Buoyancy-type low temperature level meter

A deep-low temperature, buoyancy technology, applied in the direction of displaying liquid level indicator through pressure measurement, can solve the problems of inability to measure low-temperature liquid level, false liquid level rise and fall, etc., and achieve stable and reliable reading and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

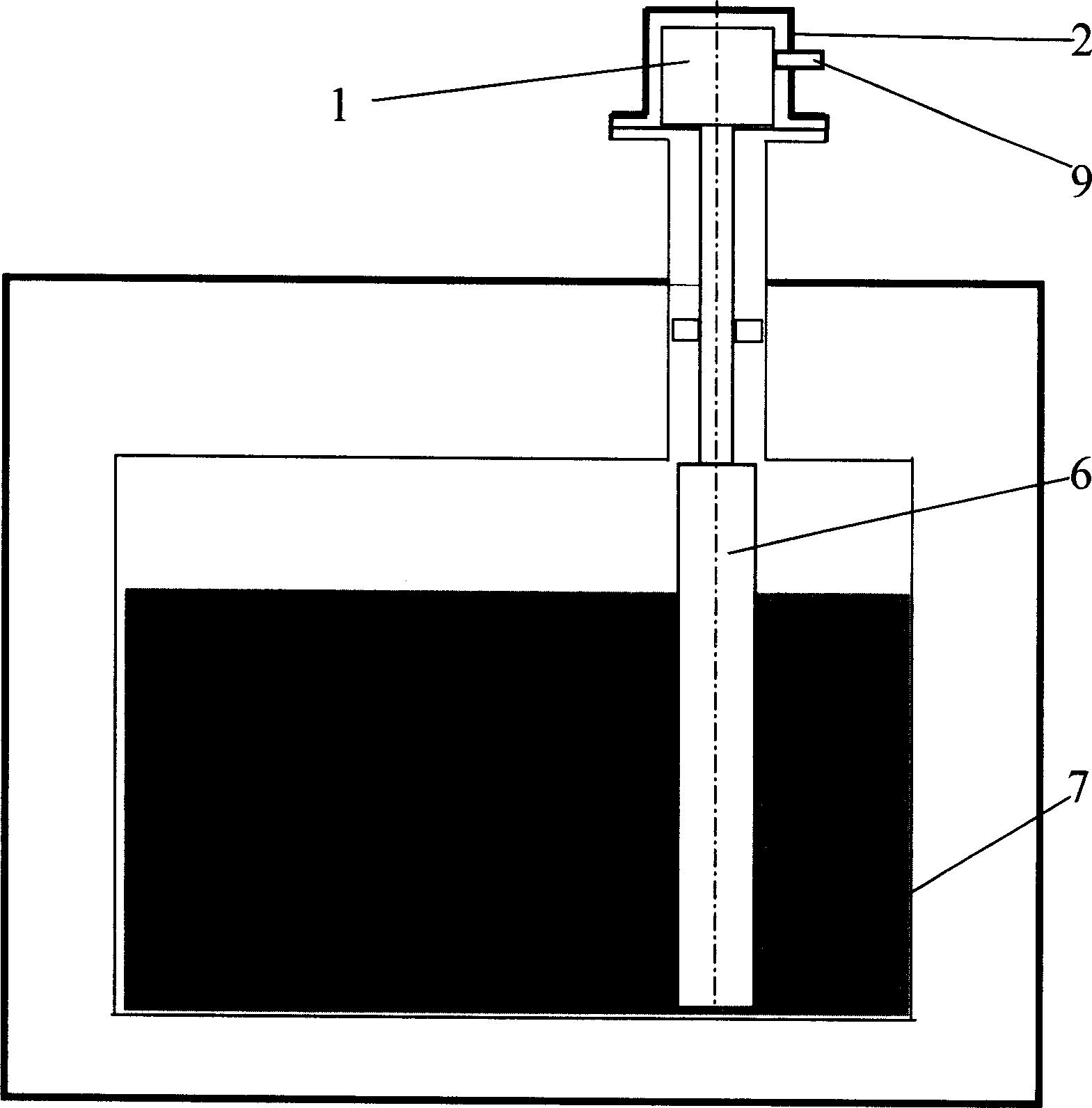

[0015] See attached figure 1 , 2 .

[0016] Labels in the figure: 1. Pull-pressure sensor, 2. Sensor sealing shell, 3. Flange, 4. Connecting rod of buoyancy probe, 5. Anti-decoration piece, 6. Buoyancy probe, 7. Liquid nitrogen tank, 8. Pressure bearing Shell, 9. Sensor signal line leading sealed socket, 10. Amplifier / transmitter, 11. Digital display instrument, 12. Data acquisition card.

[0017] The anti-swing piece 5 is a spacer with a hollow, and the connecting rod 4 is made of an epoxy tube, and the anti-swinging piece 5 prevents the connecting rod 4 from swinging. The buoyancy probe 6 is a hollow stainless steel cylinder fixedly connected with the connecting rod 4 and located in the liquid nitrogen tank 7, which has a pressure-bearing shell 8 outside the liquid nitrogen tank 7. The upper end of the connecting rod 4 is installed on the tension-compression sensor 1 . On the one hand, the flange 3 installs the shell 2, and on the other hand, it also provides a support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com