Automatic feeding device for lathe

An automatic feeding and lathe technology, which is applied in the field of automatic feeding devices for lathes that transport rods/tubes, can solve problems such as poor stability, large vibration effects, and abnormal conveying of rods, and achieve low working noise, less disturbance, and less The effect of human involvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

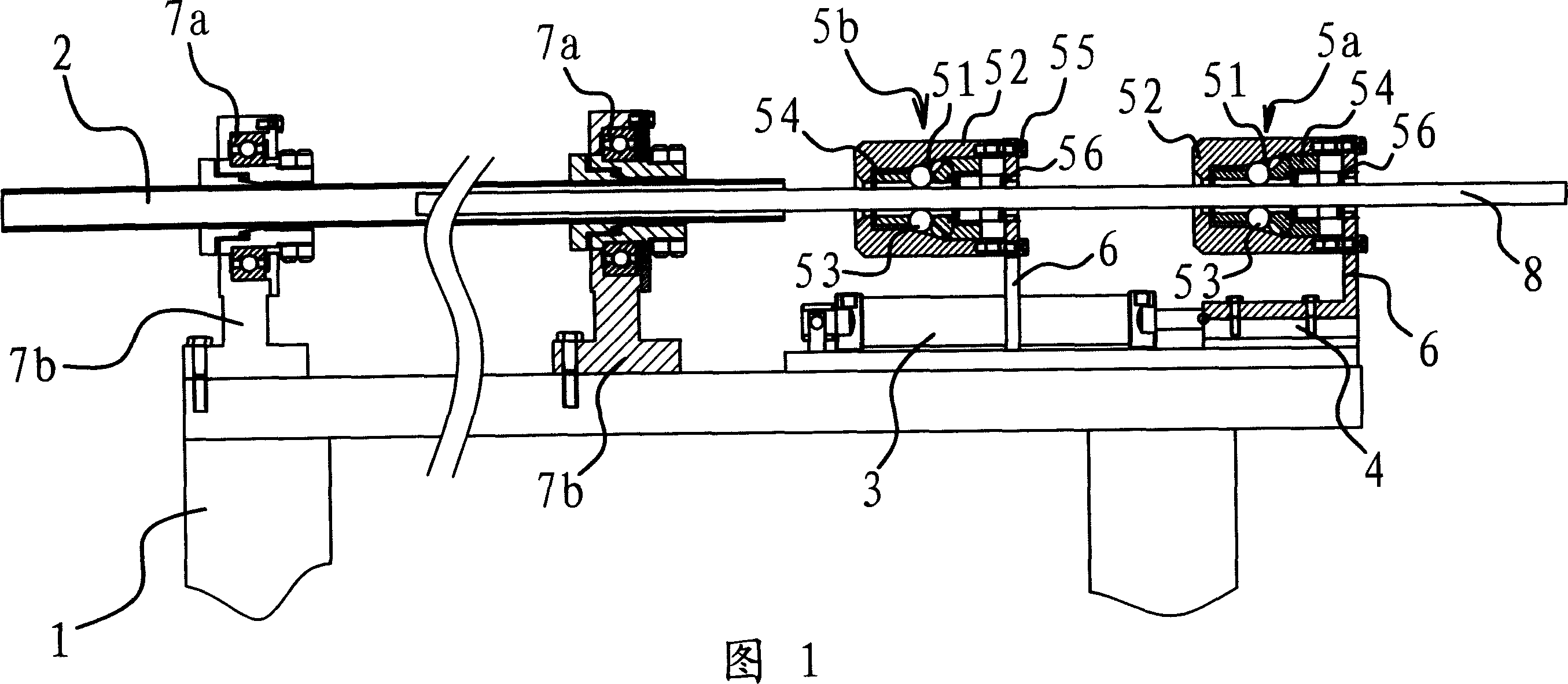

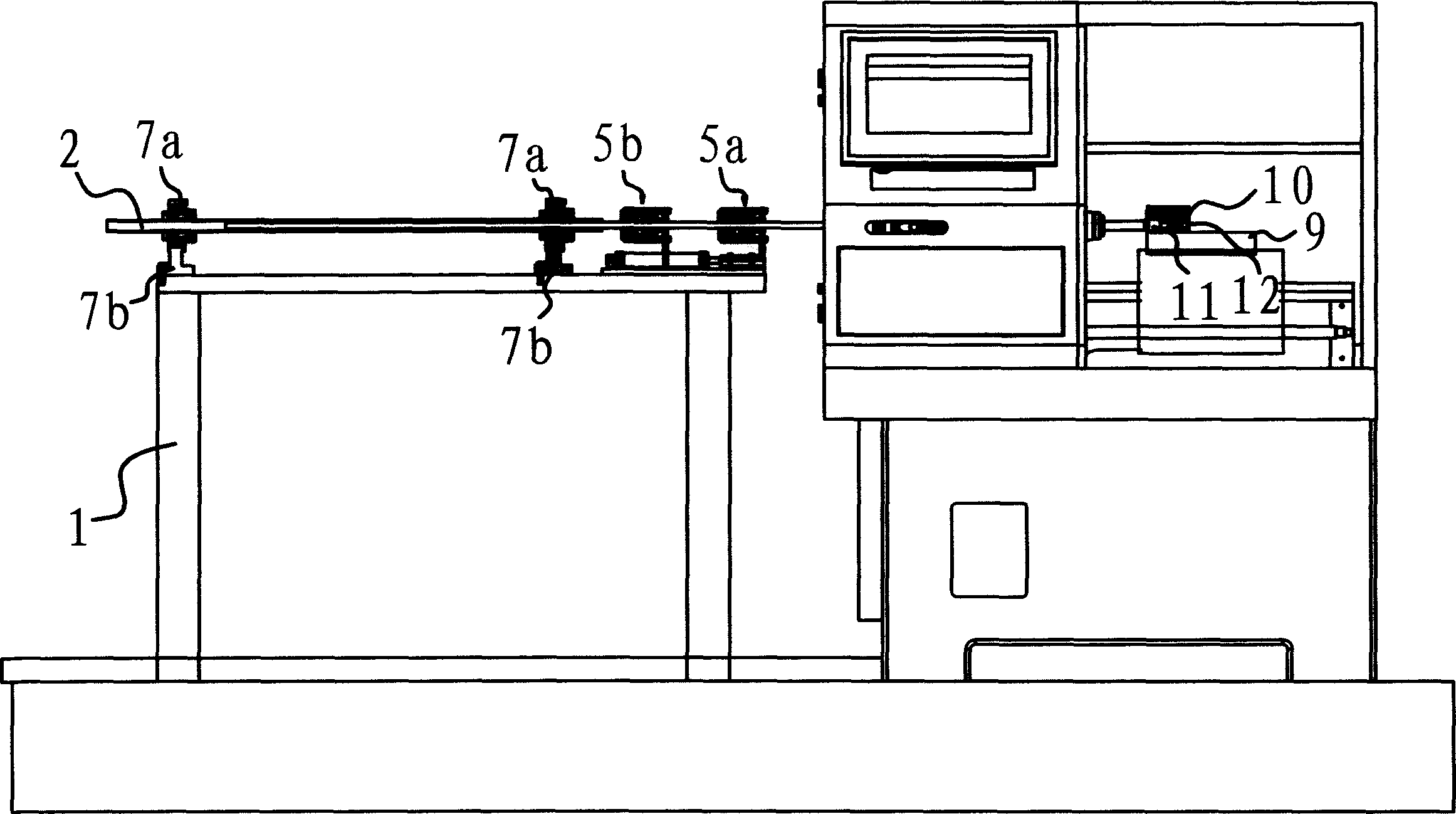

[0020] Figure 1 and image 3 As shown, the automatic feeding device of the lathe is set next to the workpiece chuck of the lathe, including the supporting tube 2 erected on the frame 1, the feeding cylinder 3, the slide plate 4, the moving feeder 5a, the fixed feeder 5b and other components.

