Bulking mud special fertilizer for poplar and its producing method

A special fertilizer and sludge technology, which is applied in the field of poplar special fertilizer production of expanded sludge, can solve the problems of lack of poplar special fertilizer, and achieve the effects of promoting sludge resource utilization, reducing plasticity, and shortening harvesting cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Example 1, the basic type of afforestation of young seedlings of the year

[0020] (1) Standard: organic matter ≥ 30%, N+P 2 o 5 +K 2 O≥15.0%

[0021] Heavy metals meet the requirements of GB4284-84.

[0022] (2) Formulation:

[0023] ① Sludge accounts for 41%;

[0024] ②Organic material 35%;

[0025] ③ 4% compound starter;

[0026] ④ Urea 6%;

[0027] ⑤Diammonium phosphate 10%;

[0028] ⑥Potassium sulfate or potassium chloride potassium fertilizer 4%;

example 2

[0029] Example 2, 3-4 years old poplar special type

[0030] (1) Standard: organic matter ≥ 20%, N+P 2 o 5 +K 2 O≥20%, heavy metals meet the requirements of GB4284-84.

[0031] (2) Formula

[0032] ① Sludge accounts for 45%;

[0033] ②Organic materials 25%;

[0034] ③Urea accounts for 10%;

[0035] ④ diammonium phosphate accounted for 10%;

[0036] ⑤Potassium sulfate or potassium chloride potassium fertilizer accounts for 5%;

[0037] ⑥ Composite fermentation agent accounts for 5%.

example 3

[0038] Example 3, 5-7 years old poplar special type

[0039] (1) Standard:

[0040] Organic matter ≥ 20%, N+P 2 o 5 +K 2 O≥20%, heavy metals meet the requirements of GB4284-84.

[0041] (2) Formula

[0042] ① Sludge accounts for 45%;

[0043] ② Organic materials 20%;

[0044] ③Urea accounts for 12%;

[0045] ④Diammonium phosphate accounts for 8%;

[0046] ⑤ Ordinary calcium superphosphate 5%;

[0047] ⑥Potassium sulfate or potassium chloride potassium fertilizer accounts for 5%;

[0048] ⑦ Composite starter accounts for 5%.

[0049] Production method of expanded sludge poplar special fertilizer:

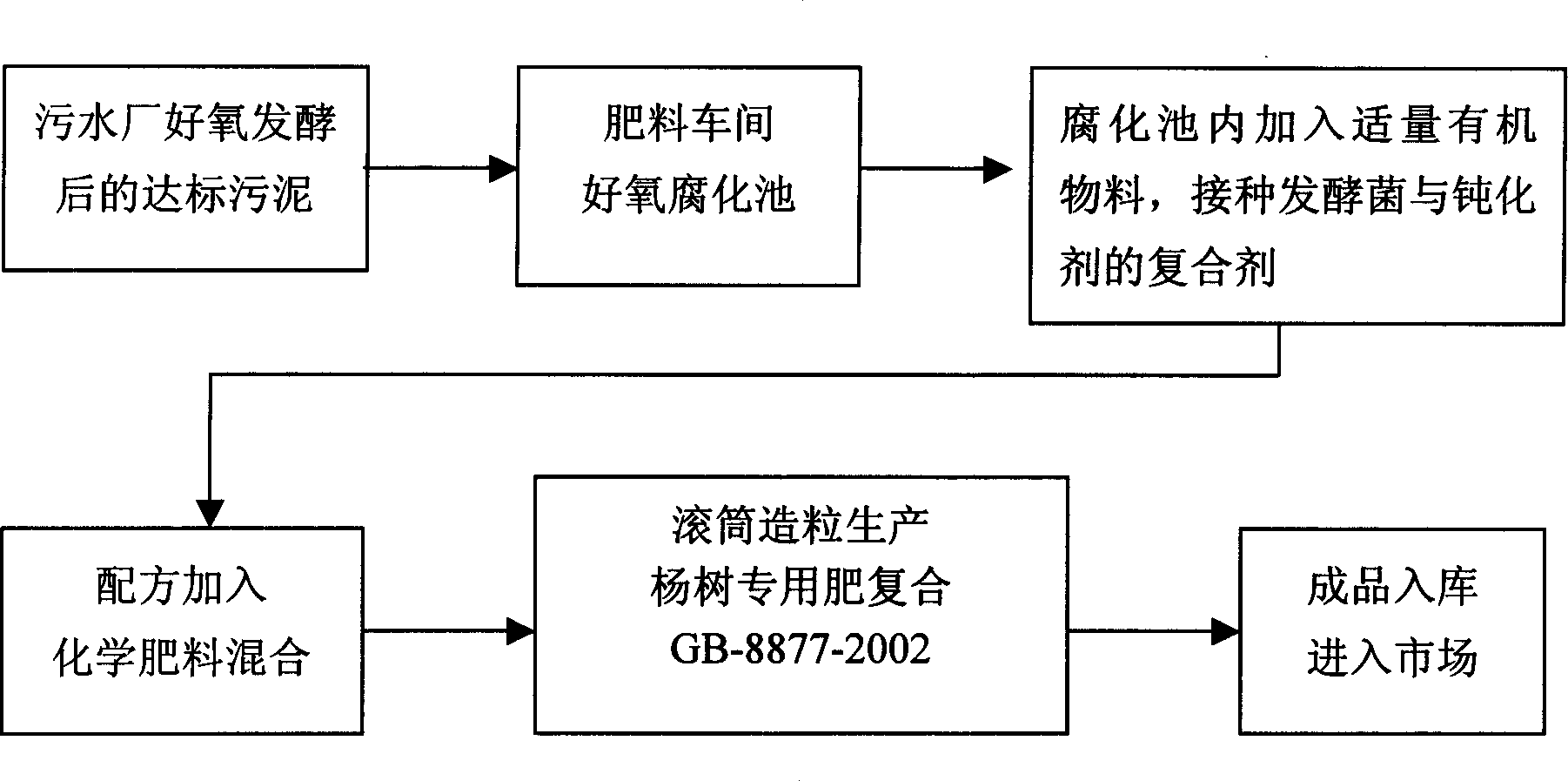

[0050] The sludge after detoxification by aerobic fermentation in the sewage plant is transferred to the fertilizer workshop and enters the second fermentation of aerobic decomposition in the septic tank. There is a ventilation and oxygen supply channel every 60cm in the tank, and organic materials are added. After mixing, the fermentation bacteria are inoculated and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com