Composite ingot set for continuous casting of Cu-Al bimetal in down-pulling reverse solidification process

A composite ingot and reverse solidification technology, applied in the field of casting devices, can solve the problems of difficult operation, difficult implementation, unsatisfactory coating effect, etc., and achieves the effect of good effect, easy operation, and preventing copper and aluminum delamination and fracture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

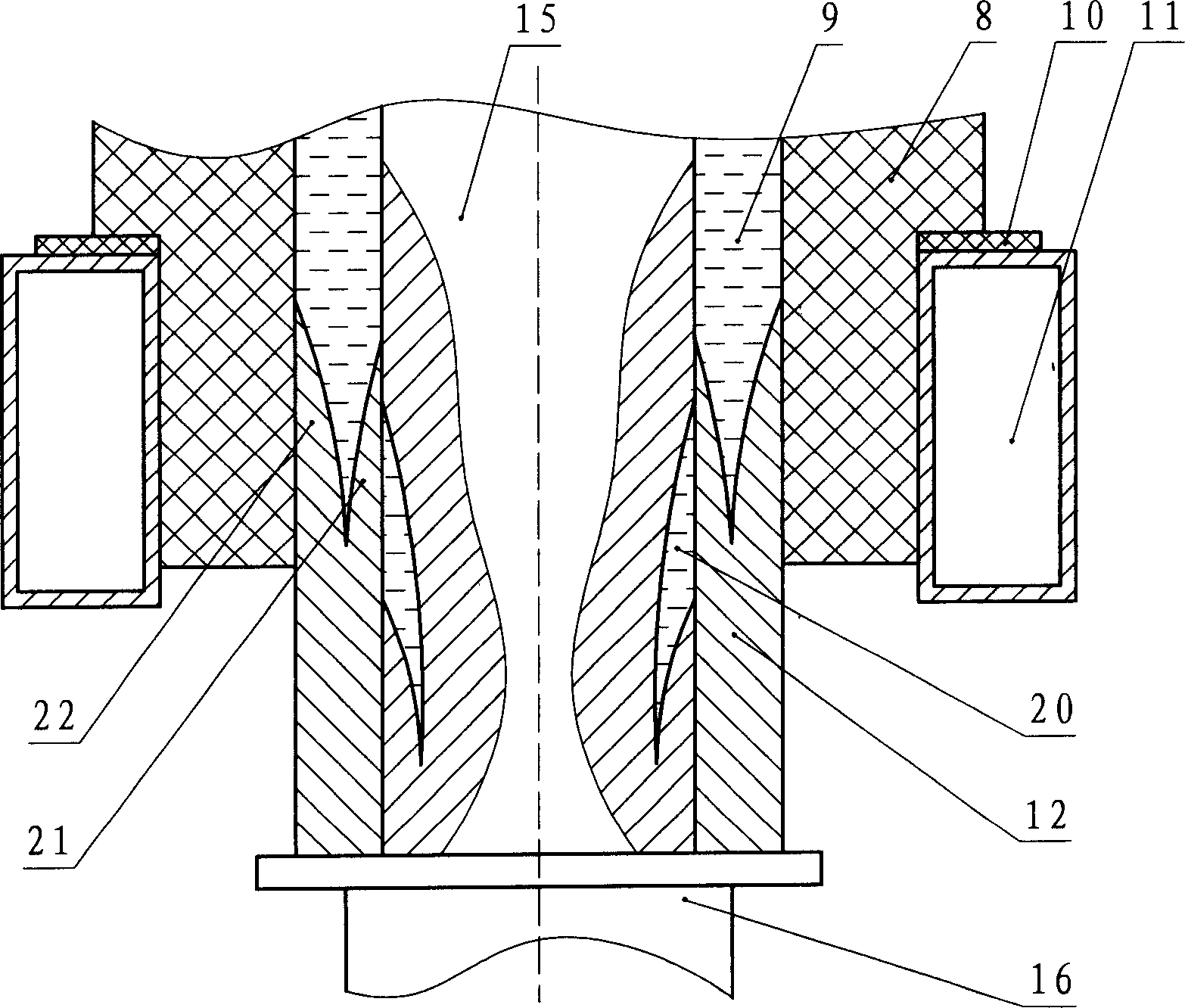

[0017] Such as figure 1 with figure 2 As shown, the present invention comprises a melting and holding furnace 5 and an ingot pulling device 18. There is a liquid outlet on the melting and holding furnace 5, and a crucible 8 is housed below the liquid outlet of the melting and holding furnace 5. Melt the outer skin composite material copper into copper liquid 9; a thermocouple 7 is also installed on the side of the melting and holding furnace 5 to measure the temperature of the copper liquid in the melting and holding furnace 5; Device 6, the heating and temperature regulating device 6 is a resistance heater, the heating and temperature regulating device 6 heats the copper liquid 9 in the crucible 8, and adjusts the temperature of the copper liquid 9 according to the process requirements; The crystallizer 11 is equipped with, and the crystallizer 11 is a cooling water jacket, and the crystallizer 11 carries out forced cooling to the lower part of the crucible 8, and the coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com