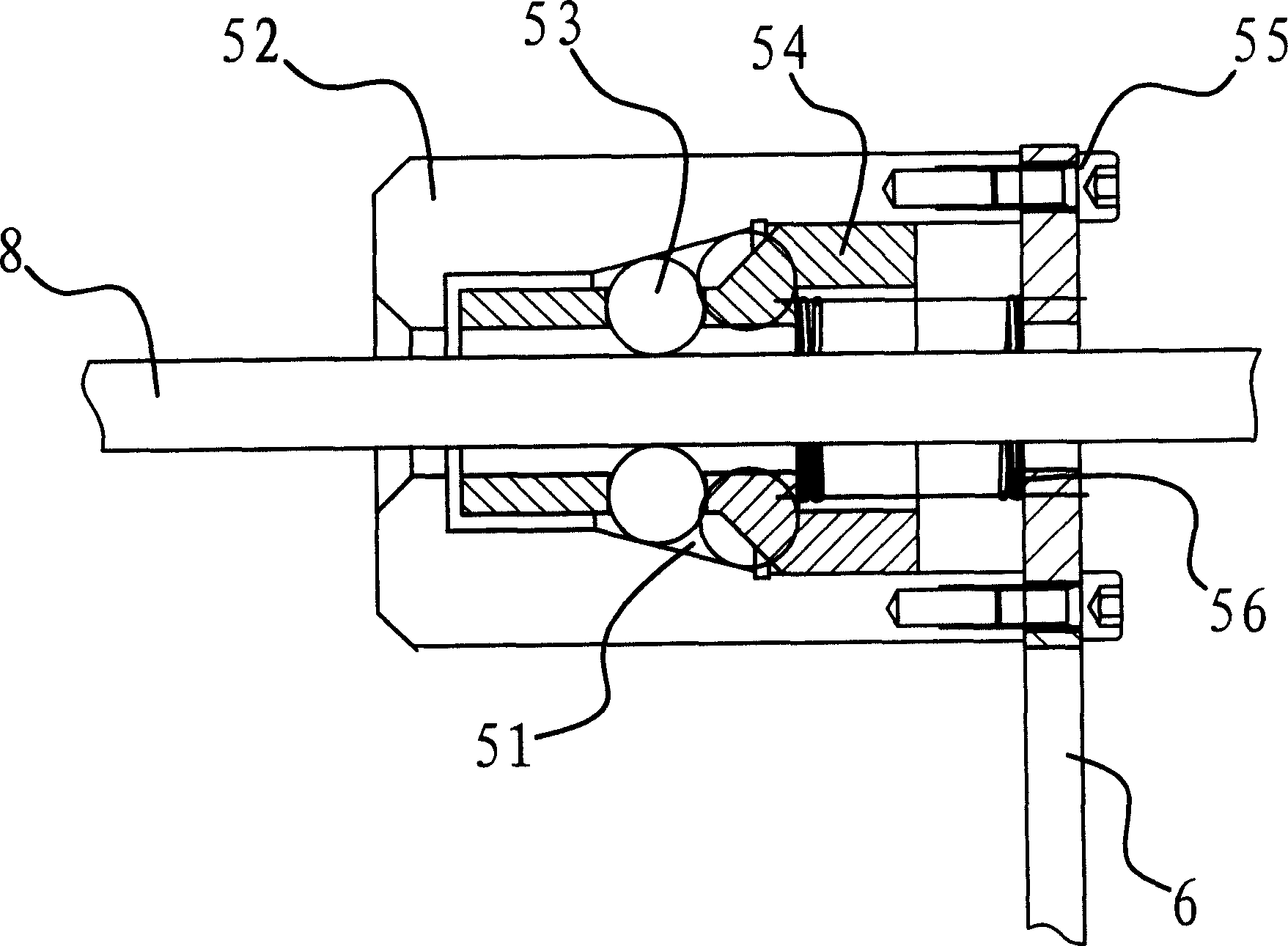

[0021] A feeding cylinder 3 is arranged on one side of the feeding tube 2 , and a slide plate 4 that can move axially along the feeding tube 2 is fixedly connected to the feeding cylinder 3 . The material holding tube 2 is arranged on the bracket 7b through the bearing 7a, and the inner wall of the material holding tube 2 is made of elastic material. The feeding tube 2 can absorb the impact of the vibration of the bar 8 and eliminate noise. On the other hand, the friction between the rod 8 and the holder 2 can be used to drive the holder 2 to rotate on the support 7b, reducing the frictional resistance of the rotation of the rod 8 and reducing the vibration. The bar stock 8 and the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com