Diffraction optical component and its production

A technology for diffractive optical elements and manufacturing methods, applied in optical elements, diffraction gratings, optics, etc., can solve the problems of inability to mass-produce, complex steps, and large deviation of diffractive structures, and achieve automated mass production, improve qualification rate, The effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiment of the present invention discloses a diffractive optical element, and at the same time, the present invention also discloses a preferred manufacturing method for the diffractive element.

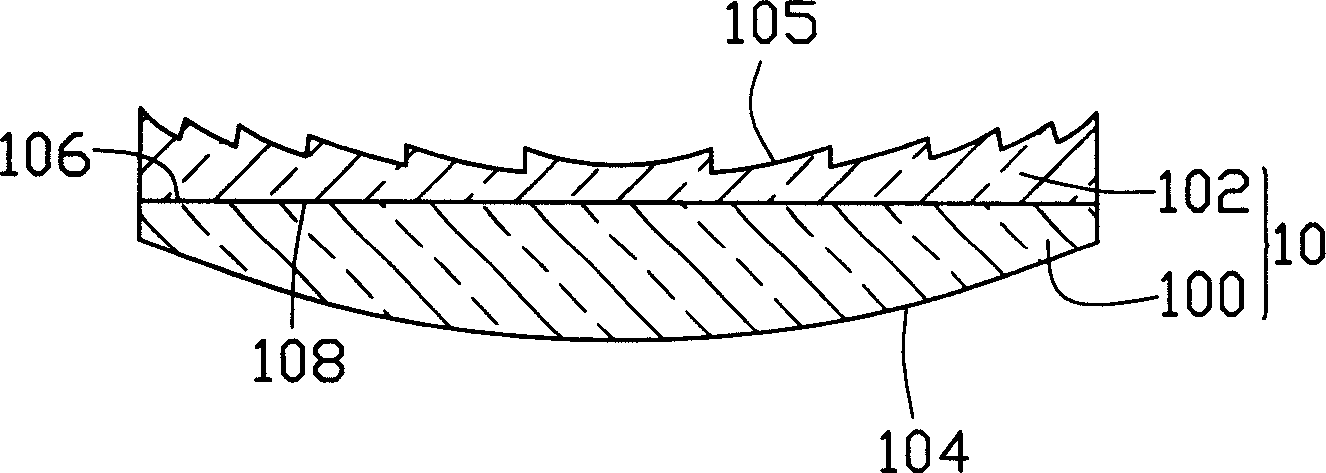

[0020] see figure 1 , the diffractive optical element 10 of the present invention includes an aspheric lens 100 and a diffractive grating 102 . The aspheric lens 100 includes an aspheric surface 104 and a first bonding surface 106 opposite to the aspherical surface 104 . The diffraction grating 102 includes a second bonding surface 108 and a diffraction surface 105 . The diffraction grating 102 is pasted on the first bonding surface 106 of the aspheric lens 100 through an adhesive having the same refractive index as the aspheric lens 100 , and the diffractive surface 105 faces outward.

