A method and a system for producing an object using solid freeform fabrication

An object, free technology, used in machining, tooling, additive manufacturing, etc., to solve problems such as difficult to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

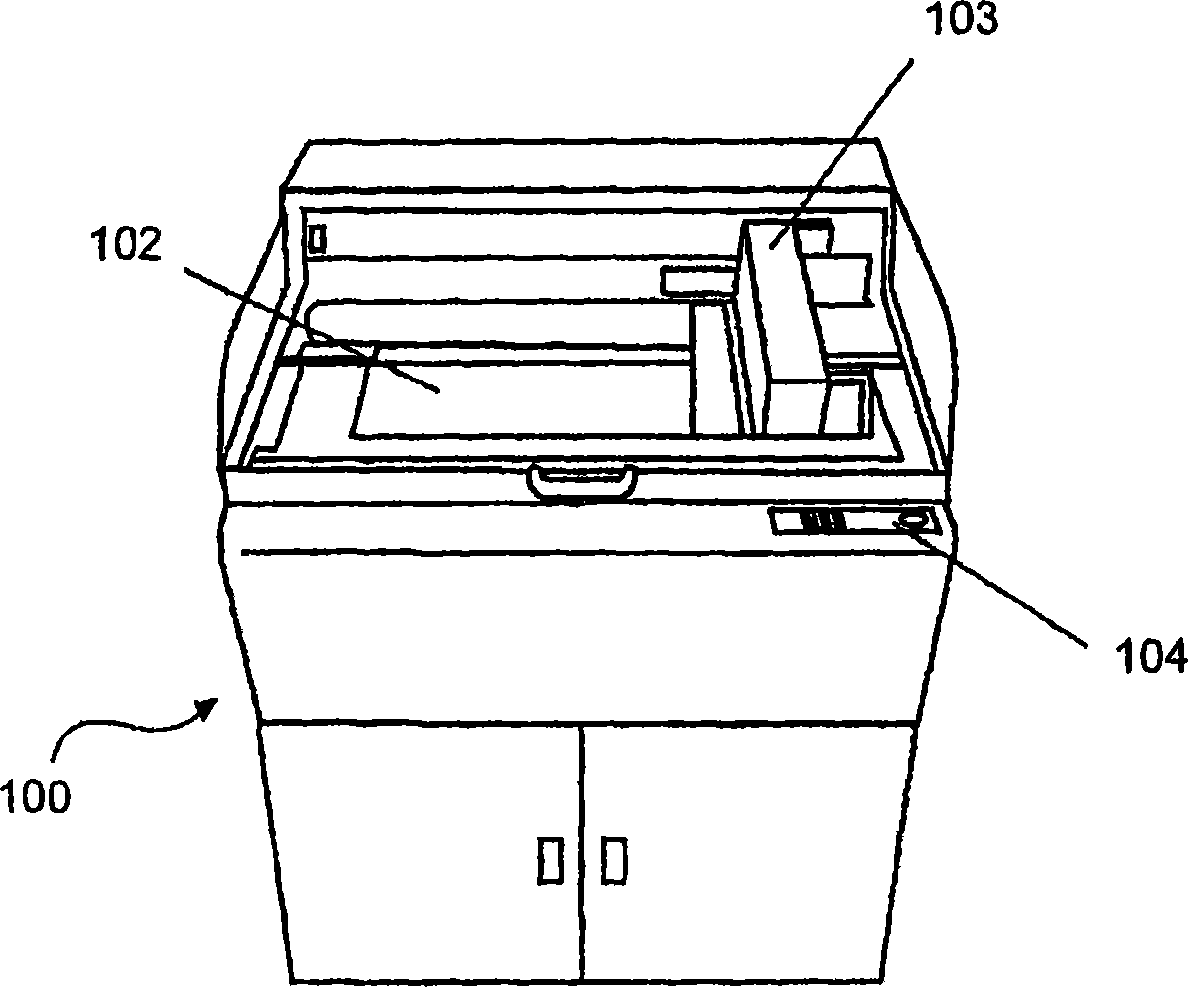

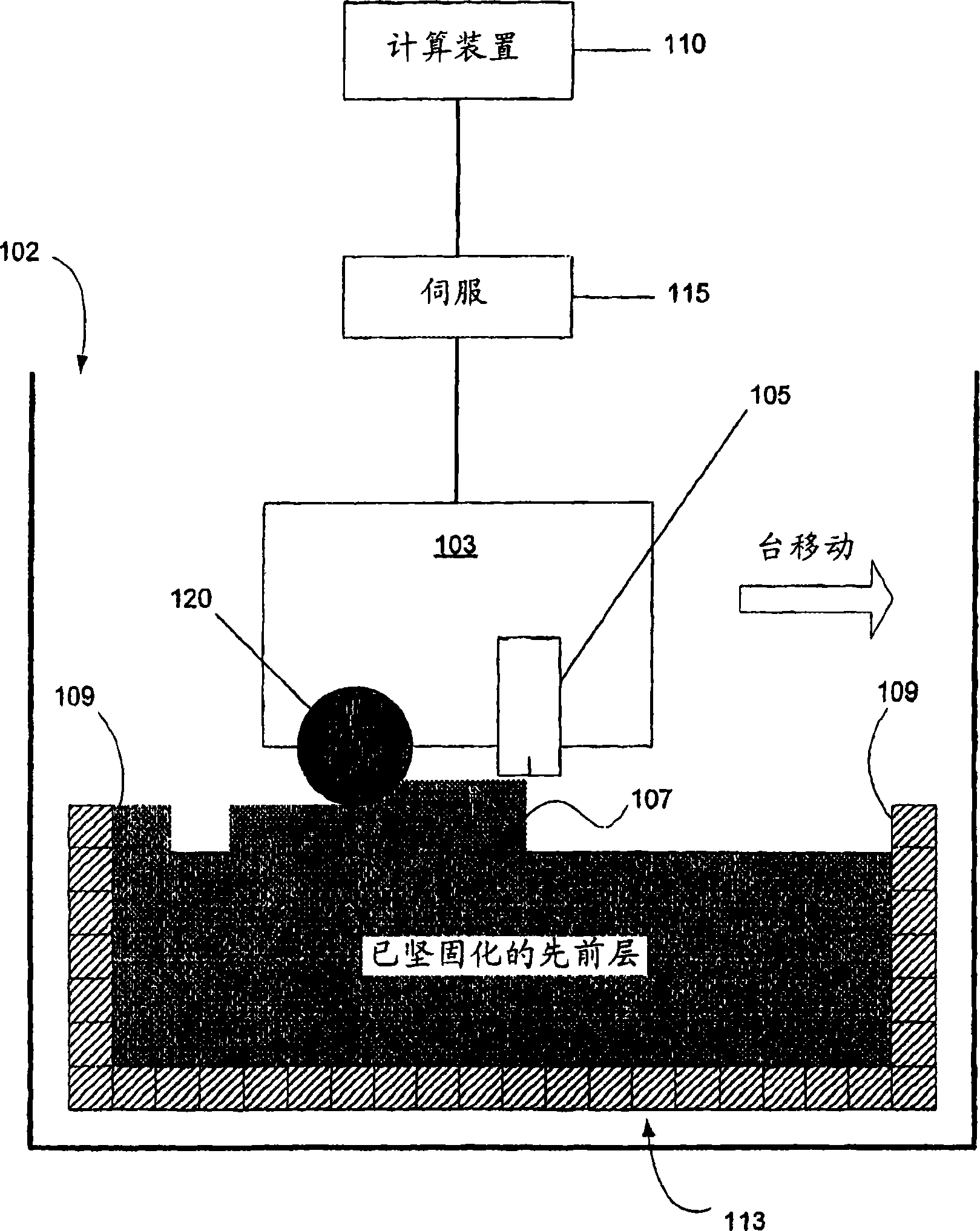

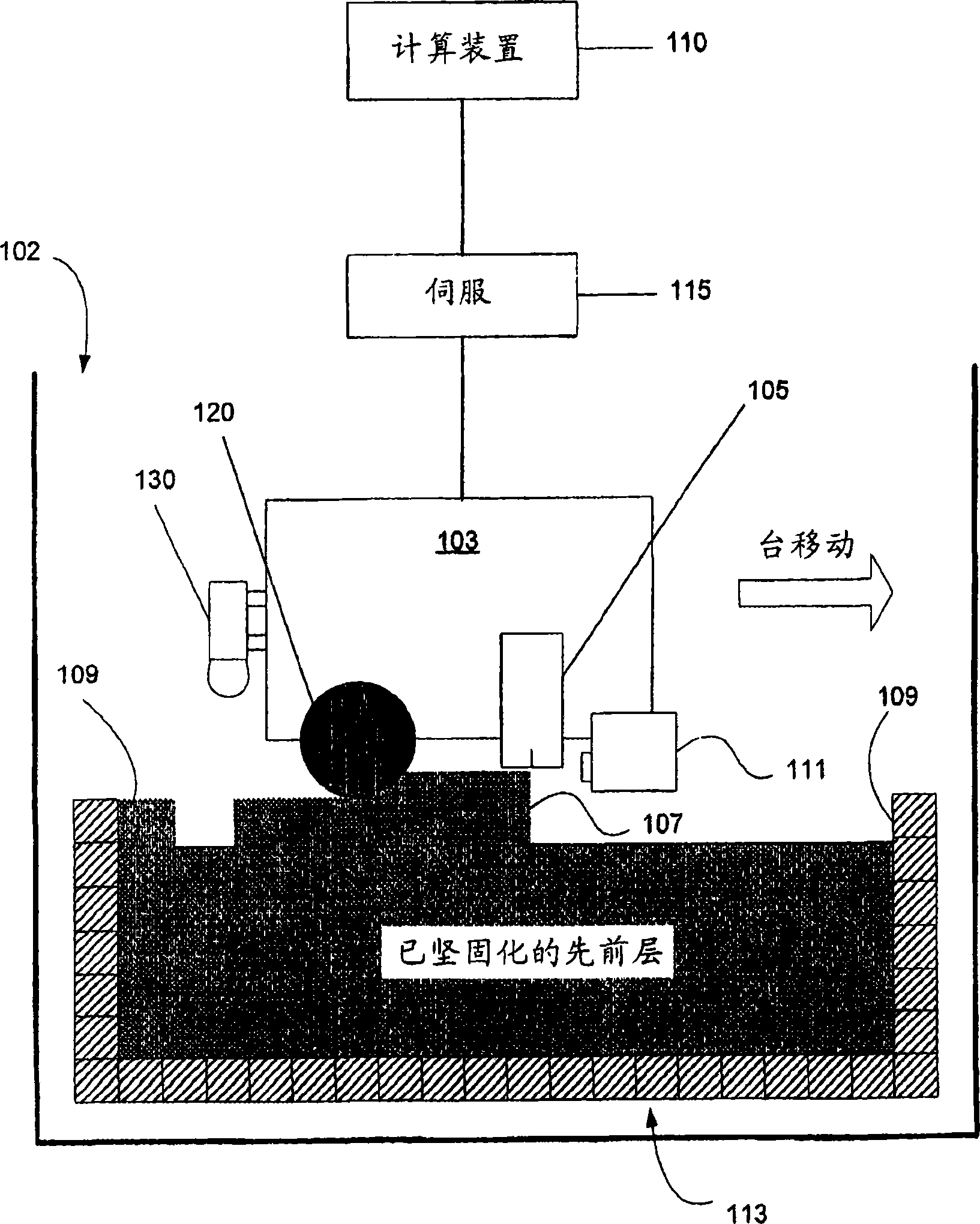

[0021] A method and apparatus for creating objects by selective boundary deposition using a solid freeform fabrication system is described herein. More specifically, a method for forming boundary structures using a high precision process and depositing a flowable build material using a low precision process is described.

[0022] As used in this specification and the appended claims, the term "high precision disperser" should be interpreted broadly as any dispersion device configured to perform a high precision process. Alternatively, the term "low-precision disperser" refers to a dispersing device configured to spray material in a low-precision process, and which, in some cases, may spray a continuous stream. Additionally, a single material disperser may be configured to selectively operate as both a high precision disperser and a low precision disperser. "Stream" or "continuous flow" should be broadly understood to include a fluid flow that is not defined by individual drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com