Workpiece transport device

A technology for conveying devices and workpieces, which can be used in conveyors, metal processing, manufacturing tools, etc., and can solve problems such as transmission speed limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

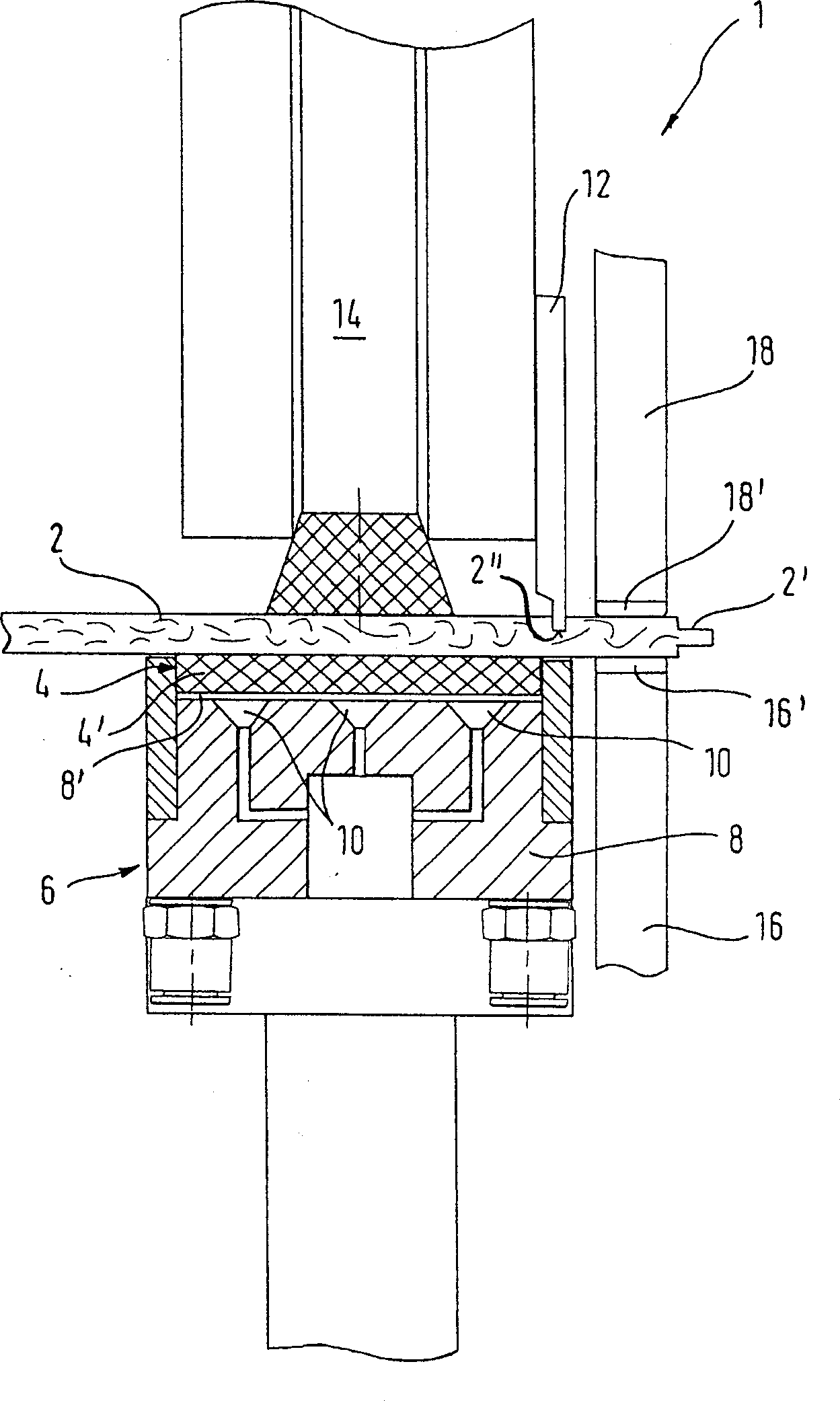

[0018] figure 1 A side view of a workpiece transfer device 1 as a preferred exemplary embodiment of the present invention is schematically shown. The workpiece transfer device 1 is used to transfer flat workpieces 2 to be processed during their passage through a forming machine designed to provide the exposed sides 2' of the workpieces 2 with, for example, tenons and grooves or "detents". "Forming processing of engaging elements such as.

[0019] figure 1 The workpiece transfer device 1 shown comprises an endless endless conveyor belt 4, figure 1 Only the upper strand 4' of the belt is shown, which is designed to store and transport the workpieces 2 to be transported by means of friction. The conveyor belt 4 is guided on a fixed guide 6 having a guide rail 8 holding the upper strand 4' along the conveyor track. The guide rail 8 has on its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com