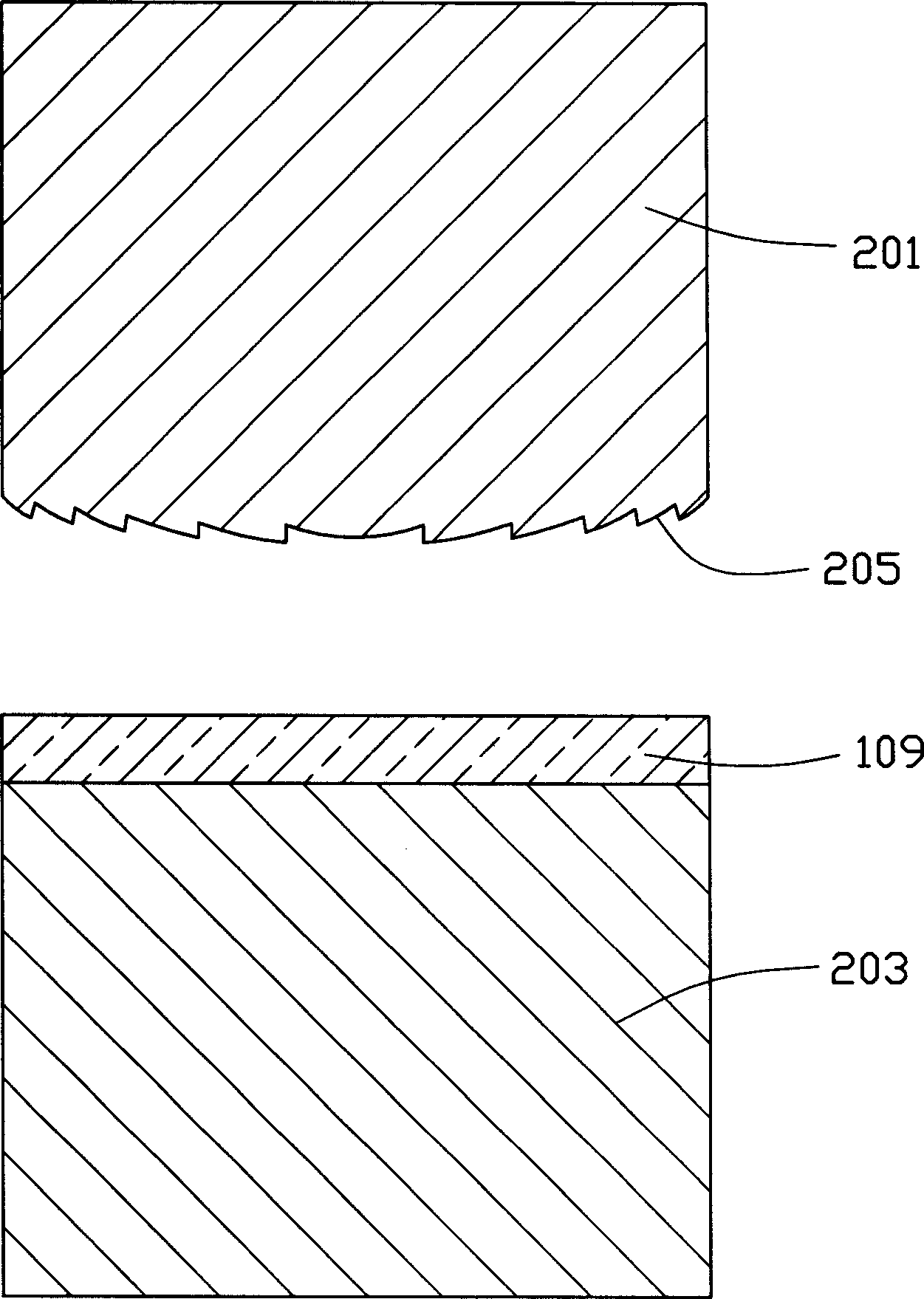

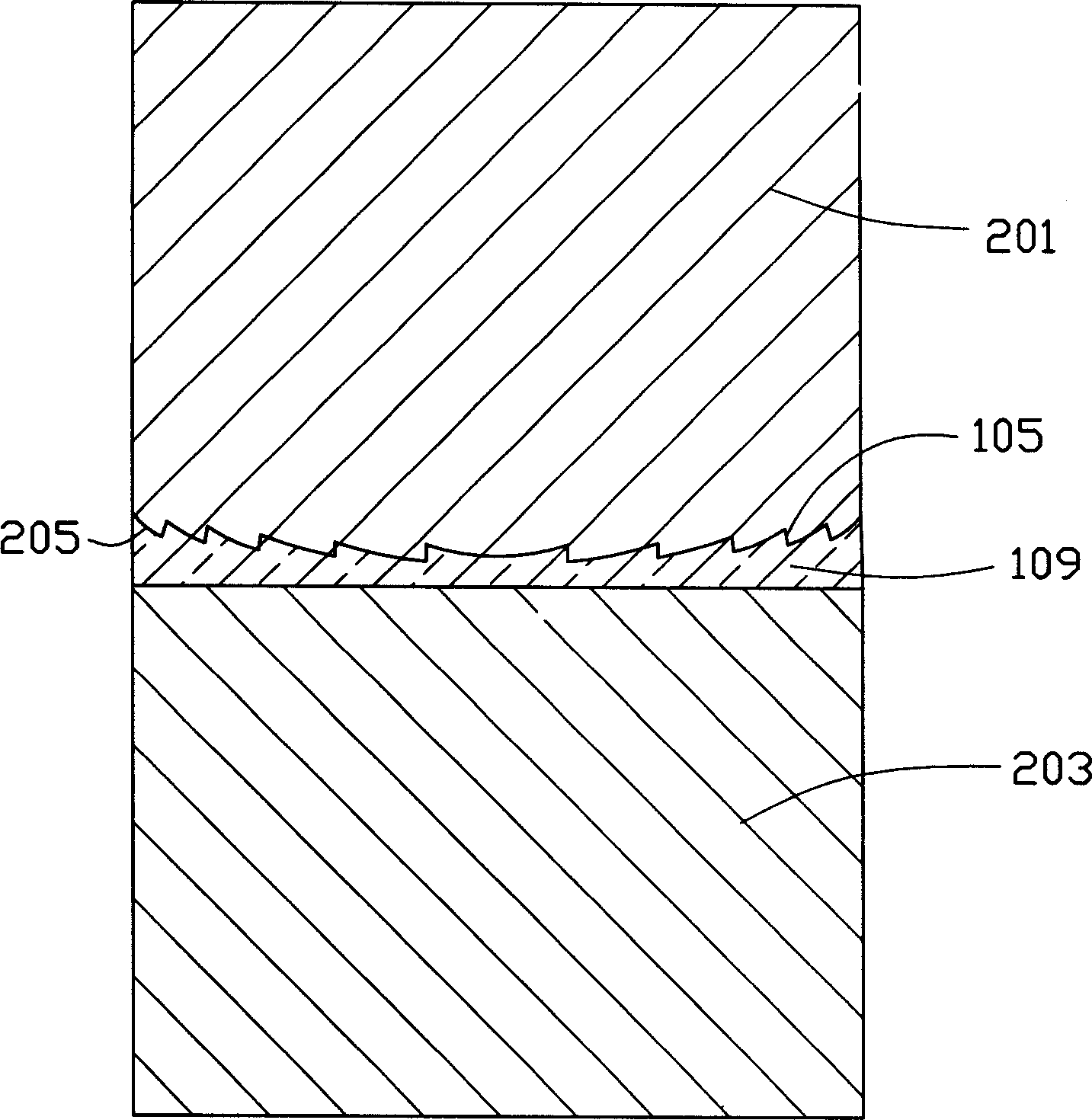

[0021] see figure 2 and image 3 , the first manufacturing method of the diffractive optical element 10 includes the following steps:

[0022] A mold is provided, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com