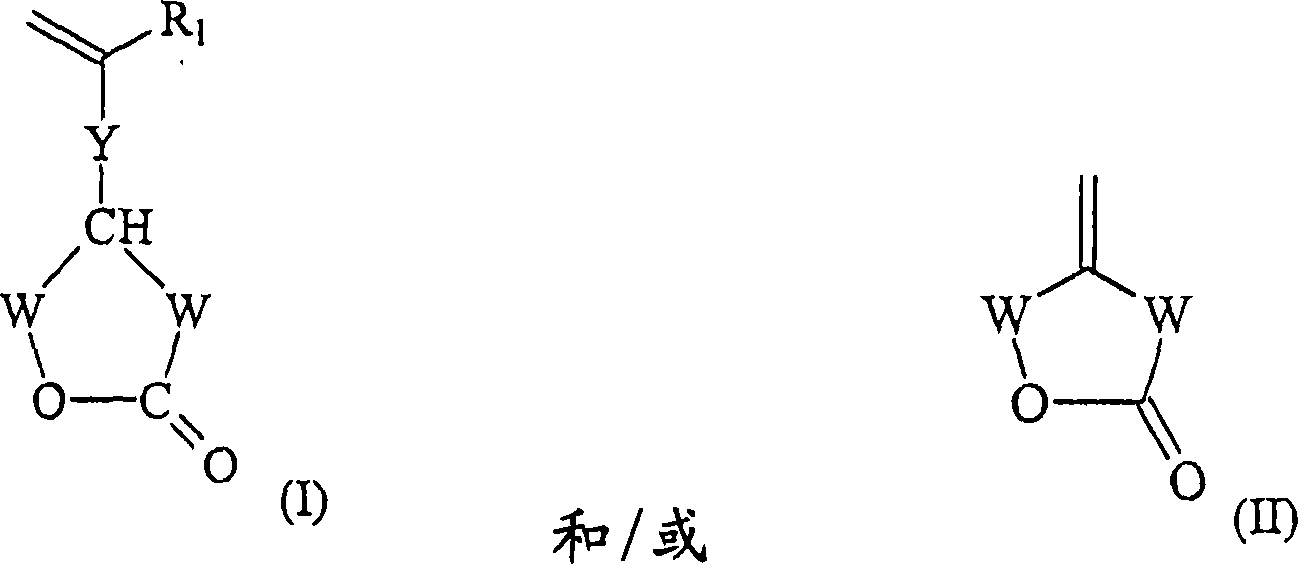

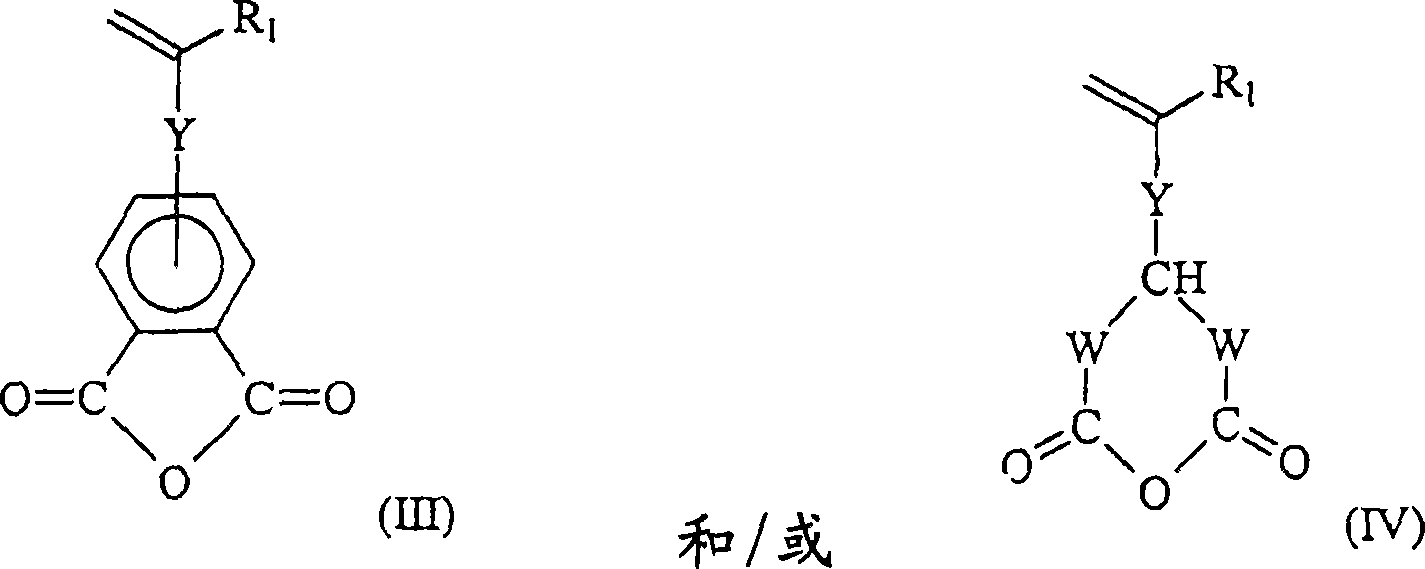

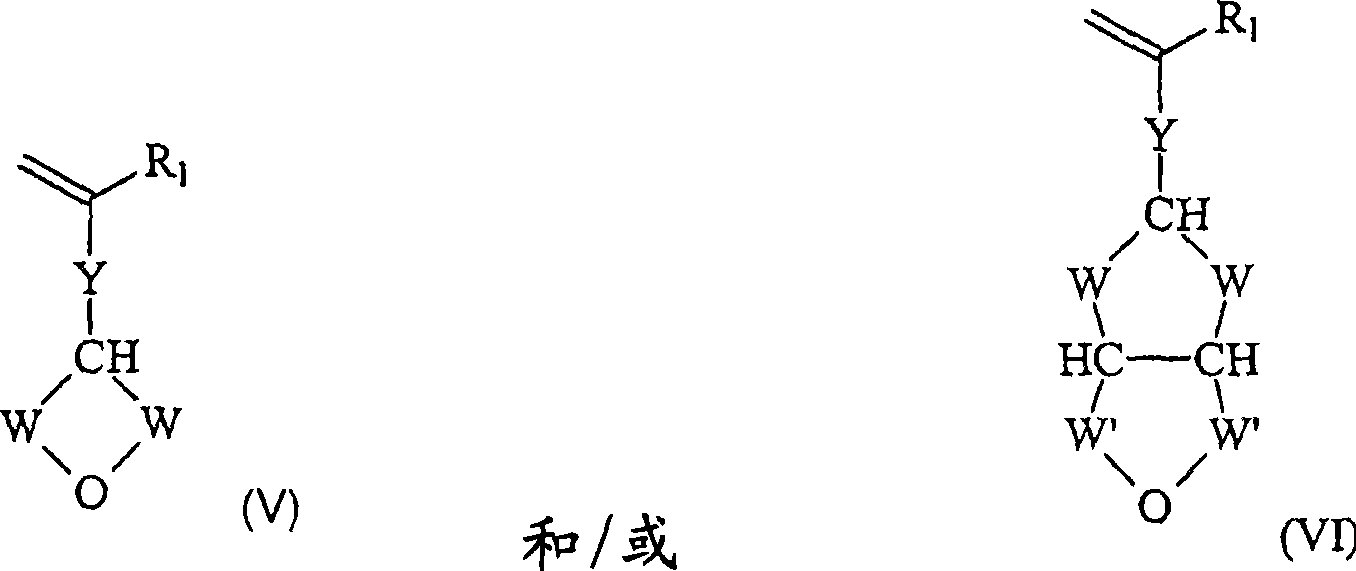

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0123] The 4-vinylcyclohexene epoxide (VCMX) used in the following examples was from Union Carbide. It is systematically distilled before use.

[0124] Tetramethylhydrogendisiloxane used (M' 2 ) are manufactured by Rhodia Silicones. It is also distilled itself before use.

[0125] Pt-coated carbon black catalyst (wet) was purchased from Aldrich Company under designation 33015-9. The content of platinum was 2.5 wt%. The water content is about 50 wt%.

[0126] The functionalization assistant used was sodium bicarbonate (NaHCO 3 ).

[0127] Catalyst, NaHCO 3 and the amount of water relative to VCMX and M’ 2 expressed in terms of the total quality.

[0128] The epoxide functional groups are measured by means of potentiometric methods. The equipment used was a DL21 Mettler Apparatus equipped with Mettler Toledo DG 113 SC LiCl / EtOH, 1.0 M, combined electrodes. The titration solution was 0.1N perchloric acid in acetic acid.

[0129] General operating procedures for Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com